Article 300

General Requirements for Wiring Methods and Materials

300.1 Scope.

(A) All Wiring Installations.

This article covers general requirements for wiring methods and materials for all wiring installations unless modified by other articles in Chapter 3.

(B) Integral Parts of Equipment.

The requirements of this article are not intended to apply to the conductors that form an integral part of equipment, such as motors, controllers, motor control centers, or factory-assembled control equipment or listed utilization equipment.

(C) Metric Designators and Trade Sizes.

Metric designators and trade sizes for conduit, tubing, and associated fittings and accessories shall be in accordance with Table 300.1(C).

Table 300.1(C) Metric Designators and Trade Sizes.

| Metric Designator | Trade Size |

|---|---|

| 12 | 3/8 |

| 16 | 1/2 |

| 21 | 3/4 |

| 27 | 1 |

| 35 | l1/4 |

| 41 | 11/2 |

| 53 | 2 |

| 63 | 21/2 |

| 78 | 3 |

| 91 | 31/2 |

| 103 | 4 |

| 129 | 5 |

| 155 | 6 |

Note: The metric designators and trade sizes are for identification purposes only and are not actual dimensions.

300.3 Conductors.

(A) Single Conductors.

Single conductors specified in Table 310.4(1) shall only be permitted where installed as part of a recognized wiring method specified in Chapter 3.

Exception: Individual conductors shall be permitted where installed as separate overhead conductors in accordance with 225.6.

(B) Conductors of the Same Circuit.

All conductors of the same circuit and, where used, the grounded conductor and all equipment grounding conductors and bonding conductors shall be contained within the same raceway, conduit body, auxiliary gutter, cable tray, cablebus assembly, trench, cable, or cord unless otherwise permitted in accordance with 300.3(B)(1) through (B)(4).

(1) Paralleled Installations.

Conductors shall be permitted to be run in parallel in accordance with 310.10(G). The requirement to run all circuit conductors within the same raceway, auxiliary gutter, cable tray, trench, cable, or cord shall apply separately to each portion of the paralleled installation, and the equipment grounding conductors shall comply with 250.122. Connections, taps, or extensions made from paralleled conductors shall connect to all conductors of the paralleled set, grounded and ungrounded, as applicable. Parallel runs in cable trays shall comply with 392.20(C).

Exception: Conductors installed in nonmetallic raceways run underground shall be permitted to be arranged as isolated phase, neutral, and grounded conductor installations. The raceways shall be installed in close proximity, and the isolated phase, neutral, and grounded conductors shall comply with 300.20(B).

(2) Grounding and Bonding Conductors.

Equipment grounding conductors shall be permitted to be installed outside a raceway or cable assembly in accordance with 250.130(C) for certain existing installations or in accordance with 250.134, Exception No. 2, for dc circuits. Equipment bonding conductors shall be permitted to be installed on the outside of raceways in accordance with 250.102(E).

(3) Nonferrous Wiring Methods.

Conductors in wiring methods with a nonmetallic or other nonmagnetic sheath, where run in different raceways, auxiliary gutters, cable trays, trenches, cables, or cords, shall comply with 300.20(B). Conductors in single-conductor Type MI cable with a nonmagnetic sheath shall comply with 332.31. Conductors of single-conductor Type MC cable with a nonmagnetic sheath shall comply with 330.31, 330.116, and 300.20(B).

(4) Column-Width Panelboard Enclosures.

Where an auxiliary gutter runs between a column-width panelboard and a pull box, and the pull box includes neutral terminations, the neutral conductors of circuits supplied from the panelboard shall be permitted to originate in the pull box.

(C) Conductors of Different Systems.

(1) 1000 Volts AC, 1500 Volts DC, Nominal, or Less.

Conductors of ac and dc circuits rated 1000 volts ac, 1500 volts dc, nominal, or less shall be permitted to occupy the same equipment wiring enclosure, cable, or raceway. All conductors shall have an insulation rating equal to at least the maximum circuit voltage applied to any conductor within the enclosure, cable, or raceway.

Secondary wiring to electric-discharge lamps of 1000 volts ac, 1500 volts dc, or less, if insulated for the secondary voltage involved, shall be permitted to occupy the same luminaire, sign, or outline lighting enclosure as the branch-circuit conductors.

Informational Note No. 1: See 725.136(A) for Class 2 and Class 3 circuit conductors.

Informational Note No. 2: See 690.31(B) for photovoltaic source and output circuits.

300.4 Protection Against Physical Damage.

(A) Cables and Raceways Through Wood Members.

(1) Bored Holes.

In both exposed and concealed locations, where a cable- or raceway-type wiring method is installed through bored holes in joists, rafters, or wood members, holes shall be bored so that the edge of the hole is not less than 32 mm (11/4 in.) from the edges of the wood member. Where this distance cannot be maintained, the cable or raceway shall be protected from penetration by screws or nails by a steel plate(s) or bushing(s) at least 1.6 mm (1/16 in.) thick, and of appropriate length and width, installed to cover the area of the wiring.

Exception No. 1: Steel plates shall not be required to protect rigid metal conduit, intermediate metal conduit, rigid PVC conduit, RTRC, or electrical metallic tubing.

Exception No. 2: A listed and marked steel plate less than 1.6 mm (1/16 in.) thick that provides equal or better protection against nail or screw penetration shall be permitted.

(2) Notches in Wood.

Where there is no objection because of weakening the building structure, in both exposed and concealed locations, cables or raceways shall be permitted to be laid in notches in wood studs, joists, rafters, or other wood members where the cable or raceway at those points is protected from penetration by nails or screws by a steel plate at least 1.6 mm (1/16 in.) thick, and of appropriate length and width, installed to cover the area of the wiring. The steel plate shall be installed before the building finish is applied.

Exception No. 1: Steel plates shall not be required to protect rigid metal conduit, intermediate metal conduit, rigid nonmetallic conduit, or electrical metallic tubing.

Exception No. 2: A listed and marked steel plate less than 1.6 mm (1/16 in.) thick that provides equal or better protection against nail or screw penetration shall be permitted.

(B) Nonmetallic-Sheathed Cables and Electrical Nonmetallic Tubing Through Metal Framing Members.

(1) Nonmetallic-Sheathed Cable.

In both exposed and concealed locations where nonmetallic-sheathed cables pass through either factory- or field-punched, cut, or drilled slots or holes in metal members, the cable shall be protected by listed bushings or listed grommets covering all metal edges that are securely fastened in the opening prior to installation of the cable.

(2) Nonmetallic-Sheathed Cable and Electrical Nonmetallic Tubing.

Where nails or screws are likely to penetrate nonmetallic-sheathed cable or electrical nonmetallic tubing, a steel sleeve, steel plate, or steel clip not less than 1.6 mm (1/16 in.) in thickness shall be used to protect the cable or tubing.

Exception: A listed and marked steel plate less than 1.6 mm (1/16 in.) thick that provides equal or better protection against nail or screw penetration shall be permitted.

(C) Cables Through Spaces Behind Panels Designed to Allow Access.

Cables or raceway-type wiring methods, installed behind panels designed to allow access shall be supported according to their applicable articles.

(D) Cables and Raceways Parallel to Framing Members and Furring Strips.

In both exposed and concealed locations, where a cable- or raceway-type wiring method is installed parallel to framing members, such as joists, rafters, or studs, or is installed parallel to furring strips, the cable or raceway shall be installed and supported so that the nearest outside surface of the cable or raceway is not less than 32 mm (11/4 in.) from the nearest edge of the framing member or furring strips where nails or screws are likely to penetrate. Where this distance cannot be maintained, the cable or raceway shall be protected from penetration by nails or screws by a steel plate, sleeve, or equivalent at least 1.6 mm (1/16 in.) thick.

Exception No. 1: Steel plates, sleeves, or the equivalent shall not be required to protect rigid metal conduit, intermediate metal conduit, rigid nonmetallic conduit, or electrical metallic tubing.

Exception No. 2: For concealed work in finished buildings, or finished panels for prefabricated buildings where such supporting is impracticable, it shall be permissible to fish the cables between access points.

Exception No. 3: A listed and marked steel plate less than 1.6 mm (1/16 in.) thick that provides equal or better protection against nail or screw penetration shall be permitted.

(E) Cables, Raceways, or Boxes Installed in or Under Metal-Corrugated Roof Decking.

A cable, raceway, or box, installed in exposed or concealed locations under metal-corrugated sheet roof decking, shall be installed and supported so there is not less than 38 mm (11/2 in.) measured from the lowest surface of the roof decking to the top of the cable, raceway, or box. A cable, raceway, or box shall not be installed in concealed locations in metal-corrugated, sheet decking—type roof.

Informational Note: Roof decking material is often repaired or replaced after the initial raceway or cabling and roofing installation and might be penetrated by screws or other mechanical devices designed to provide "hold down" strength of the waterproof membrane or roof insulating material.

Exception No. 1: Rigid metal conduit and intermediate metal conduit, with listed steel or malleable iron fittings and boxes, shall not be required to comply with 300.4(E).

Exception No. 2: The 38 mm (11/2 in.) spacing is not required where metal-corrugated sheet roof decking is covered with a minimum thickness 50 mm (2 in.) concrete slab, measured from the top of the corrugated roofing.

(F) Cables and Raceways Installed in Shallow Grooves.

Cable- or raceway-type wiring methods installed in a groove, to be covered by wallboard, siding, paneling, carpeting, or similar finish, shall be protected by 1.6 mm (1/16 in.) thick steel plate, sleeve, or equivalent or by not less than 32-mm (11/4-in.) free space for the full length of the groove in which the cable or raceway is installed.

Exception No. 1: Steel plates, sleeves, or the equivalent shall not be required to protect rigid metal conduit, intermediate metal conduit, rigid PVC conduit, RTRC, or electrical metallic tubing.

Exception No. 2: A listed and marked steel plate less than 1.6 mm (1/16 in.) thick that provides equal or better protection against nail or screw penetration shall be permitted.

(G) Fittings.

Where raceways contain 4 AWG or larger insulated circuit conductors, and these conductors enter a cabinet, a box, an enclosure, or a raceway, prior to the installation of conductors, the conductors shall be protected in accordance with any of the following:

- An identified fitting providing a smoothly rounded insulating surface

- A listed metal fitting that has smoothly rounded edges

- Separation from the fitting or raceway using an identified insulating material that is securely fastened in place

- Threaded hubs or bosses that are an integral part of a cabinet, box, enclosure, or raceway providing a smoothly rounded or flared entry for conductors

Conduit bushings constructed wholly of insulating material shall not be used to secure a fitting or raceway. The insulating fitting or insulating material shall have a temperature rating not less than the insulation temperature rating of the installed conductors.

300.5 Underground Installations.

(A) Minimum Cover Requirements.

Direct-buried cable, conduit, or other raceways shall be installed to meet the minimum cover requirements of Table 300.5(A).

Table 300.5(A) Minimum Cover Requirements, 0 to 1000 Volts ac, 1500 Volts dc, Nominal, Burial in Millimeters (Inches).

| Location of Wiring Method or Circuit | Type of Wiring Method or Circuit | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Column 1 Direct Burial Cables or Conductors | Column 2 Rigid Metal Conduit or Intermediate Metal Conduit | Column 3 Electrical Metallic Tubing, Nonmetallic Raceways Listed for Direct Burial Without Concrete Encasement, or Other Approved Raceways | Column 4 Residential Branch Circuits Rated 120 Volts or Less with GFCI Protection and Maximum Overcurrent Protection of 20 Amperes | Column 5 Circuits for Control of Irrigation and Landscape Lighting Limited to Not More Than 30 Volts and Installed with Type UF or in Other Identified Cable or Raceway | ||||||

| mm | in. | mm | in. | mm | in. | mm | in. | mm | in. | |

| All locations not specified below | 600 | 24 | 150 | 6 | 450 | 18 | 300 | 12 | 1501,2 | 61,2 |

| In trench below 50 mm (2 in.) thick concrete or equivalent | 450 | 18 | 150 | 6 | 300 | 12 | 150 | 6 | 150 | 6 |

| Under a building | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| (in raceway or Type MC or Type MI cable identified for direct burial) | (in raceway or Type MC or Type MI cable identified for direct burial) | (in raceway or Type MC or Type MI cable identified for direct burial) | ||||||||

| Under minimum of 102 mm (4 in.) thick concrete exterior slab with no vehicular traffic and the slab extending not less than 152 mm (6 in.) beyond the underground installation | 450 | 18 | 100 | 4 | 100 | 4 | 150 (direct burial) | 6 | 150(direct burial) | 6 |

| 100(in raceway) | 4 | 100(in raceway) | 4 | |||||||

| Under streets, highways, roads, alleys, driveways, and parking lots | 600 | 24 | 600 | 24 | 600 | 24 | 600 | 24 | 600 | 24 |

| One- and two-family dwelling driveways and outdoor parking areas, and used only for dwelling-related purposes | 450 | 18 | 450 | 18 | 450 | 18 | 300 | 12 | 450 | 18 |

| In or under airport runways, including adjacent areas where trespassing is prohibited | 450 | 18 | 450 | 18 | 450 | 18 | 450 | 18 | 450 | 18 |

1A lesser depth shall be permitted where specified in the installation instructions of a listed low-voltage lighting system.

2A depth of 150 mm (6 in.) shall be permitted for pool, spa, and fountain lighting, installed in a nonmetallic raceway, limited to not more than 30 volts where part of a listed low-voltage lighting system.

Notes:

- Cover shall be defined as the shortest distance in mm (in.) measured between a point on the top surface of any direct-buried conductor, cable, conduit, or other raceway and the top surface of finished grade, concrete, or similar cover.

- Raceways approved for burial only where concrete encased shall require a concrete envelope not less than 50 mm (2 in.) thick.

- Lesser depths shall be permitted where cables and conductors rise for terminations or splices or where access is otherwise required.

- Where one of the wiring method types listed in Columns 1 through 3 is used for one of the circuit types in Columns 4 and 5, the shallowest depth of burial shall be permitted.

- Where solid rock prevents compliance with the cover depths specified in this table, the wiring shall be installed in a metal raceway, or a nonmetallic raceway permitted for direct burial. The raceways shall be covered by a minimum of 50 mm (2 in.) of concrete extending down to rock.

- Directly buried electrical metallic tubing (EMT) shall comply with 358.10.

(B) Wet Locations.

The interior of enclosures or raceways installed underground shall be considered to be a wet location. Insulated conductors and cables installed in these enclosures or raceways in underground installations shall comply with 310.10(C).

(C) Underground Cables and Conductors Under Buildings.

Underground cable and conductors installed under a building shall be in a raceway.

Exception No. 1: Type MI cable shall be permitted under a building without installation in a raceway where embedded in concrete, fill, or other masonry in accordance with 332.10(6) or in underground runs where suitably protected against physical damage and corrosive conditions in accordance with 332.10(10).

(D) Protection From Damage.

(1) Emerging From Grade.

Direct-buried conductors and cables emerging from grade and specified in Columns 1 and 4 of Table 300.5(A) shall be protected by enclosures or raceways extending from the minimum cover distance below grade required by 300.5(A) to a point at least 2.5 m (8 ft) above finished grade. In no case shall the protection be required to exceed 450 mm (18 in.) below finished grade.

(3) Service Conductors.

Underground service conductors that are not encased in concrete and that are buried 450 mm (18 in.) or more below grade shall have their location identified by a warning ribbon that is placed in the trench at least 300 mm (12 in.) above the underground installation.

(E) Splices and Taps.

Direct-buried conductors or cables shall be permitted to be spliced or tapped without the use of splice boxes. The splices or taps shall be made in accordance with 110.14(B).

(F) Backfill.

Backfill that contains large rocks, paving materials, cinders, large or sharply angular substances, or corrosive material shall not be placed in an excavation where materials might damage raceways, cables, conductors, or other substructures or prevent adequate compaction of fill or contribute to corrosion of raceways, cables, or other substructures.

(G) Raceway Seals.

Conduits or raceways through which moisture might contact live parts shall be sealed or plugged at either or both ends. Spare or unused raceways shall also be sealed. Sealants shall be identified for use with the cable insulation, conductor insulation, bare conductor, shield, or other components.

Informational Note: Presence of hazardous gases or vapors might also necessitate the sealing of underground conduits or raceways entering buildings.

(H) Bushing.

A bushing, or terminal fitting, with an integral bushed opening shall be used at the end of a conduit or other raceway that terminates underground where the conductors or cables emerge as a direct burial wiring method. A seal incorporating the physical protection characteristics of a bushing shall be permitted to be used in lieu of a bushing.

(I) Conductors of the Same Circuit.

All conductors of the same circuit and, where used, the grounded conductor and all equipment grounding conductors shall be installed in the same raceway or cable or shall be installed in close proximity in the same trench.

Exception No. 1: Conductors shall be permitted to be installed in parallel in raceways, multiconductor cables, or direct-buried single conductor cables. Each raceway or multiconductor cable shall contain all conductors of the same circuit, including equipment grounding conductors. Each direct-buried single conductor cable shall be located in close proximity in the trench to the other single conductor cables in the same parallel set of conductors in the circuit, including equipment grounding conductors.

Exception No. 2: Isolated phase, polarity, grounded conductor, and equipment grounding and bonding conductor installations shall be permitted in nonmetallic raceways or cables with a nonmetallic covering or nonmagnetic sheath in close proximity where conductors are paralleled as permitted in 310.10(G), and where the conditions of 300.20(B) are met.

(J) Earth Movement.

300.6 Protection Against Corrosion and Deterioration.

Raceways, cable trays, cablebus, auxiliary gutters, cable armor, boxes, cable sheathing, cabinets, enclosures (other than surrounding fences and walls), elbows, couplings, fittings, supports, and support hardware shall be of materials suitable for the environment in which they are to be installed.

(A) Ferrous Metal Equipment.

Ferrous metal raceways, cable trays, cablebus, auxiliary gutters, cable armor, boxes, cable sheathing, cabinets, enclosures (other than surrounding fences and walls), elbows, couplings, nipples, fittings, supports, and support hardware shall be suitably protected against corrosion inside and outside (except threads at joints) by a coating of approved corrosion-resistant material. Where corrosion protection is necessary and the conduit is threaded anywhere other than at the factory where the product is listed, the threads shall be coated with an approved electrically conductive, corrosion-resistant compound.

Exception: Stainless steel shall not be required to have protective coatings.

(1) Protected From Corrosion Solely by Enamel.

Where protected from corrosion solely by enamel, ferrous metal raceways, cable trays, cablebus, auxiliary gutters, cable armor, boxes, cable sheathing, cabinets, enclosures (other than surrounding fences and walls), elbows, couplings, nipples, fittings, supports, and support hardware shall not be used outdoors or in wet locations as described in 300.6(D).

(2) Organic Coatings on Boxes or Cabinets.

Where boxes, cabinets, or enclosures (other than surrounding fences and walls) have an approved system of organic coatings and are marked "Raintight," "Rainproof," or "Outdoor Type," they shall be permitted outdoors.

(3) In Concrete or in Direct Contact With the Earth.

Ferrous metal raceways, cable armor, boxes, cable sheathing, cabinets, enclosures (other than surrounding fences and walls), elbows, couplings, nipples, fittings, supports, and support hardware shall be permitted to be installed in concrete, in direct contact with the earth, or in areas subject to severe corrosive influences where made of material approved for the condition or where provided with corrosion protection approved for the condition.

(B) Aluminum Metal Equipment.

Aluminum raceways, cable trays, cablebus, auxiliary gutters, cable armor, boxes, cable sheathing, cabinets, enclosures (other than surrounding fences and walls), elbows, couplings, nipples, fittings, supports, and support hardware embedded or encased in concrete or in direct contact with the earth shall be provided with supplementary corrosion protection.

(C) Nonmetallic Equipment.

Nonmetallic raceways, cable trays, cablebus, auxiliary gutters, boxes, cables with a nonmetallic outer jacket and internal metal armor or jacket, cable sheathing, cabinets, enclosures (other than surrounding fences and walls), elbows, couplings, nipples, fittings, supports, and support hardware shall be made of material approved for the condition and shall comply with 300.6(C)(1) and (C)(2) as applicable to the specific installation.

(1) Exposed to Sunlight.

Where exposed to sunlight, the materials shall be listed as sunlight resistant or shall be identified as sunlight resistant.

(2) Chemical Exposure.

Where subject to exposure to chemical solvents, vapors, splashing, or immersion, materials or coatings shall either be inherently resistant to chemicals based on their listing or be identified for the specific chemical reagent.

(D) Indoor Wet Locations.

In portions of dairy processing facilities, laundries, canneries, and other indoor wet locations, and in locations where walls are frequently washed or where there are surfaces of absorbent materials, such as damp paper or wood, the entire wiring system, where installed exposed, including all boxes, cabinets, enclosures (other than surrounding fences and walls), fittings, raceways, and cable used therewith, shall be mounted so that there is at least a 6 mm (1/4 in.) airspace between it and the wall or supporting surface.

Exception: Nonmetallic raceways, boxes, and fittings shall be permitted to be installed without the airspace on a concrete, masonry, tile, or similar surface.

Informational Note: In general, areas where acids and alkali chemicals are handled and stored might present such corrosive conditions, particularly when wet or damp. Severe corrosive conditions might also be present in portions of meatpacking plants, tanneries, glue houses, and some stables; in installations immediately adjacent to a seashore and swimming pool areas; in areas where chemical deicers are used; and in storage cellars or rooms for hides, casings, fertilizer, salt, and bulk chemicals.

300.7 Raceways Exposed to Different Temperatures.

(A) Sealing.

Where portions of a raceway or sleeve are known to be subjected to different temperatures, and where condensation is known to be a problem, as in cold storage areas of buildings or where passing from the interior to the exterior of a building, the raceway or sleeve shall be sealed to prevent the circulation of warm air to a colder section of the raceway or sleeve. Sealants shall be identified for use with cable insulation, conductor insulation, a bare conductor, a shield, or other components. An explosionproof seal shall not be required for this purpose.

(B) Expansion, Expansion-Deflection, and Deflection Fittings.

Raceways shall be provided with expansion, expansion-deflection, or deflection fittings where necessary to compensate for thermal expansion, deflection, and contraction.

Informational Note No. 1: Table 352.44(A) and Table 355.44 provide the expansion information for polyvinyl chloride (PVC) and for reinforced thermosetting resin conduit (RTRC), respectively. A nominal number for steel conduit can be determined by multiplying the expansion length in Table 352.44(A) by 0.20. The coefficient of expansion for steel electrical metallic tubing, intermediate metal conduit, and rigid metal conduit is 1.170 × 10-5 (0.0000117) mm per mm of conduit for each °C in temperature change) [0.650 × 10-5 (0.0000065 in. per in. of conduit for each °F in temperature change)].

A nominal number for aluminum conduit and aluminum electrical metallic tubing can be determined by multiplying the expansion length in Table 352.44(A) by 0.40. The coefficient of expansion for aluminum electrical metallic tubing and aluminum rigid metal conduit is 2.34 × 10-5 (0.0000234 mm per mm of conduit for each °C in temperature change) [1.30 × 10-5 (0.000013 in. per in. of conduit for each °F in temperature change)].

300.10 Electrical Continuity of Metal Raceways, Cable Armor, and Enclosures.

Metal raceways, cable armor, and other metal enclosures for conductors shall be metallically joined together into a continuous electrical conductor and shall be connected to all boxes, fittings, and cabinets to provide effective electrical continuity. Unless specifically permitted elsewhere in this Code, raceways and cable assemblies shall be mechanically secured to boxes, fittings, cabinets, and other enclosures.

Exception No. 1: Short sections of raceways used to provide support or protection of cable assemblies from physical damage shall not be required to be made electrically continuous.

Exception No. 2: Equipment enclosures to be isolated, as permitted by 250.96(B), shall not be required to be metallically joined to the metal raceway.

300.11 Securing and Supporting.

(B) Wiring Systems Installed Above Suspended Ceilings.

Support wires that do not provide secure support shall not be the sole support. Support wires and associated fittings that provide secure support and that are installed in addition to the ceiling grid support wires shall be permitted as the sole support. Where independent support wires are used, they shall be secured at both ends. Cables and raceways shall not be supported by ceiling grids.

(1) Fire-Rated Assemblies.

Wiring located within the cavity of a fire-rated floor-ceiling or roof-ceiling assembly shall not be secured to, or supported by, the ceiling assembly, including the ceiling support wires. An independent means of secure support shall be provided and shall be permitted to be attached to the assembly. Where independent support wires are used, they shall be distinguishable by color, tagging, or other effective means from those that are part of the fire-rated design.

Exception: The ceiling support system shall be permitted to support wiring and equipment that have been tested as part of the fire-rated assembly.

Informational Note: See ASTM E119, Standard Test Methods for Fire Tests of Building Construction and Materials, for one method of testing to determine fire rating.

(2) Non-Fire-Rated Assemblies.

Wiring located within the cavity of a non-fire-rated floor-ceiling or roof-ceiling assembly shall not be secured to, or supported by, the ceiling assembly, including the ceiling support wires. An independent means of secure support shall be provided and shall be permitted to be attached to the assembly. Where independent support wires are used, they shall be distinguishable by color, tagging, or other effective means.

Exception: The ceiling support system shall be permitted to support branch-circuit wiring and associated equipment where installed in accordance with the ceiling system manufacturer's instructions.

(C) Raceways Used as Means of Support.

Raceways shall be used only as a means of support for other raceways, cables, or nonelectrical equipment under any of the following conditions:

- Where the raceway or means of support is identified as a means of support

- Where the raceway contains power supply conductors for electrically controlled equipment and is used to support Class 2 or Class 3 circuit conductors or cables that are solely for the purpose of connection to the equipment control circuits

- Where the raceway is used to support boxes or conduit bodies in accordance with 314.23 or to support luminaires in accordance with 410.36(E)

300.12 Mechanical Continuity - Raceways and Cables.

Raceways, cable armors, and cable sheaths shall be continuous between cabinets, boxes, conduit bodies, fittings, or other enclosures or outlets.

Exception No. 1: Short sections of raceways used to provide support or protection of cable assemblies from physical damage shall not be required to be mechanically continuous.

Exception No. 2: Raceways and cables installed into the bottom of open bottom equipment, such as switchboards, motor control centers, and floor or pad-mounted transformers, shall not be required to be mechanically secured to the equipment.

300.13 Mechanical and Electrical Continuity - Conductors.

(B) Device Removal.

In multiwire branch circuits, the continuity of a grounded conductor shall not depend on device connections such as lampholders, receptacles, and so forth where the removal of such devices would interrupt the continuity.

300.14 Length of Free Conductors at Outlets, Junctions, and Switch Points.

At least 150 mm (6 in.) of free conductor, measured from the point in the box where it emerges from its raceway or cable sheath, shall be left at each outlet, junction, and switch point for splices or the connection of luminaires or devices. The 150 mm (6 in.) free conductor shall be permitted to be spliced or unspliced. Where the opening to an outlet, junction, or switch point is less than 200 mm (8 in.) in any dimension, each conductor shall be long enough to extend at least 75 mm (3 in.) outside the opening.

Exception: Conductors that are not spliced or terminated at the outlet, junction, or switch point shall not be required to comply with 300.14.

300.15 Boxes, Conduit Bodies, or Fittings - Where Required.

A box shall be installed at each outlet and switch point for concealed knob-and-tube wiring.

Fittings and connectors shall be used only with the specific wiring methods for which they are designed and listed.

Where the wiring method is conduit, tubing, Type AC cable, Type MC cable, Type MI cable, nonmetallic-sheathed cable, or other cables, a box or conduit body shall be installed at each outlet point, switch point, conductor splice point, conductor junction point, conductor termination point, wiring method transition point, or conductor pull point, unless otherwise permitted in 300.15(A) through (L).

(A) Wiring Methods With Interior Access.

A box or conduit body shall not be required for each splice, junction, switch, pull, termination, or outlet points in wiring methods with removable covers, such as wireways, multioutlet assemblies, auxiliary gutters, and surface raceways. The covers shall be accessible after installation.

(D) Type MI Cable.

A box or conduit body shall not be required where accessible fittings are used for straight-through splices in mineral-insulated metal-sheathed cable.

(E) Integral Enclosure.

A wiring device with integral enclosure identified for the use, having brackets that securely fasten the device to walls or ceilings of conventional on-site frame construction, for use with nonmetallic-sheathed cable, shall be permitted in lieu of a box or conduit body.

(F) Fitting.

A fitting identified for the use shall be permitted in lieu of a box or conduit body where conductors are not spliced or terminated within the fitting. The fitting shall be accessible after installation, unless listed for concealed installation.

(G) Direct-Buried Conductors and Cables.

As permitted in 300.5(E), a box or conduit body shall not be required for splices and taps in direct-buried conductors and cables.

(H) Insulated Devices.

As permitted in 334.40(B), a box or conduit body shall not be required for insulated devices supplied by nonmetallic-sheathed cable.

(I) Enclosures.

A box or conduit body shall not be required where a splice, switch, terminal, or pull point is in a cabinet or cutout box, in an enclosure for a switch or overcurrent device as permitted in 312.8, in a motor controller as permitted in 430.10(A), or in a motor control center.

(J) Luminaires.

A box or conduit body shall not be required where a luminaire is used as a raceway as permitted in 410.64.

(L) Manholes and Handhole Enclosures.

A box or conduit body shall not be required for conductors in manholes or handhole enclosures, except where connecting to electrical equipment. The installation shall comply with Part V of Article 110 for manholes, and 314.30 for handhole enclosures.

300.16 Raceway or Cable to Open or Concealed Wiring.

(A) Box, Conduit Body, or Fitting.

A box, conduit body, or terminal fitting having a separately bushed hole for each conductor shall be used wherever a change is made from conduit, electrical metallic tubing, electrical nonmetallic tubing, nonmetallic-sheathed cable, Type AC cable, Type MC cable, or mineral-insulated, metal-sheathed cable and surface raceway wiring to open wiring or to concealed knob-and-tube wiring. A fitting used for this purpose shall contain no taps or splices and shall not be used at luminaire outlets. A conduit body used for this purpose shall contain no taps or splices unless it complies with 314.16(C)(2).

(B) Bushing.

A bushing shall be permitted in lieu of a box or terminal where the conductors emerge from a raceway and enter or terminate at equipment, such as open switchboards, unenclosed control equipment, or similar equipment. The bushing shall be of the insulating type for other than lead-sheathed conductors.

300.17 Number and Size of Conductors and Cables in Raceway.

The number and size of conductors and cables in any raceway shall not be more than will permit dissipation of the heat and ready installation or withdrawal of the conductors or cables without damage to the conductors or cables, or to their insulation.

Informational Note: See the following sections of this Code. intermediate metal conduit, 342.22; rigid metal conduit, 344.22: flexible metal conduit, 348.22; liquidtight flexible metal conduit, 350.22; PVC conduit, 352.22; HDPE conduit, 353.22; RTRC, 355.22; liquidtight nonmetallic flexible conduit, 356.22; electrical metallic tubing, 358.22; flexible metallic tubing, 360.22; electrical nonmetallic tubing, 362.22; cellular concrete floor raceways, 372.22; cellular metal floor raceways, 374.22: metal wireways, 376.22; nonmetallic wireways, 378.22; surface metal raceways, 386.22; surface nonmetallic raceways, 388.22; underfloor raceways, 390.22; fixture wire, 402.7; theaters, 520.6; signs, 600.31(C); elevators, 620.33; audio signal processing, amplification, and reproduction equipment, 640.23(A) and 640.24; Class 1 circuits, 724.3(A); Class 2, Class 3, Class 4, and power-limited fire alarm (PLFA) circuits, 722.3(A); non-power-limited fire alarm (NPLFA) circuits, 760.3(H); and optical fiber cables and raceways, 770.110(B).

300.18 Raceway Installations.

(A) Complete Runs.

Raceways other than busways, listed manufactured assemblies in accordance with 604.100, or exposed raceways having hinged or removable covers shall be installed complete between outlet, junction, or splicing points prior to the installation of conductors or cables. Where required to facilitate the installation of utilization equipment, the raceway shall be permitted to be initially installed without a terminating connection at the equipment. Prewired raceway assemblies shall be permitted only where specifically permitted in this Code for the applicable wiring method.

300.19 Supporting Conductors in Vertical Raceways.

(A) Spacing Intervals - Maximum.

Conductors in vertical raceways shall be supported if the vertical rise exceeds the values in Table 300.19(A). At least one support method shall be provided for each conductor at the top of the vertical raceway or as close to the top as practical. Intermediate supports shall be provided as necessary to limit supported conductor lengths to not greater than those values specified in Table 300.19(A).

Exception: Steel wire armor cable shall be supported at the top of the riser with a cable support that clamps the steel wire armor. A safety device shall be permitted at the lower end of the riser to hold the cable in the event there is slippage of the cable in the wire-armored cable support. Additional wedge-type supports shall be permitted to relieve the strain on the equipment terminals caused by expansion of the cable under load.

Table 300.19(A) Spacings for Conductor Supports.

| Conductor Size | Support of Conductors in Vertical Raceways | Conductors | |||

|---|---|---|---|---|---|

| Aluminum or Copper-Clad Aluminum | Copper | ||||

| m | ft | m | ft | ||

| 18 AWG through 8 AWG | Not greater than | 30 | 100 | 30 | 100 |

| 6AWG through 1/0 AWG | Not greater than | 60 | 200 | 30 | 100 |

| 2/0 AWG through 4/0 AWG | Not greater than | 55 | 180 | 25 | 80 |

| Over 4/0 AWG through 350 kcmil | Not greater than | 41 | 135 | 18 | 60 |

| Over 350 kcmil through 500 kcmil | Not greater than | 36 | 120 | 15 | 50 |

| Over 500 kcmil through 750 kcmil | Not greater than | 28 | 95 | 12 | 40 |

| Over 750 kcmil | Not greater than | 26 | 85 | 11 | 35 |

(B) Fire-Resistive Cables and Conductors.

Support methods and spacing intervals for fire-resistive cables and conductors shall comply with any restrictions provided in the listing of the electrical circuit protective system or fire-resistive cable system used and in no case shall exceed the values in Table 300.19(A).

(C) Support Methods.

One of the following methods of support shall be used:

- Clamping devices constructed of or employing insulating wedges inserted in the ends of the raceways. Where clamping of insulation does not adequately support the cable, the conductor also shall be clamped.

- Inserting boxes at the required intervals in which insulating supports are installed and secured in an approved manner to withstand the weight of the conductors attached thereto, the boxes being provided with covers.

- In junction boxes, deflecting the cables not less than 90 degrees and carrying them horizontally to a distance not less than twice the diameter of the cable, with the cables being carried on two or more insulating supports and additionally secured thereto by tie wires, if desired. Where this method is used, cables shall be supported at intervals not greater than 20 percent of the support spacing in Table 300.19(A).

- Other approved means.

300.20 Induced Currents in Ferrous Metal Enclosures or Ferrous Metal Raceways.

(A) Conductors Grouped Together.

Where conductors carrying alternating current are installed in ferrous metal enclosures or ferrous metal raceways, they shall be arranged so as to avoid heating the surrounding ferrous metal by induction. To accomplish this, all phase conductors and, where used, the grounded conductor and all equipment grounding conductors shall be grouped together.

Exception No. 1: Equipment grounding conductors for certain existing installations shall be permitted to be installed separate from their associated circuit conductors where run in accordance with 250.130(C).

(B) Individual Conductors.

Where a single conductor carrying alternating current passes through metal with magnetic properties, the inductive effect shall be minimized by either cutting slots in the metal between the individual holes through which the individual conductors pass or passing all the conductors in the circuit through an insulating wall sufficiently large for all of the conductors of the circuit.

Exception: In the case of circuits supplying vacuum or electric-discharge lighting systems or signs or X-ray apparatus, the currents carried by the conductors are so small that the inductive heating effect can be ignored where these conductors are placed in metal enclosures or pass through metal.

Informational Note: Because aluminum is not a magnetic metal, there will be no heating due to hysteresis; however, induced currents will be present. They will not be of sufficient magnitude to require grouping of conductors or special treatment in passing conductors through aluminum wall sections.

300.21 Spread of Fire or Products of Combustion.

Electrical installations in hollow spaces, vertical shafts, and ventilation or air-handling ducts shall be made so that the possible spread of fire or products of combustion will not be substantially increased. Openings around electrical penetrations into or through fire-resistant-rated walls, partitions, floors, or ceilings shall be firestopped using approved methods to maintain the fire resistance rating.

Informational Note: Directories of electrical construction materials published by qualified testing laboratories contain many listing installation restrictions necessary to maintain the fire-resistive rating of assemblies where penetrations or openings are made. Building codes also contain restrictions on membrane penetrations on opposite sides of a fire-resistance-rated wall assembly. An example is the 600-mm (24-in.) minimum horizontal separation that usually applies between boxes installed on opposite sides of the wall. Assistance in complying with the requirements of 300.21 can be found in building codes, fire resistance directories, and product listings.

300.22 Wiring in Ducts Not Used for Air Handling, Fabricated Ducts for Environmental Air, and Other Spaces for Environmental Air (Plenums).

The requirements of this section shall apply to the installation and uses of electrical wiring and equipment in ducts used for dust, loose stock, or vapor removal; ducts specifically fabricated for environmental air; and other spaces used for environmental air (plenums).

Informational Note: See Part VI of Article 424 for requirements on duct heaters.

(A) Ducts for Dust, Loose Stock, or Vapor Removal.

No wiring systems of any type shall be installed in ducts used to transport dust, loose stock, or flammable vapors. No wiring system of any type shall be installed in any duct, or shaft containing only such ducts, used for vapor removal or for ventilation of commercial-type cooking equipment.

(B) Ducts Specifically Fabricated for Environmental Air.

Equipment, devices, and the wiring methods specified in this section shall be permitted within such ducts only if necessary for the direct action upon, or sensing of, the contained air. Where equipment or devices are installed and illumination is necessary to facilitate maintenance and repair, enclosed gasketed-type luminaires shall be permitted.

Only wiring methods consisting of Type MI cable without an overall nonmetallic covering, Type MC cable employing a smooth or corrugated impervious metal sheath without an overall nonmetallic covering, electrical metallic tubing, flexible metallic tubing, intermediate metal conduit, or rigid metal conduit without an overall nonmetallic covering shall be installed in ducts specifically fabricated to transport environmental air. Flexible metal conduit shall be permitted, in lengths not to exceed 1.2 m (4 ft), to connect physically adjustable equipment and devices permitted to be in these fabricated ducts. The connectors used with flexible metal conduit shall effectively close any openings in the connection.

Exception: Wiring methods and cabling systems, listed for use in other spaces used for environmental air (plenums), shall be permitted to be installed in ducts specifically fabricated for environmental air-handling purposes under both of the following conditions:

(1) The wiring methods or cabling systems shall be permitted only if necessary to connect to equipment or devices associated with the direct action upon or sensing of the contained air.

(2) The total length of such wiring methods or cabling systems shall not exceed 1.2 m (4 ft).

(C) Other Spaces Used for Environmental Air (Plenums).

This section shall apply to spaces not specifically fabricated for environmental air-handling purposes but used for air-handling purposes as a plenum. This section shall not apply to habitable rooms or areas of buildings, the prime purpose of which is not air handling.

Informational Note No. 1: The space over a hung ceiling used for environmental air-handling purposes is an example of the type of other space to which this section applies.

Informational Note No. 2: See NFPA 90A, Standard for the Installation of Air-Conditioning and Ventilating Systems, and other mechanical codes for information on how the term other spaces used for environmental air (plenum), as used in this section, correlates with the use of the term plenum where the plenum is used for return air purposes, as well as some other air-handling spaces.

Exception: This section shall not apply to the joist or stud spaces of dwelling units where the wiring passes through such spaces perpendicular to the long dimension of such spaces.

(1) Wiring Methods.

The wiring methods for other spaces used for environmental air shall be limited to totally enclosed, nonventilated, insulated busway having no provisions for plugin connections, Type MI cable without an overall nonmetallic covering, Type MC cable without an overall nonmetallic covering, Type AC cable, or other factory-assembled multiconductor control or power cable that is specifically listed for use within an air-handling space, or listed prefabricated cable assemblies of metallic manufactured wiring systems without nonmetallic sheath. Other types of cables, conductors, and raceways shall be permitted to be installed in electrical metallic tubing, flexible metallic tubing, intermediate metal conduit, rigid metal conduit without an overall nonmetallic covering, flexible metal conduit, or, where accessible, surface metal raceway or metal wireway with metal covers.

Nonmetallic cable ties and other nonmetallic cable accessories used to secure and support cables shall be listed as having low smoke and heat release properties.

Informational Note: See UL 2043, Fire Test for Heat and Visible Smoke Release for Discrete Products and Their Accessories Installed in Air-Handling Spaces, for one method of testing low smoke and heat release properties for nonmetallic cable ties and other nonmetallic cable accessories to determine a maximum peak optical density of 0.50 or less, an average optical density of 0.15 or less, and a peak heat release rate of 100 kW or less.

(2) Cable Tray Systems.

The requirements in 300.22(C)(2)(a) or (C)(2)(b) shall apply to the use of metallic cable tray systems in other spaces used for environmental air (plenums), where accessible.

- Metal Cable Tray Systems. Metal cable tray systems shall be permitted to support the wiring methods specified in 300.22(C)(1).

- Solid Side and Bottom Metal Cable. Tray Systems. Solid side and bottom metal cable tray systems with solid metal covers shall be permitted to enclose wiring methods and cables not already covered in 300.22(C)(1) in accordance with 392.10(A) and (B).

(3) Equipment.

Electrical equipment with a metal enclosure, or electrical equipment with a nonmetallic enclosure listed for use within an air-handling space and having low smoke and heat release properties, and associated wiring material suitable for the ambient temperature shall be permitted to be installed in such other spaces unless prohibited elsewhere in this Code.

Informational Note: See UL 2043, Fire Test for Heat and Visible Smoke Release for Discrete Products and Their Accessories Installed in Air-Handling Spaces, for one method of testing low smoke and heat release properties to determine that the equipment exhibits a maximum peak optical density of 0.50 or less, an average optical density of 0.15 or less, and a peak heat release rate of 100 kW or less.

Exception: Integral fan systems shall be permitted where specifically identified for use within an air-handling space.

(D) Information Technology Equipment.

Where the installation complies with the special requirements specified in 645.4, electrical wiring in air-handling areas beneath raised floors for information technology equipment shall be permitted in accordance with 645.5(E).

300.25 Exit Enclosures (Stair Towers).

Where an exit enclosure is required to have a fire resistance rating, only electrical wiring methods serving equipment permitted by the authority having jurisdiction in the exit enclosure shall be installed within the exit enclosure.

Exception: Where egress lighting is required on outside exterior doorways from the exit enclosure, luminaires shall be permitted to be supplied from the inside of the exit enclosure.

Informational Note: See NFPA 101-2021, Life Safety Code, 7.1.3.2.1 (10)(b), for more information.

300.26 Remote-Control and Signaling Circuits Classification.

Remote-control and signaling circuits shall be classified as either power-limited or non-power-limited and comply with the following:

- Class 1 power-limited remote-control and signaling circuits shall comply with 724.3.

- Class 2 and Class 3 power-limited remote-control and signaling circuits shall comply with 725.3.

- Non-power-limited remote-control and signaling circuits shall be installed in accordance with 300.2 through 300.25.

Article 305

General Requirements for Wiring Methods and Materials for Systems Rated Over 1000 Volts AC, 1500 Volts DC, Nominal

305.1 Scope.

This article covers wiring methods and materials for systems rated over 1000 volts ac, 1500 volts dc, nominal.

305.3 Other Articles.

Conductors shall be permitted to be installed in accordance with any of the wiring methods identified in Table 305.3.

Exposed runs of Type MV cables, bare conductors, and bare busbars shall be permitted in locations accessible only to qualified persons. Busbars shall be permitted to be either copper or aluminum.

Exception: Airfield lighting cable used in series circuits that are powered by regulators and installed in restricted airport lighting vaults shall be permitted as exposed cable installations.

Informational Note: An example of a common application is FAA L-824 cables installed as exposed runs within a restricted vault area.

Table 305.3 Wiring Methods Permitted for Use in Systems Rated Over 1000 Volts ac, 1500 Volts dc, Nominal.

| Wiring Methods Permitted for Use Above 1000 Volts ac, 1500 Volts dc | Voltage Levels | Reference |

|---|---|---|

| Pull and junction boxes, conduit bodies, and handhole enclosures | Over 1000 | Article 314, Part IV |

| Metal-clad cable (Type MC) | 1000—35,000 | Article 330 |

| Type P cable | 1000—2000 | Article 337 |

| Intermediate metal conduit (IMC) | Over 1000 | Article 342 |

| Rigid metal conduit (RMC) | Over 1000 | Article 344 |

| Rigid polyvinyl chloride conduit (PVC) | Over 1000 | Article 352 |

| Reinforced thermosetting resin conduit (RTRC) | Over 1000 | Article 355 |

| Electrical metallic tubing (EMT) | Over 1000 | Article 358 |

| Auxiliary gutters | Over 1000 | Article 366 |

| Busway | Over 1000 | Article 368, Part IV |

| Cablebus | 1000—35,000 | Article 370 |

| Cable trays | 1000—35,000 | Article 392 |

| Messenger-supported wiring | 1000—35,000 | Article 396 |

| Outdoor overhead conductors | Over 1000 | Article 395 |

| Insulated bus pipe (IBP) | 1000—35,000 ac | Article 369 |

305.4 Conductors of Different Systems.

Conductors of circuits rated over 1000 volts ac, 1500 volts dc, nominal, shall not occupy the same equipment wiring enclosure, cable, or raceway with conductors of circuits rated 1000 volts ac, 1500 volts dc, nominal, or less unless otherwise permitted as follows:

- Where contained within the individual wiring enclosure, primary leads of electric-discharge lamp ballasts insulated for the primary voltage of the ballast shall be permitted to occupy the same luminaire, sign, or outline lighting enclosure as the branch-circuit conductors.

- Excitation, control, relay, and ammeter conductors used in connection with any individual motor or starter shall be permitted to occupy the same enclosure as the motor-circuit conductors.

- Conductors of different voltage ratings shall be permitted in motors, transformers, switchgear, switchboards, control assemblies, and similar equipment.

- If the conductors of each system in a manhole are permanently and effectively separated from the conductors of the other systems and securely fastened to racks, insulators, or other approved supports, conductors of different voltage ratings shall be permitted.

305.5 Conductor Bending Radius.

The conductor shall not be bent to a radius less than 8 times the overall diameter for nonshielded conductors or 12 times the overall diameter for shielded or lead-covered conductors during or after installation. For multiconductor or multiplexed single-conductor cables having individually shielded conductors, the minimum bending radius shall be 12 times the diameter of the individually shielded conductors or 7 times the overall diameter, whichever is greater.

305.7 Covers Required.

Suitable covers shall be installed on all boxes, fittings, and similar enclosures to prevent accidental contact with energized parts or physical damage to parts or insulation.

305.8 Raceways in Wet Locations Above Grade.

Where raceways are installed in wet locations above grade, the interior of these raceways shall be considered to be a wet location. Insulated conductors and cables installed in raceways in wet locations above grade shall be either moisture-impervious metal-sheathed or of a type listed for use in wet locations.

305.9 Braid-Covered Insulated Conductors - Exposed Installation.

Exposed runs of braid-covered insulated conductors shall have a flame-retardant braid. If the conductors used do not have this protection, a flame-retardant saturant shall be applied to the braid covering after installation. This treated braid covering shall be stripped back a safe distance at conductor terminals, according to the operating voltage. Where practicable, this distance shall not be less than 25 mm (1 in.) for each kilovolt of the conductor-to-ground voltage of the circuit.

305.10 Insulation Shielding.

Metallic and semiconducting insulation shielding components of shielded cables shall be removed for a distance dependent on the circuit voltage and insulation. Stress reduction means shall be provided at all terminations of factory-applied shielding.

Metallic shielding components such as tapes, wires, or braids, or combinations of them, shall be connected to an equipment grounding conductor, an equipment grounding busbar, or a grounding electrode.

305.11 Moisture or Mechanical Protection for Metal-Sheathed Cables.

Where cable conductors emerge from a metal sheath and where protection against moisture or physical damage is necessary, the insulation of the conductors shall be protected by a cable sheath terminating device.

305.15 Underground Installations.

(A) General.

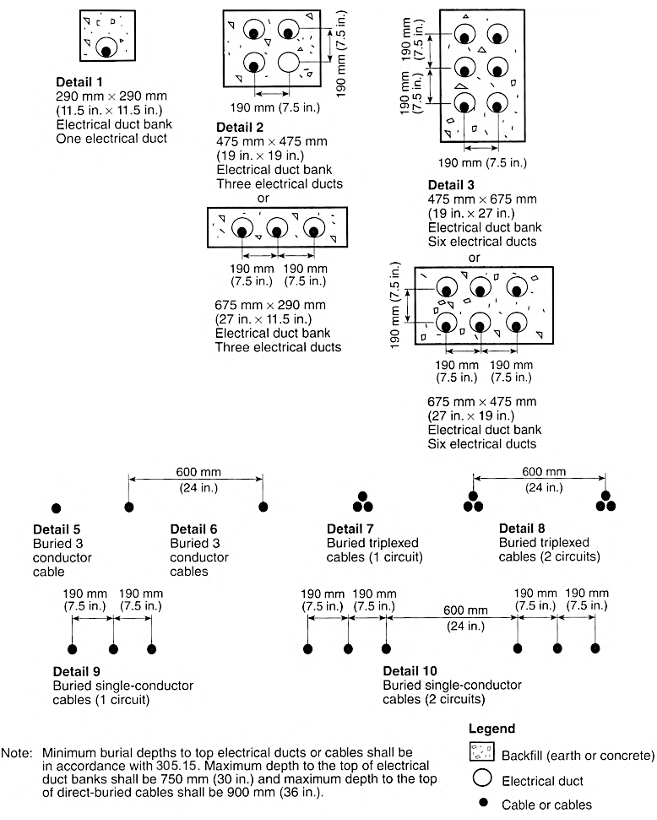

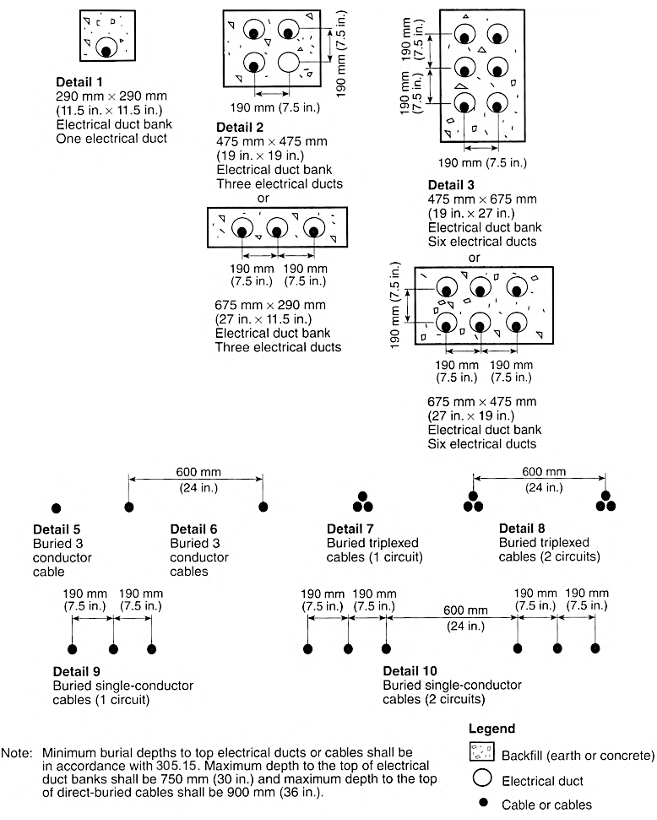

Underground conductors shall be identified for the voltage and conditions under which they are installed. Conductors used for direct-burial applications shall be of a type identified for such use. Underground cables shall be installed in accordance with 305.15(A)(1), (A)(2), or (A)(3), and the installation shall meet the depth requirements of Table 305.15(A).

Table 305.15(A) Minimum Cover Requirements.

| Circuit Voltage | General Conditions (not otherwise specified) | Special Conditions (use if applicable) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Column 1 | Column 2 | Column 3 | Column 4 | Column 5 | Column 6 | |||||||

| Direct-Buried Cables1 | Electrical Metallic Tubing, RTRC, PVC, and HDPE Conduit2 | Rigid Metal Conduit and Intermediate Metal Conduit | Raceways Under Buildings or Exterior Concrete Slabs, 100 mm (4 in.) Minimum Thickness3 | Cables in Airport Runways or Adjacent Areas Where Trespass Is Prohibited | Areas Subject to Vehicular Traffic, Such as Thoroughfares and Commercial Parking Areas | |||||||

| mm | in. | mm | in. | mm | in. | mm | in. | mm | in. | mm | in. | |

| Over 1000 V ac, 1500 V dc, through 22 kV | 750 | 30 | 450 | 18 | 150 | 6 | 100 | 4 | 450 | 18 | 600 | 24 |

| Over 22 kV through 40 kV | 900 | 36 | 600 | 24 | 150 | 6 | 100 | 4 | 450 | 18 | 600 | 24 |

| Over 40 kV | 1000 | 42 | 750 | 30 | 150 | 6 | 100 | 4 | 450 | 18 | 600 | 24 |

Notes:

- Cover shall be defined as the shortest distance in millimeters (inches) measured between a point on the top surface of any direct-buried conductor, cable, conduit, or other raceway and the top surface of finished grade, concrete, or similar cover.

- Lesser depths shall be permitted where cables and conductors rise for terminations or splices or where access is otherwise required.

- Where solid rock prevents compliance with the cover depths specified in this table, the wiring shall be installed in a metal or nonmetallic raceway permitted for direct burial. The raceways shall be covered by a minimum of 50 mm (2 in.) of concrete extending down to rock.

- In industrial establishments, where conditions of maintenance and supervision ensure that qualified persons will service the installation, the minimum cover requirements for other than rigid metal conduit and intermediate metal conduit shall be permitted to be reduced 150 mm (6 in.) for each 50 mm (2 in.) of concrete or equivalent placed entirely within the trench over the underground installation.

1Underground direct-buried cables that are not encased or protected by concrete and are buried 750 mm (30 in.) or more below grade shall have their location identified by a warning ribbon that is placed in the trench at least 300 mm (12 in.) above the cables.

2Listed by a qualified testing agency as suitable for direct burial without encasement. All other nonmetallic systems shall require 50 mm (2 in.) of concrete or equivalent above conduit in addition to the table depth.

3The slab shall extend a minimum of 150 mm (6 in.) beyond the underground installation, and a warning ribbon or other effective means suitable for the conditions shall be placed above the underground installation.

(1) Shielded Cables and Nonshielded Cables in Metal-Sheathed Cable Assemblies.

Underground cables, including nonshielded, Type MC and moisture-impervious metal sheath cables, shall have those sheaths grounded through an effective grounding path meeting the requirements of 250.4(A)(5) or 250.4(B)(4). They shall be direct buried or installed in raceways identified for the use.

(3) Other Nonshielded Cables.

Other nonshielded cables not covered in 305.15(A)(1) or (A)(2) shall be installed in rigid metal conduit, intermediate metal conduit, or rigid nonmetallic conduit encased in not less than 75 mm (3 in.) of concrete.

(B) Wet Locations.

The interior of enclosures or raceways installed underground shall be considered to be a wet location. Insulated conductors and cables installed in these enclosures or raceways in underground installations shall be listed for use in wet locations and shall be either moisture-impervious metal-sheathed or of a type listed for use in wet locations. Any connections or splices in an underground installation shall be approved for wet locations.

(C) Protection From Damage.

Conductors emerging from the ground shall be enclosed in listed raceways. Raceways installed on poles shall be of rigid metal conduit, intermediate metal conduit, RTRC-XW, Schedule 80 PVC conduit, or equivalent, extending from the minimum cover depth specified in Table 305.15(A) to a point 2.5 m (8 ft) above finished grade. Conductors entering a building shall be protected by an approved enclosure or raceway from the minimum cover depth to the point of entrance. Where direct-buried conductors, raceways, or cables are subject to movement by settlement or frost, they shall be installed to prevent damage to the enclosed conductors or to the equipment connected to the raceways. Metallic enclosures shall be grounded.

(D) Splices.

Direct burial cables shall be permitted to be spliced or tapped without the use of splice boxes if they are installed using materials suitable for the application. The taps and splices shall be watertight and protected from mechanical damage. Where cables are shielded, the shielding shall be continuous across the splice or tap.

Exception: At splices of an engineered cabling system, metallic shields of direct-buried single-conductor cables with maintained spacing between phases shall be permitted to be interrupted and overlapped. Where shields are interrupted and overlapped, each shield section shall be grounded at one point.

(E) Backfill.

Backfill containing large rocks, paving materials, cinders, large or sharply angular substances, or corrosive materials shall not be placed in an excavation where materials can damage or contribute to the corrosion of raceways, cables, or other substructures or where it might prevent adequate compaction of fill.

(F) Raceway Seal.

Where a raceway enters from an underground system, the end within the building shall be sealed with an identified compound to prevent the entrance of moisture.

Informational Note: Presence of hazardous gases or vapors might also necessitate sealing of underground conduits or raceways entering buildings.

Article 310

Conductors for General Wiring

310.1 Scope.

This article covers general requirements for conductors rated up to and including 2000 volts and their type designations, insulations, markings, mechanical strengths, ampacity ratings, and uses. These requirements do not apply to conductors that form an integral part of equipment, such as motors, motor controllers, and similar equipment, or to conductors specifically provided for elsewhere in this Code.

310.3 Conductors.

(A) Minimum Size of Conductors.

The minimum size of conductors for voltage ratings up to and including 2000 volts shall be 14 AWG copper or 12 AWG aluminum or copper-clad aluminum, except as permitted elsewhere in this Code.

(B) Conductor Material.

Conductors in this article shall be of copper, aluminum, or copper-clad aluminum, unless otherwise specified. Aluminum and copper-clad aluminum shall comply with the following:

- Solid aluminum conductors 8, 10, and 12 AWG shall be made of an AA-8000 series electrical grade aluminum alloy conductor material.

- Stranded aluminum conductors 8 AWG through 1000 kcmil marked as Type RHH. RHW, XHHW, XHHN, XHWN, THW, THHW, THWN, THHN, service-entrance Type SE Style U, and SE Style R shall be made of an AA-8000 series electrical grade aluminum alloy conductor material.

- For copper-clad aluminum conductors, the copper shall form a minimum 10 percent of the cross-sectional area of a solid conductor or each strand of a stranded conductor. The aluminum core of a copper-clad aluminum conductor shall be made of an AA-8000 series electrical grade aluminum alloy conductor material.

- Copper-clad aluminum conductor material shall be listed.

(C) Stranded Conductors.

Where installed in raceways, conductors 8 AWG and larger shall be stranded, unless specifically permitted or required elsewhere in this Code to be solid.

(D) Insulated.

Conductors not specifically permitted elsewhere in this Code to be covered or bare shall be insulated.

Informational Note: See 250.184 for insulation of neutral conductors of a solidly grounded high-voltage system.

310.4 Conductor Constructions and Applications.

Insulated conductors shall comply with Table 310.4(1) and Table 310.4(2).

Informational Note: Thermoplastic insulation may stiffen at temperatures lower than —10°C (+14°F). Thermoplastic insulation may also be deformed at normal temperatures where subjected to pressure, such as at points of support.

Table 310.4(1) Conductor Applications and Insulations Rated 600 Volts.

| Trade Name | Type Letter | Maximum Operating Temperature | Application Provisions | Insulation | Thickness of Insulation | Outer Covering1 | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| AWG or kcmil | mm | mils | ||||||||

| Fluorinated ethylene propylene | FEP or FEPB | 90°C (194°F) |

Dry and damp locations | Fluorinated ethylene propylene | 14—10 | 0.51 | 20 | None | ||

| 8—2 | 0.76 | 30 | ||||||||

| 200°C (392°F) |

Dry locations - special applications2 | Fluorinated ethylene propylene | 14—8 | 0.36 | 14 | Glass braid | ||||

| 6—2 | 0.36 | 14 | Glass or other suitable braid material | |||||||

| Mineral insulation (metal sheathed) | MI | 90°C (194°F) |

Dry and wet locations | Magnesium oxide | 18—163 | 0.58 | 23 | Copper or alloy steel | ||

| 16—10 | 0.91 | 36 | ||||||||

| 250°C (482°F) |

For special applications2 | 9—4 | 1.27 | 50 | ||||||

| 3—500 | 1.40 | 55 | ||||||||

| Moisture-, heat-, and oil-resistant thermoplastic | MTW | 60°C (140°F) |

Machine tool wiring in wet locations | Flame-retardant, moisture-, heat-, and oil-resistant thermoplastic | (A) | (B) | (A) | (B) | (A) None | |

| (B) Nylon jacket or equivalent | ||||||||||

| 90°C (194°F) |

Machine tool wiring in dry locations. | 22—12 | 0.76 | 0.38 | 30 | 15 | ||||

| 10 | 0.76 | 0.51 | 30 | 20 | ||||||

| 8 | 1.14 | 0.76 | 45 | 30 | ||||||

| Informational Note: See NFPA 79-2021. Electrical Standard for Industrial Machinery. |

6 | 1.52 | 0.76 | 60 | 30 | |||||

| 4—2 | 1.52 | 1.02 | 60 | 40 | ||||||

| 1—4/0 | 2.03 | 1.27 | 80 | 50 | ||||||

| 213—500 | 2.41 | 1.52 | 95 | 60 | ||||||

| 501—1000 | 2.79 | 1.78 | 110 | 70 | ||||||

| Paper | 85°C (185°F) |

For underground service conductors, or by special permission | Paper | Lead sheath | ||||||

| Perfluoro-alkoxy | PFA | 90°C (194°F) |

Dry and damp locations | Perfluoro-alkoxy | 14—10 | 0.51 | 20 | None | ||

| 8—2 | 0.76 | 30 | ||||||||

| 200°C (392°F) |

Dry locations - special applications2 | 1—4/0 | 1.14 | 45 | ||||||

| Perfluoro-alkoxy | PFAH | 250°C (482°F) |

Dry locations only. Only for leads within apparatus or within raceways connected to apparatus (nickel or nickel-coated copper only) | Perfluoro-alkoxy | 14—10 | 0.51 | 20 | None | ||

| 8—2 | 0.76 | 30 | ||||||||

| 1—4/0 | 1.14 | 45 | ||||||||

| Thermoset | RHH | 90°C (194°F) |

Dry and damp locations | 14—10 | 1.14 | 45 | Moisture-resistant, flame-retardant, nonmetallic covering1 | |||

| 8—2 | 1.52 | 60 | ||||||||

| 1—4/0 | 2.03 | 80 | ||||||||

| 213—500 | 2.41 | 95 | ||||||||

| 501—1000 | 2.79 | 110 | ||||||||

| 1001—2000 | 3.18 | 125 | ||||||||

| Moisture-resistant thermoset | RHW | 75°C (167°F) |

Dry and wet locations | Flame-retardant, moisture-resistant thermoset | 14—10 | 1.14 | 45 | Moisture-resistant, flame-retardant, nonmetallic covering | ||

| 8—2 | 1.52 | 60 | ||||||||

| 1—4/0 | 2.03 | 80 | ||||||||

| RHW-2 | 90°C (194°F) |

213—500 | 2.41 | 95 | ||||||

| 501—1000 | 2.79 | 110 | ||||||||

| 1001—2000 | 3.18 | 125 | ||||||||

| Silicone | SA | 90°C (194°F) |

Dry and damp locations | Silicone rubber | 14—10 | 1.14 | 45 | Glass or other suitable braid material | ||

| 8—2 | 1.52 | 60 | ||||||||

| 1—4/0 | 2.03 | 80 | ||||||||

| 200°C (392°F) |

For special application2 | 213—500 | 2.41 | 95 | ||||||

| 501—1000 | 2.79 | 110 | ||||||||

| 1001—2000 | 3.18 | 125 | ||||||||

| Thermoset | SIS | 90°C (194°F) |

Switchboard and switchgear wiring only | Flame-retardant thermoset | 14—10 | 0.76 | 30 | None | ||

| 8—2 | 1.14 | 45 | ||||||||

| 1—4/0 | 1.40 | 55 | ||||||||

| Thermoplastic and fibrous outer braid | TBS | 90°C (194°F) |

Switchboard and switchgear wiring only | Thermoplastic | 14—10 | 0.76 | 30 | Flame-retardant, nonmetallic covering | ||

| 8 | 1.14 | 45 | ||||||||

| 6—2 | 1.52 | 60 | ||||||||

| 1—4/0 | 2.03 | 80 | ||||||||

| Extended polytetra-fluoro-ethylene | TFE | 250°C (482°F) |

Dry locations only. Only for leads within apparatus or within raceways connected to apparatus, or as open wiring (nickel or nickel-coated copper only) | Extruded polytetra-fluoroethylene | 14—10 | 0.51 | 20 | None | ||

| 8—2 | 0.76 | 30 | ||||||||

| 1—4/0 | 1.14 | 45 | ||||||||

| Heat-resistant thermoplastic | THHN | 90°C (194°F) |

Dry and damp locations | Flame-retardant, heat-resistant thermoplastic | 14—12 | 0.38 | 15 | Nylon jacket or equivalent | ||

| 10 | 0.51 | 20 | ||||||||

| 8—6 | 0.76 | 30 | ||||||||

| 4—2 | 1.02 | 40 | ||||||||

| 1—4/0 | 1.27 | 50 | ||||||||

| 250—500 | 1.52 | 60 | ||||||||

| 501—1000 | 1.78 | 70 | ||||||||

| Moisture- and heat-resistant thermoplastic | THHW | 75°C (167°F) |

Wet location | Flame-retardant, moisture- and heat-resistant thermoplastic | 14—10 | 0.76 | 30 | None | ||

| 8 | 1.14 | 45 | ||||||||

| 6—2 | 1.52 | 60 | ||||||||

| 90°C (194°F) |

Dry location | 1—4/0 | 2.03 | 80 | ||||||

| 213—500 | 2.41 | 95 | ||||||||

| 501—1000 | 2.79 | 110 | ||||||||

| 1001—2000 | 3.18 | 125 | ||||||||

| Moisture- and heat-resistant thermoplastic | THW | 75°C (167°F) |

Dry and wet locations | Flame-retardant, moisture- and heat-resistant thermoplastic | 14—10 | 0.76 | 30 | None | ||

| 8 | 1.14 | 45 | ||||||||

| 90°C (194°F) |

Special applications within electric discharge lighting equipment. Limited to 1000 open-circuit volts or less. (Size 14—8 only as permitted in 410.68.) | 6—2 | 1.52 | 60 | ||||||

| 1—4/0 | 2.03 | 80 | ||||||||

| 213—500 | 2.41 | 95 | ||||||||

| 501—1000 | 2.79 | 110 | ||||||||

| 1001—2000 | 3.18 | 125 | ||||||||

| THW-2 | 90°C (194°F) |

Dry and wet locations | ||||||||

| Moisture- and heat-resistant thermoplastic | THWN | 75°C (167°F) |

Dry and wet locations | Flame-retardant, moisture- and heat-resistant thermoplastic | 14—12 | 0.38 | 15 | Nylon jacket or equivalent | ||

| 10 | 0.51 | 20 | ||||||||

| 8—6 | 0.76 | 30 | ||||||||

| 4—2 | 1.02 | 40 | ||||||||

| THWN-2 | 90°C (194°F) |

1—4/0 | 1.27 | 50 | ||||||

| 250—500 | 1.52 | 60 | ||||||||

| 501—1000 | 1.78 | 70 | ||||||||

| Moisture-resistant thermoplastic | TW | 60°C (140°F) |

Dry and wet locations | Flame-retardant, moisture-resistant thermoplastic | 14—10 | 0.76 | 30 | None | ||

| 8 | 1.14 | 45 | ||||||||

| 6—2 | 1.52 | 60 | ||||||||

| 1—4/0 | 2.03 | 80 | ||||||||

| 213—500 | 2.41 | 95 | ||||||||

| 501—1000 | 2.79 | 110 | ||||||||

| 1001—2000 | 3.18 | 125 | ||||||||

| Underground feeder and branch-circuit cable - single conductor (for Type UF cable employing more than one conductor, see Part II of Article 340). | UF | 60°C 140°C |

See Part II of Article 340. | Moisture-resistant | 14—10 | 1.52 | 605 | Integral with insulation | ||

| 8—2 | 2.03 | 805 | ||||||||

| 75°C (167°F)4 |

Moisture- and heat-resistant | 1—4/0 | 2.41 | 955 | ||||||

| Underground service-entrance cable - single conductor (for Type USE cable employing more than one conductor, see Part II of Article 338). | USE | 75°C (167°F)4 |

See Part II of Article 338. | Heat- and moisture-resistant | 14—10 | 1.14 | 45 | Moisture-resistant nonmetallic covering (See 338.2.) | ||

| 8—2 | 1.52 | 60 | ||||||||

| USE-2 | 90°C (194°F) |

Dry and wet locations | 1—4/0 | 2.03 | 80 | |||||

| 213—500 | 2.41 | 956 | ||||||||

| 501—1000 | 2.79 | 110 | ||||||||

| 1001—2000 | 3.18 | 125 | ||||||||

| Thermoset | XHH | 90°C (194°F) |

Dry and damp locations | Flame-retardant thermoset | 14—10 | 0.76 | 30 | None | ||

| 8—2 | 1.14 | 45 | ||||||||

| 1—4/0 | 1.40 | 55 | ||||||||

| 213—500 | 1.65 | 65 | ||||||||

| 501—1000 | 2.03 | 80 | ||||||||

| 1001—2000 | 2.41 | 95 | ||||||||

| Thermoset | XHHN | 90°C (194°F) |

Dry and damp locations | Flame-retardant thermoset | 14—12 | 0.38 | 15 | Nylon jacket or equivalent | ||

| 10 | 0.51 | 20 | ||||||||

| 8—6 | 0.76 | 30 | ||||||||

| 4—2 | 1.02 | 40 | ||||||||

| 1—4/0 | 1.27 | 50 | ||||||||

| 250—500 | 1.52 | 60 | ||||||||

| 501—1000 | 1.78 | 70 | ||||||||

| Moisture-resistant thermoset | XHHW | 90°C (194°F) |

Dry and damp locations | Flame-retardant, moisture-resistant thermoset | 14—10 | 0.76 | 30 | None | ||

| 8—2 | 1.14 | 45 | ||||||||

| 75°C (167°F) |

Wet locations | 1—4/0 | 1.40 | 55 | ||||||

| 213—500 | 1.65 | 65 | ||||||||

| 501—1000 | 2.03 | 80 | ||||||||

| 1001—2000 | 2.41 | 95 | ||||||||

| Moisture-resistant thermoset | XHHW-2 | 90°C (194°F) |

Dry and wet locations | Flame-retardant, moisture-resistant thermoset | 14—10 | 0.76 | 30 | None | ||

| 8—2 | 1.14 | 45 | ||||||||

| 1—4/0 | 1.40 | 55 | ||||||||

| 213—500 | 1.65 | 65 | ||||||||

| 501—1000 | 2.03 | 80 | ||||||||

| 1001—2000 | 2.41 | 95 | ||||||||

| Moisture-resistant thermoset | XHWN | 75°C (167°F) |

Dry and wet locations | Flame-retardant, moisture-resistant thermoset | 14—12 | 0.38 | 15 | Nylon jacket or equivalent | ||

| 10 | 0.51 | 20 | ||||||||

| 8—6 | 0.76 | 30 | ||||||||

| XHWN-2 | 90°C (194°F) |

4—2 | 1.02 | 40 | ||||||

| 1—4/0 | 1.27 | 50 | ||||||||

| 250—500 | 1.52 | 60 | ||||||||

| 501—1000 | 1.78 | 70 | ||||||||

| Modified ethylene tetrafluoro-ethylene | Z | 90°C (194°F) |

Dry and damp locations | Modified ethylene tetrafluoro-ethylene | 14—12 | 0.38 | 15 | None | ||

| 10 | 0.51 | 20 | ||||||||

| 150°C (302°F) |

Dry locations - special applications2 | 8—4 | 0.64 | 25 | ||||||

| 3—1 | 0.89 | 35 | ||||||||

| 1/0—4/0 | 1.14 | 45 | ||||||||

| Modified ethylene tetrafluoro-ethylene | ZW | 75°C (167°F) |

Wet locations | Modified ethylene tetrafluoro-ethylene | 14—10 | 0.76 | 30 | None | ||

| 8—2 | 1.14 | 45 | ||||||||

| 90°C (194°F) |

Dry and damp locations | |||||||||

| 150°C (302°F) |

Dry locations - special applications2 | |||||||||

| ZW-2 | 90°C (194°F) |

Dry and wet locations | ||||||||

Note: Conductors in Table 310.4(1) shall be permitted to be rated up to 1000 volts if listed and marked.

1Outer coverings shall not be required where listed without a covering.

2Higher temperature rated constructions shall be permitted where design conditions require maximum conductor operating temperatures above 90°C (194°F).

3Conductor sizes shall be permitted for signaling circuits permitting 300-volt insulation.

5Type UF insulation thickness shall include the integral jacket.

6Insulation thickness shall be permitted to be 2.03 mm (80 mils) for listed Type USE conductors that have been subjected to special investigations. The nonmetallic covering over individual rubber-covered conductors of aluminum-sheathed cable and of lead-sheathed or multiconductor cable shall not be required to be flame retardant.

Table 310.4(2) Thickness of Insulation for Nonshielded Types RHH and RHW Solid Dielectric Insulated Conductors Rated 2000 Volts.

| Conductor Size (AWG or kcmil) |

Column A1 | Column B2 | ||

|---|---|---|---|---|

| mm | mils | mm | mils | |

| 14—10 | 2.03 | 80 | 1.52 | 60 |

| 8 | 2.03 | 80 | 1.78 | 70 |

| 6—2 | 2.41 | 95 | 1.78 | 70 |

| 1—2/0 | 2.79 | 110 | 2.29 | 90 |

| 3/0—4/0 | 2.79 | 110 | 2.29 | 90 |

| 213—500 | 3.18 | 125 | 2.67 | 105 |

| 501—1000 | 3.56 | 140 | 3.05 | 120 |

| 1001—2000 | 3.56 | 140 | 3.56 | 140 |

1Column A insulations shall be limited to natural, SBR, and butyl rubbers.

2Column B insulations shall be materials such as cross-linked polyethylene, ethylene propylene rubber, and composites thereof.

310.6 Conductor Identification.

(C) Ungrounded Conductors.