Article 700

Emergency Systems

700.1 Scope.

This article applies to the electrical safety of the installation, operation, and maintenance of emergency systems consisting of circuits and equipment intended to supply, distribute, and control electricity for illumination, power, or both, to required facilities when the normal electrical supply or system is interrupted.

Informational Note No. 1: Emergency systems are generally installed in places of assembly where artificial illumination is required for safe exiting and for panic control in buildings subject to occupancy by large numbers of persons, such as hotels, theaters, sports arenas, health care facilities, and similar institutions. Emergency systems may also provide power for such functions as ventilation where essential to maintain life, fire detection and alarm systems, elevators, fire pumps, public safety communications systems, industrial processes where current interruption would produce serious life safety or health hazards, and similar functions.

Informational Note No. 2: See Article 517, Health Care Facilities, for further information regarding wiring and installation of emergency systems in health care facilities.

Informational Note No. 3: See NFPA 99-2018, Health Care Facilities Code, for further information regarding performance and maintenance of emergency systems in health care facilities.

Informational Note No. 4: See NFPA 101-2018, Life Safety Code, for specification of locations where emergency lighting is considered essential to life safety.

Informational Note No. 5: See NFPA 110-2019, Standard for Emergency and Standby Power Systems, and NFPA 111-2019, Standard on Stored Electrical Energy Emergency and Standby Power Systems, for further information regarding performance of emergency and standby power systems. Emergency systems are considered Level 1 systems when applying NFPA 110.

700.3 Tests and Maintenance.

(A) Commissioning Witness Test.

The authority having jurisdiction shall conduct or witness the commissioning of the complete system upon installation and periodically afterward.

Informational Note: See NECA 90, Standard for Commissioning Building Electrical Systems.

(B) Tested Periodically.

Systems shall be tested periodically on a schedule approved by the authority having jurisdiction to ensure the systems are maintained in proper operating condition.

(C) Maintenance.

Emergency system equipment shall be maintained in accordance with manufacturer instructions and industry standards.

(D) Written Record.

A written record shall be kept of such tests and maintenance.

(E) Testing Under Load.

Means for testing all emergency lighting and power systems during maximum anticipated load conditions shall be provided.

Informational Note: See NFPA 110-2019, Standard for Emergency and Standby Power Systems, for information on testing and maintenance of emergency power supply systems (EPSSs).

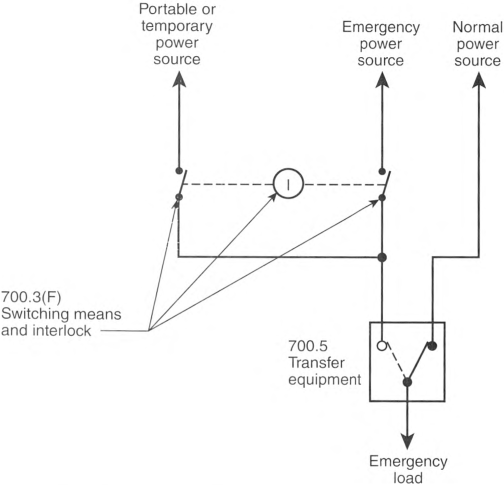

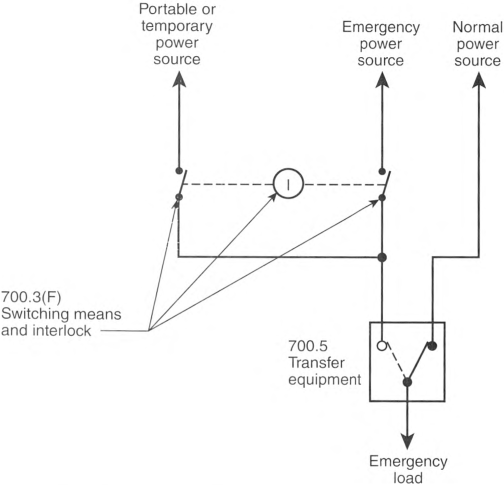

(F) Temporary Source of Power for Maintenance or Repair of the Alternate Source of Power.

If the emergency system relies on a single alternate source of power, which will be disabled for maintenance or repair, the emergency system shall include permanent switching means to connect a portable or temporary alternate source of power that shall be available for the duration of the maintenance or repair. The permanent switching means to connect a portable or temporary alternate source of power shall comply with the following:

- Connection to the portable or temporary alternate source of power shall not require modification of the permanent system wiring.

- Transfer of power between the normal power source and the emergency power source shall be in accordance with 700.12.

- The connection point for the portable or temporary alternate source shall be marked with the phase rotation and system bonding requirements.

- The switching means, including the interlocks, shall be listed and provided with mechanical or mechanical and electrical interlocking to prevent inadvertent interconnection of power sources.

- The switching means shall include a contact point that shall annunciate at a location remote from the generator or at another facility monitoring system to indicate that the permanent emergency source is disconnected from the emergency system.

- The permanent connection point for the temporary generator shall be located outdoors and shall not have cables from the connection point to the temporary generator routed through exterior windows, doors, or similar openings.

- A permanent label shall be field applied at the permanent connection point to identify the system voltage, maximum amperage, short-circuit current rating of the load side of equipment supplied, and ungrounded conductor identification in accordance with 210.5.

It shall be permissible to use manual switching to switch from the permanent source of power to the portable or temporary alternate source of power and to use the switching means for connection of a load bank.

Informational Note: See Informational Note Figure 700.3(F) for one example of many possible methods to achieve the requirements of 700.3(F).

Exception: The permanent switching means to connect a portable or temporary alternate source of power for the duration of the maintenance or repair shall not be required where any of the following conditions exists:

- All processes that rely on the emergency system source are capable of being disabled during maintenance or repair of the emergency source of power.

- The building or structure is unoccupied and fire protection systems are fully functional and do not require an alternate power source.

- Other temporary means can be substituted for the emergency system.

- A permanent alternate emergency source, such as, but not limited to, a second on-site standby generator or separate electric utility service connection, capable of supporting the emergency system, exists.

Informational Note Figure 700.3(F)

700.4 Capacity and Rating.

(A) Capacity.

An emergency system shall have adequate capacity in accordance with Parts I through IV of Article 220 or by another approved method. The system capacity shall be sufficient for the rapid load changes and transient power and energy requirements associated with any expected loads.

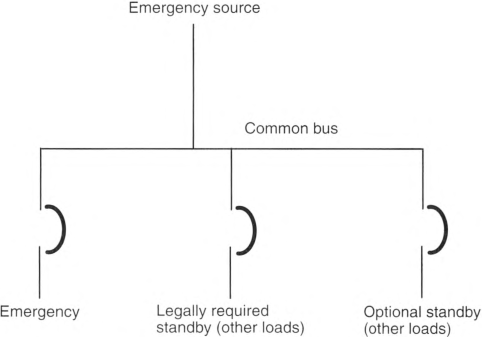

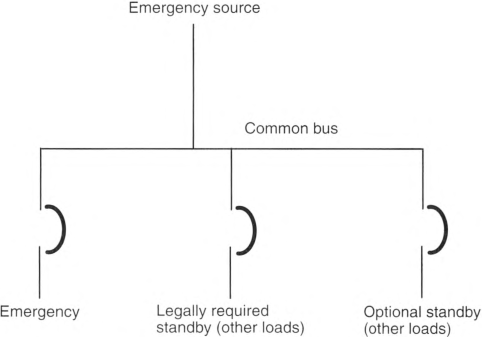

(B) Selective Load Management.

The alternate power source shall be permitted to supply emergency, legally required standby, and optional standby system loads where the source has adequate capacity or where load management (that includes automatic selective load pickup and load shedding) is provided as needed to ensure adequate power to the following in order of priority:

- Emergency circuits

- Legally required standby circuits

- Optional standby circuits

(C) Parallel Operation.

Parallel operation of the emergency source(s) shall consist of the sources specified in 700.4(C)(1) and (C)(2).

(1) Normal Source.

The emergency source shall be permitted to operate in parallel with the normal source in compliance with Part I or Part II of Article 705 where the capacity required to supply the emergency load is maintained at all times. Any operating condition that results in less than the required emergency source capacity shall initiate a system malfunction signal in accordance with 700.6(A).

Parallel operation shall be permitted for satisfying the test requirements of 700.3(B), provided all other conditions of 700.3 are met.

Informational Note: Peak load shaving is one application for parallel source operation.

(2) Emergency Source.

Emergency sources shall be permitted to operate in parallel where the necessary equipment to establish and maintain a synchronous condition is provided.

700.5 Transfer Equipment.

(A) General.

Transfer equipment shall be automatic, listed, and marked for emergency use. Transfer equipment shall be designed and installed to prevent the inadvertent interconnection of normal and emergency sources of supply in any operation of the transfer equipment. Transfer equipment and electric power production systems installed to permit operation in parallel with the normal source shall meet the requirements of Article 705. Meter-mounted transfer switches shall not be permitted for emergency system use.

(B) Bypass Isolation Transfer Switches.

Means shall be permitted to bypass and isolate the transfer equipment. Where bypass isolation transfer switches are used, inadvertent parallel operation shall be prevented.

(D) Redundant Transfer Equipment.

If emergency loads are supplied by a single feeder, the emergency power system shall include redundant transfer equipment or a bypass isolation transfer switch to facilitate maintenance as required in 700.3(C) without jeopardizing continuity of power. If the redundant transfer equipment or bypass isolation transfer switch is manual (or nonautomatic), then it shall be actively supervised by a qualified person when the primary (automatic) transfer equipment is disabled for maintenance or repair.

Exception: The requirement for redundancy with the transfer equipment shall not apply where any of the following conditions exist:

(1) All processes that rely on the emergency system source are capable of being disabled during maintenance or repair activities without jeopardizing the safety to human life.

(2) The building or structure is unoccupied and fire protection systems are fully functional and do not require an alternate power source.

(3) Other temporary means shall be permitted to be substituted for the emergency system.

(4) A written emergency plan that includes mitigation actions and responsibilities for qualified persons to address the recognized site hazards for the duration of the maintenance or repair activities shall be developed and implemented. The emergency plan shall be made available to the authority having jurisdiction.

(F) Documentation.

The short-circuit current rating of the transfer equipment, based on the specific overcurrent protective device type and settings protecting the transfer equipment, shall be field marked on the exterior of the transfer equipment.

700.6 Signals.

Audible, visual, and facility or network remote annunciation devices shall be provided, where applicable, for the purpose described in 700.6(A) through (D).

(A) Malfunction.

Malfunction signals indicate a malfunction of the emergency source.

(B) Carrying Load.

Load carrying signals indicate that the emergency source is carrying load.

(C) Storage Battery Charging Malfunction.

Storage battery charging malfunction signals indicate a charging malfunction on a battery required for source readiness, including starting the prime mover, is not functioning.

(D) Ground Fault.

Ground-fault signals indicate a ground fault in solidly grounded wye emergency systems of more than 150 volts to ground and circuit-protective devices rated 1000 amperes or more. The sensor for the ground-fault signal devices shall be located at, or ahead of, the main system disconnecting means for the emergency source, and the maximum setting of the signal devices shall be for a ground-fault current of 1200 amperes. Instructions on the course of action to be taken in the event of indicated ground fault shall be located at or near the sensor location.

For systems with multiple emergency sources connected to a paralleling bus, the ground fault sensor and the system bonding jumper shall be permitted to be at an alternative location.

700.7 Signs.

(A) Emergency Sources.

A sign shall be placed at the service-entrance equipment, indicating type and location of each on-site emergency power source.

Exception: A sign shall not be required for individual unit equipment as specified in 700.12(H).

(B) Grounding.

Where removal of a grounding or bonding connection in normal power source equipment interrupts the grounding electrode conductor connection to the alternate power source(s) grounded conductor, a warning sign shall be installed at the normal power source equipment stating:

WARNING

SHOCK HAZARD EXISTS IF GROUNDING ELECTRODE CONDUCTOR OR BONDING JUMPER CONNECTION IN THIS EQUIPMENT IS REMOVED WHILE ALTERNATE SOURCE(S) IS ENERGIZED.

SHOCK HAZARD EXISTS IF GROUNDING ELECTRODE CONDUCTOR OR BONDING JUMPER CONNECTION IN THIS EQUIPMENT IS REMOVED WHILE ALTERNATE SOURCE(S) IS ENERGIZED.

The warning sign(s) or label(s) shall comply with 110.21(B).

700.8 Surge Protection.

A listed SPD shall be installed in or on all emergency system switchgear, switchboards, and panelboards.

700.10 Wiring, Emergency System.

(A) Identification.

Emergency circuits shall be permanently marked so they will be readily identified as a component of an emergency circuit or system by the following methods:

- All boxes and enclosures (including transfer switches, generators, and power panels) for emergency circuits shall be permanently marked as a component of an emergency circuit or system.

- Where boxes or enclosures are not encountered, exposed cable or raceway systems shall be permanently marked to be identified as a component of an emergency circuit or system, at intervals not to exceed 7.6 m (25 ft).

Receptacles supplied from the emergency system shall have a distinctive color or marking on the receptacle cover plates or the receptacles.

(B) Wiring.

Wiring from an emergency source or emergency source distribution overcurrent protection to emergency loads shall be kept entirely independent of all other wiring and equipment unless otherwise permitted in the following:

- Wiring from the normal power source located in transfer equipment enclosures

- Wiring supplied from two sources in exit or emergency luminaires

- Wiring from two sources in a listed load control relay supplying exit or emergency luminaires, or in a common junction box, attached to exit or emergency luminaires

- Wiring within a common junction box attached to unit equipment, containing only the branch circuit supplying the unit equipment and the emergency circuit supplied by the unit equipment

- Wiring within a traveling cable to an elevator

- Wiring from an emergency source to supply emergency and other (nonemergency) loads in accordance with the following:

- Separate vertical switchgear sections or separate vertical switchboard sections, with or without a common bus, or individual disconnects mounted in separate enclosures shall be used to separate emergency loads from all other loads.

- The common bus of separate sections of the switchgear, separate sections of the switchboard, or the individual enclosures shall be either of the following:

- Supplied by single or multiple feeders without overcurrent protection at the source

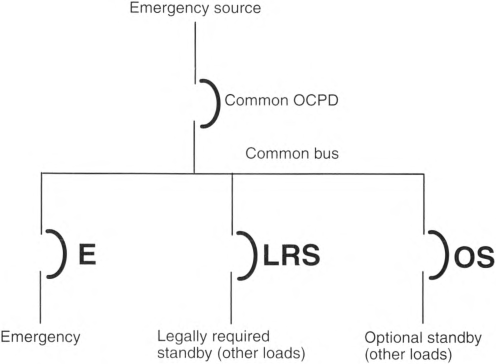

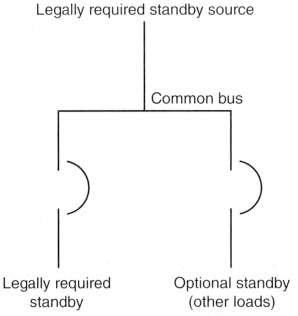

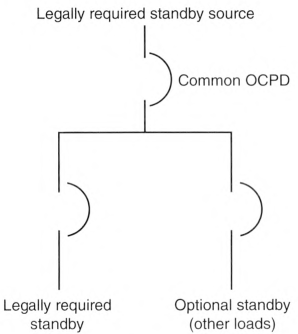

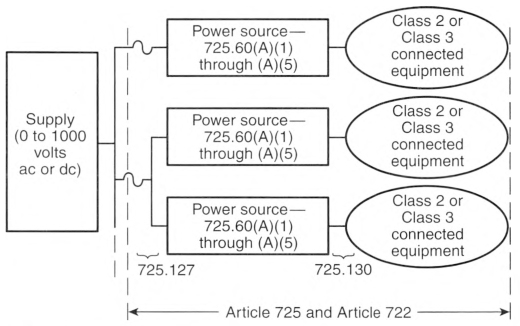

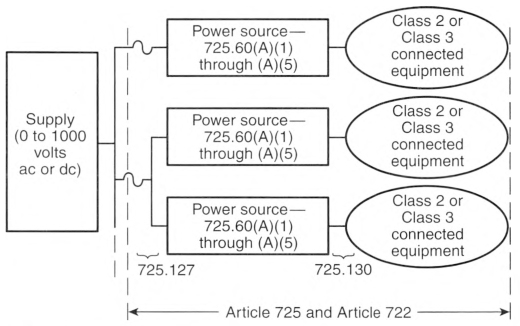

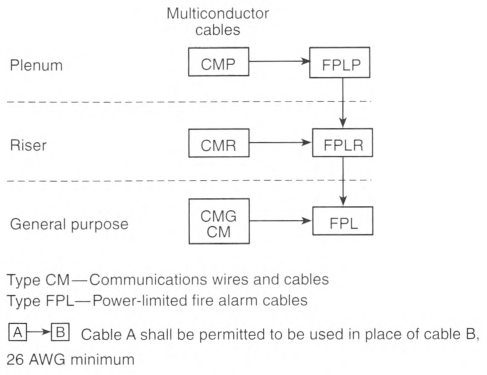

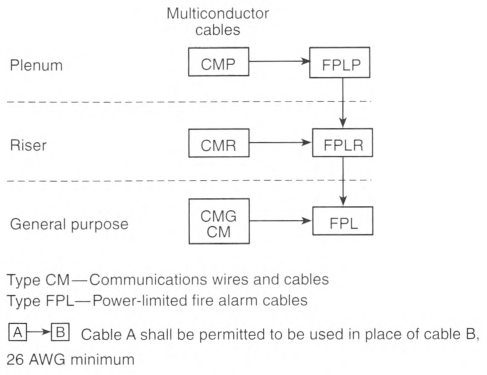

- Supplied by single or multiple feeders with overcurrent protection, provided that the overcurrent protection that is common to an emergency system and any nonemergency system(s) is selectively coordinated with the next downstream overcurrent protective device in the nonemergency system(s)Informational Note: See Informational Note Figure 700.10(B)(1) and Informational Note Figure 700.10(B)(2) for further information.

- Emergency circuits shall not originate from the same vertical switchgear section, vertical switchboard section, panelboard enclosure, or individual disconnect enclosure as other circuits.

- It shall be permissible to use single or multiple feeders to supply distribution equipment between an emergency source and the point where the emergency loads are separated from all other loads.

- At the emergency power source, such as a generator, multiple integral overcurrent protective devices shall each be permitted to supply a designated emergency or a designated nonemergency load, provided that there is complete separation between emergency and nonemergency loads beginning immediately after the overcurrent protective device line-side connections.

Wiring of two or more emergency circuits supplied from the same source shall be permitted in the same raceway, cable, box, or cabinet.

Informational Note Figure 700.10(B)(1) Single or Multiple Feeders Without Overcurrent Protection..

Informational Note Figure 700.10(B)(2) Single or Multiple Feeders with Overcurrent Protection.

(C) Wiring Design and Location.

Emergency wiring circuits shall be designed and located so as to minimize the hazards that might cause failure due to flooding, fire, icing, vandalism, and other adverse conditions.

(D) Fire Protection.

(1) Occupancies.

Emergency systems shall meet the additional requirements in 700.10(D)(2) through (D)(4) in the following occupancies:

- Assembly occupancies for not less than 1000 persons

- Buildings above 23 m (75 ft) in height

- Educational occupancies with more than 300 occupants

(2) Feeder-Circuit Wiring.

Feeder-circuit wiring shall meet one of the following conditions:

- The cable or raceway is installed in spaces or areas that are fully protected by an approved automatic fire protection system.

- The cable or raceway is protected by a listed electrical circuit protective system with a minimum 2-hour fire rating.Informational Note No. 1: See UL 1724, Fire Tests for Electrical Circuit Protection Systems, for one method of defining an electrical circuit protective system. The UL Guide Information for Electrical Circuit Integrity Systems (FHIT) contains information to identify the system and its installation limitations to maintain a minimum 2-hour fire-resistive rating and is available from the certification body.

- Informational Note No. 2: See UL 2196-2017, Standard for Fire Test for Circuit Integrity of Fire-Resistive Power, Instrumentation, Control and Data Cables, for one method of defining a fire-resistive cable system.

- The cable or raceway is protected by a listed fire-rated assembly that has a minimum fire rating of 2 hours and contains only emergency circuits.

- The cable or raceway is encased in a minimum of 50 mm (2 in.) of concrete.

(3) Feeder-Circuit Equipment.

Equipment for feeder circuits (including transfer switches, transformers, and panelboards) shall be located either in spaces fully protected by an approved automatic fire protection system or in spaces with a 2-hour fire resistance rating.

(4) Source Control Wiring.

Control conductors installed between the emergency power supply system/stored-energy power supply system (EPSS/SEPSS) and transfer equipment or control systems that initiate the operation of emergency sources or initiate the automatic connection to emergency loads shall be kept entirely independent of all other wiring and shall meet the conditions of 700.10(D)(2). The integrity of source control wiring shall be monitored for broken, disconnected, or shorted wires. Loss of integrity shall result in the following actions:

- Generators. Shall start the generator(s).

- All other sources. Shall be considered a system malfunction and initiate the designated signal(s) in 700.6(A).

700.11 Wiring, Class-2-Powered Emergency Lighting Systems.

(B) Identification.

Emergency circuits shall be permanently marked so they will be readily identified as a component of an emergency circuit or system by the following methods:

- All boxes and enclosures for Class 2 emergency circuits shall be permanently marked as a component of an emergency circuit or system.

- Exposed cable, cable tray, or raceway systems shall be permanently marked to be identified as a component of an emergency circuit or system, within 900 mm (3 ft) of each connector and at intervals not to exceed 7.6 m (25 ft).

(C) Separation of Circuits.

Class 2 emergency circuits shall be wired in a listed, jacketed cable or with one of the wiring methods of Chapter 3. If installed alongside nonemergency Class 2 circuits that are bundled, Class 2 emergency circuits shall be bundled separately. If installed alongside nonemergency Class 2 circuits that are not bundled, Class 2 emergency circuits shall be separated by a nonconductive sleeve or nonconductive barrier from all other Class 2 circuits. Separation from other circuits shall comply with 725.136.

(D) Protection.

Wiring shall comply with the requirements of 300.4 and be installed in a raceway, armored or metal-clad cable, or cable tray.

Exception Exception No. 1: Section 700.11(D) shall not apply to wiring that does not exceed 1.83 m (6 ft) in length and that terminates at an emergency luminaire or an emergency lighting control device.

Exception Exception No. 2: Section 700.11(D) shall not apply to locked rooms or locked enclosures that are accessible only to qualified persons.

Informational Note: Locked rooms accessible only to qualified persons include locked telecommunications rooms, locked electrical equipment rooms, or other access-controlled areas.

700.12 General Requirements.

Current supply shall be such that, in the event of failure of the normal supply to, or within, the building or group of buildings concerned, emergency lighting, emergency power, or both shall be available within the time required for the application but not to exceed 10 seconds. The supply system for emergency purposes, in addition to the normal services to the building and meeting the general requirements of this section, shall be one or more of the types of systems described in 700.12(C) through (H). Unit equipment in accordance with 700.12(H) shall satisfy the applicable requirements of this article.

(A) Power Source Considerations.

In selecting an emergency source of power, consideration shall be given to the occupancy and the type of service to be rendered, whether of minimum duration, as for evacuation of a theater, or longer duration, as for supplying emergency power and lighting due to an indefinite period of current failure from trouble either inside or outside the building.

(B) Equipment Design and Location.

Equipment shall be designed and located so as to minimize the hazards that might cause complete failure due to flooding, fires, icing, and vandalism.

Equipment for sources of power as described in 700.12(C) through (H) shall be installed either in spaces fully protected by approved automatic fire protection systems or in spaces with a 2-hour fire rating where located within the following:

- Assembly occupancies for more than 1000 persons

- Buildings above 23 m (75 ft) in height

- Educational occupancies with more than 300 occupants

Informational Note No. 1: See NFPA 101-2021, Life Safety Code, Section 6.1, for information on occupancy classifications.

Informational Note No. 2: See IEEE 3006.5-2014, Recommended Practice for the Use of Probability Methods for Conducting a Reliability Analysis of Industrial and Commercial Power Systems, for information regarding power system reliability.

(C) Supply Duration.

The emergency power source shall be of suitable rating and capacity to supply and maintain the total load for the duration determined by the system design. In no case shall the duration be less than 2 hours of system operation unless used for emergency illumination in 700.12(C)(4) or unit equipment in 700.12(H). Additionally, the power source shall comply with 700.12(C)(1) through (C)(5) as applicable.

Informational Note: See NFPA 110-2022, Standard for Emergency and Standby Power Systems, for information on classification of emergency power supply systems (EPSS).

(1) On-Site Fuel Supply.

An on-site fuel supply shall be provided, sufficient for not less than 2 hours operation of the system.

(2) Fuel Transfer Pumps.

Where power is needed for the operation of the fuel transfer pumps to deliver fuel to the source, these pumps shall be connected to the emergency power system.

(3) Public Gas System, Municipal Water Supply.

Sources shall not be solely dependent on a public utility gas system for their fuel supply or municipal water supply for their cooling systems.

Exception: Where approved by the authority having jurisdiction, the use of other than on-site fuels shall be permitted where there is a low probability of a simultaneous failure of both the off-site fuel delivery system and power from the outside electrical utility company. Where the public gas system is approved, the requirements of 700.12(C)(1) shall not apply.

(4) Storage Batteries and UPS.

Storage batteries and UPS used to supply emergency illumination shall be of suitable rating and capacity to supply and maintain the total load for a minimum period of 11/2 hours, without the voltage applied to the load falling below 871/2 percent of nominal voltage. Automotive-type batteries shall not be used. An automatic battery charging means shall be provided.

(5) Automatic Fuel Transfer.

Where dual fuel sources are used, means shall be provided for automatically transferring from one fuel source to another.

(D) Generator Set.

(1) Prime Mover-Driven.

For a generator set driven by a prime mover approved by the authority having jurisdiction and sized in accordance with 700.4, means shall be provided for automatically starting the prime mover on failure of the normal power source and for automatic transfer and operation of all required electrical circuits. A time-delay feature shall be provided to avoid retransfer in case of short-time reestablishment of the normal source.

(2) Battery Power and Dampers.

Where a storage battery is used for control or signal power or as the means of starting the prime mover, it shall be suitable for the purpose and shall be equipped with an automatic charging means independent of the generator set. Where the battery charger is required for the operation of the generator set, it shall be connected to the emergency system. Where power is required for the operation of dampers used to ventilate the generator set, the dampers shall be connected to the emergency system.

(3) Auxiliary Power Supply.

Generator sets that require more than 10 seconds to develop power shall be permitted if an auxiliary power supply energizes the emergency system until the generator can pick up the load.

(4) Outdoor Generator Sets.

Where an outdoor-housed generator set is equipped with a readily accessible disconnecting means in accordance with 445.18, and the disconnecting means is located within sight of the building or structure supplied, an additional disconnecting means shall not be required where ungrounded conductors serve or pass through the building or structure. Where the generator supply conductors terminate at a disconnecting means in or on a building or structure, the disconnecting means shall meet the requirements of 225.36.

Exception: For installations under single management, where conditions of maintenance and supervision ensure that only qualified persons will monitor and service the installation and where documented safe switching procedures are established and maintained for disconnection, the generator set disconnecting means shall not be required to be located within sight of the building or structure served.

(E) Stored-Energy Power Supply Systems (SEPSS).

(1) Types.

Systems shall consist of one or more of the following system types:

- Informational Note: See UL 1778, Uninterruptible Power Systems, for further information.

- Fuel cell system

- Energy storage system (ESS)

- Storage battery

- Other approved equivalent stored energy sources that comply with 700.12

(2) Fire Protection, Suppression, Ventilation, and Separation.

The systems in 700.12(E)(1) shall be installed with the fire protection, suppression, ventilation, and separation requirements specified in the manufacturer's instructions or equipment listing.

Informational Note: See NFPA 853-2020, Standard for the Installation of Stationary Fuel Cell Power Systems, and NFPA 855-2020, Standard for the Installation of Stationary Energy Storage Systems, for additional information on fire protection installation requirements.

(F) Separate Service.

Where approved by the authority having jurisdiction as suitable for use as an emergency source of power, an additional service shall be permitted. This service shall be in accordance with the applicable provisions of Article 230 and the following additional requirements:

- Separate overhead service conductors, service drops, underground service conductors, or service laterals shall be installed.

- The service conductors for the separate service shall be installed sufficiently remote electrically and physically from any other service conductors to minimize the possibility of simultaneous interruption of supply.

(G) Microgrid Systems.

On-site sources, designated as emergency sources, shall be permitted to be connected to a microgrid system.

The system shall isolate the emergency system from all nonemergency loads when the normal electric supply is interrupted or shall meet the requirements of 700.4(B). Interruption or partial or complete failure of the normal or nonemergency source(s) shall not impact the availability, capacity, and duration provided by the designated emergency sources.

The designated stored-energy electrical emergency power source(s) of a microgrid system shall be permitted to remain interconnected to any available power production source during operation of the emergency source(s) where the lack of, or failure of, the interconnected power production source(s), or related controls, does not impact system operation. Interconnected power production sources, other than the designated stored emergency power source(s), shall not be required to meet the requirements of this article.

(H) Battery-Equipped Emergency Luminaires.

(1) Listing.

All battery-equipped emergency luminaires shall be listed.

Informational Note No. 1: See ANSI/UL 924, Emergency Lighting and Power Equipment, for the requirements covering battery-equipped emergency luminaires and emergency battery packs. A listed emergency battery pack installed in a listed luminaire will provide similar functionality as a listed battery-equipped emergency luminaire.

(2) Installation.

Battery-equipped emergency luminaires shall be installed in accordance with the following:

- Battery-equipped emergency luminaires shall be permanently fixed in place (i.e., not portable).

- Wiring to each luminaire shall be installed in accordance with the requirements of any of the wiring methods in Chapter 3 unless otherwise specified in Part II, IV, or V of this article. Flexible cord-and-plug connection shall be permitted for unit equipment, provided that the cord does not exceed 900 mm (3 ft) in length. Flexible cord, with or without a plug, shall also be permitted for battery-equipped emergency luminaires installed in accordance with 410.62(C)(1).

- The branch circuit feeding the battery-equipped emergency luminaire shall be one of the following:

- The same branch circuit as that serving the normal lighting in the area and connected ahead of any local switches.

- The same or a different branch circuit as that serving the normal lighting in the area if that circuit is equipped with means to monitor the status of that area's normal lighting branch circuit ahead of any local switches.

- A separate branch circuit originating from the same panelboard as one or more normal lighting circuits. This separate branch circuit disconnecting means shall be provided with a lock-on feature.

- The branch circuit that feeds battery-equipped emergency luminaires shall be clearly identified at the distribution panel.

- Emergency luminaires that obtain power from a battery-equipped emergency luminaire shall be wired to the battery-equipped emergency luminaires as required in Part II, IV, or V of this article.

- Remote luminaires providing lighting for the exterior of an exit door shall be permitted to be supplied by the battery-equipped emergency luminaire serving the area immediately inside the exit door.

700.15 Loads on Emergency Branch Circuits.

No appliances and no lamps, other than those specified as required for emergency use, shall be supplied by emergency lighting circuits.

700.16 Emergency Illumination.

(A) General.

Emergency illumination shall include means of egress lighting, illuminated exit signs, and all other luminaires specified as necessary to provide required illumination.

(B) System Reliability.

Emergency lighting systems shall be designed and installed so that the failure of any illumination source cannot leave in total darkness any space that requires emergency illumination. Emergency lighting control devices in the emergency lighting system shall be listed for use in emergency systems. Listed unit equipment in accordance with 700.12(H) shall be considered as meeting the provisions of this section.

(C) Discharge Lighting.

Where high-intensity discharge lighting such as high- and low-pressure sodium, mercury vapor, and metal halide is used as the sole source of normal illumination, the emergency lighting system shall be required to operate until normal illumination has been restored.

(D) Disconnecting Means.

Where an emergency system is installed, emergency illumination shall be provided in the area of the disconnecting means required by 225.31 and 230.70, as applicable, where the disconnecting means are installed indoors.

Exception: Alternative means that ensure that the emergency lighting illumination level is maintained shall be permitted.

700.17 Branch Circuits for Emergency Lighting.

Branch circuits that supply emergency lighting shall be installed to provide service from a source complying with 700.12 when the normal supply for lighting is interrupted. Such installations shall provide either of the following:

- An emergency lighting supply, independent of the normal lighting supply, with provisions for automatically transferring the emergency lights upon the event of failure of the normal lighting supply.

- Two or more branch circuits supplied from separate and complete systems with independent power sources. One of the two power sources and systems shall be part of the emergency system, and the other shall be permitted to be part of the normal power source and system. Each system shall provide sufficient power for emergency lighting purposes.

Unless both systems are used for regular lighting purposes and both are kept lighted, means shall be provided for automatically energizing either system upon failure of the other. Either system or both systems shall be permitted to be a part of the general lighting of the protected occupancy if circuits supplying lights for emergency illumination are installed in accordance with other sections of this article.

700.18 Circuits for Emergency Power.

For branch circuits that supply equipment classed as emergency, there shall be an emergency system supply source to which the load will be transferred automatically upon the failure of the normal supply.

700.19 Multiwire Branch Circuits.

The branch circuit serving emergency lighting and power circuits shall not be part of a multiwire branch circuit.

700.20 Switch Requirements.

The switch or switches installed in emergency lighting circuits shall be arranged so that only authorized persons have control of emergency lighting.

Exception No. I: Where two or more single-throw switches are connected in parallel to control a single circuit, at least one of these switches shall be accessible only to authorized persons.

Exception No. 2: Additional switches that act only to put emergency lights into operation but not disconnect them shall be permissible.

Switches connected in series or 3- and 4-way switches shall not be used.

700.21 Switch Location.

All manual switches for controlling emergency circuits shall be in locations convenient to authorized persons responsible for their actuation. In facilities covered by Articles 518 and 520, a switch for controlling emergency lighting systems shall be located in the lobby or at a place conveniently accessible thereto.

In no case shall a control switch for emergency lighting be placed in a motion-picture projection booth or on a stage or platform.

Exception: Where multiple switches are provided, one such switch shall be permitted in such locations where arranged so that it can only energize the circuit but cannot de-energize the circuit.

700.23 Dimmer and Relay Systems.

A dimmer or relay system containing more than one dimmer or relay and listed for use in emergency systems shall be permitted to be used as a control device for energizing emergency lighting circuits. Upon failure of normal power, the dimmer or relay system shall be permitted to selectively energize only those branch circuits required to provide minimum emergency illumination using a control bypass function. Where the dimmer or relay system is fed by a normal/emergency power source from an upstream transfer switch, normal power sensing for this function shall be permitted to be from a normal-only power source upstream of the transfer switch. All branch circuits supplied by the dimmer or relay system cabinet shall comply with the wiring methods of Part II of Article 700.

700.24 Directly Controlled Emergency Luminaires.

Where emergency illumination is provided by one or more directly controlled emergency luminaires that, upon loss of normal power, respond to an external control input to establish the required emergency illumination level, such directly controlled emergency luminaries shall be listed for use in emergency systems. Luminaires that are energized to the required emergency illumination level by disconnection of their control input by a listed emergency lighting control device shall not be required to be listed for use in emergency systems.

700.25 Branch Circuit Emergency Lighting Transfer Switch.

Emergency lighting loads supplied by branch circuits rated at not greater than 20 amperes shall be permitted to be transferred from the normal branch circuit to an emergency branch circuit using a listed branch circuit emergency lighting transfer switch. The mechanically held requirement of 700.5(C) shall not apply to listed branch circuit emergency lighting transfer switches.

700.30 Accessibility.

The branch-circuit overcurrent devices in emergency circuits shall be accessible to authorized persons only.

700.31 Ground-Fault Protection of Equipment.

The alternate source for emergency systems shall not be required to provide ground-fault protection of equipment with automatic disconnecting means. Ground-fault indication at the emergency source shall be provided in accordance with 700.6(D) if ground-fault protection of equipment with automatic disconnecting means is not provided.

700.32 Selective Coordination.

(A) General.

Emergency system(s) overcurrent protective devices (OCPDs) shall be selectively coordinated with all supply-side and load-side OCPDs.

Selective coordination shall be selected by a licensed professional engineer or other qualified persons engaged primarily in the design, installation, or maintenance of electrical systems. The selection shall be documented and made available to those authorized to design, install, inspect, maintain, and operate the system.

(B) Replacements.

Where emergency system(s) OCPDs are replaced, they shall be reevaluated to ensure selective coordination is maintained with all supply-side and load-side OCPDs.

(C) Modifications.

If modifications, additions, or deletions to the emergency system(s) occur, selective coordination of the emergency system(s) OCPDs with all supply-side and load-side OCPDs shall be reevaluated.

Exception: Selective coordination shall not be required between two overcurrent devices located in series if no loads are connected in parallel with the downstream device.

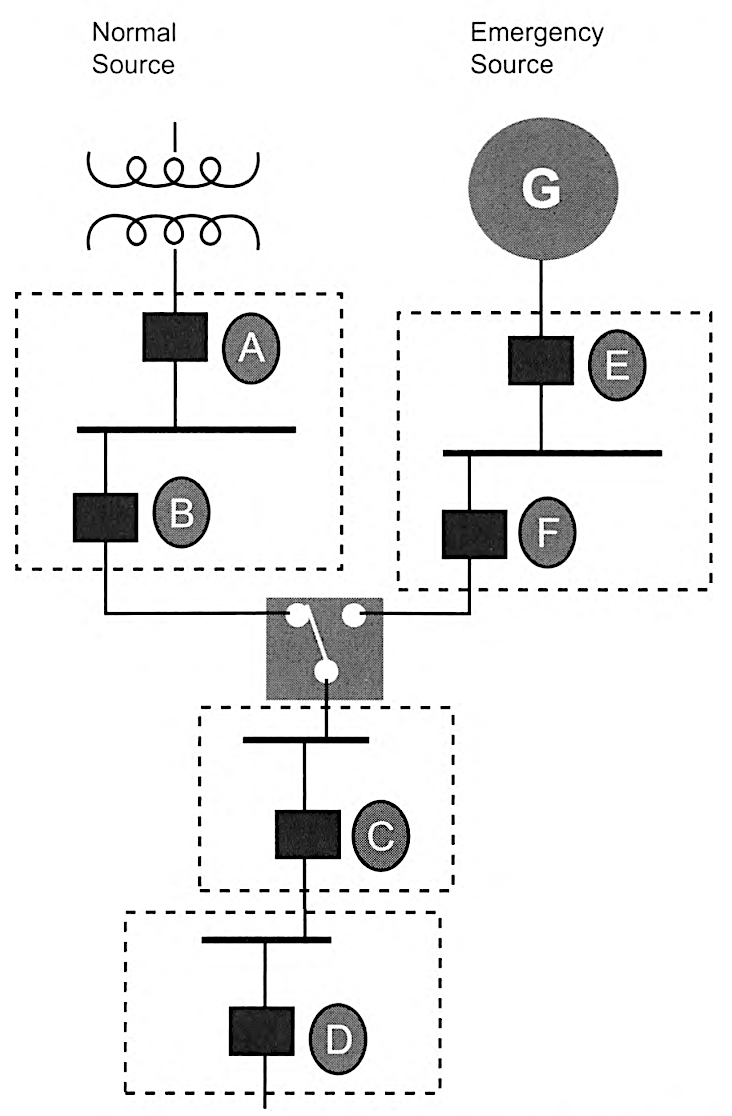

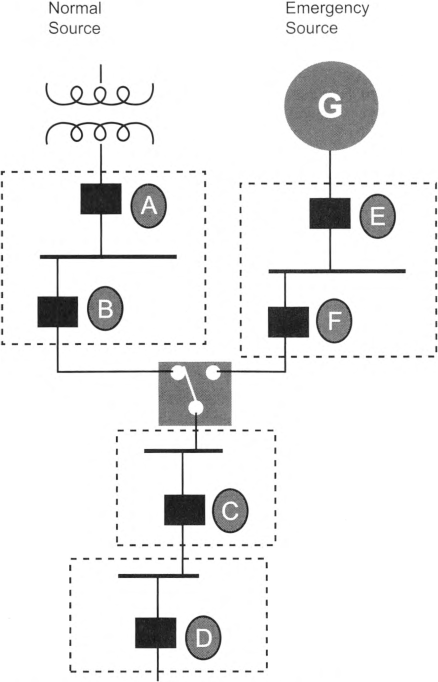

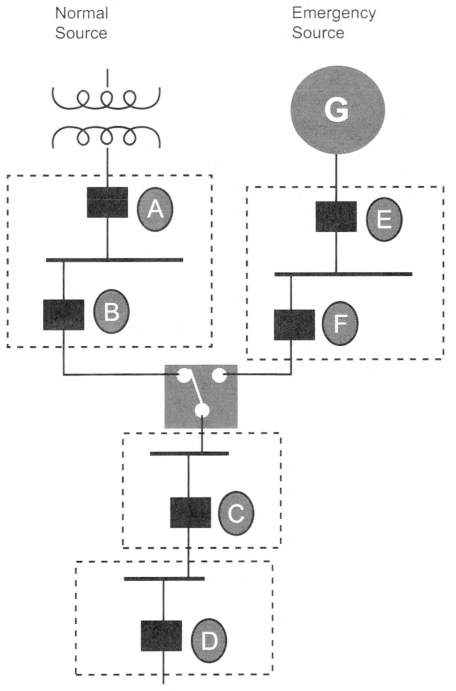

Informational Note: See Informational Note Figure 700.32(C) for an example of how emergency system OCPDs selectively coordinate with all supply-side OCPDs.

OCPD D selectively coordinates with OCPDs C, F, E, B, and A.

OCPD C selectively coordinates with OCPDs F, E, B, and A.

OCPD F selectively coordinates with OCPD E.

OCPD B is not required to selectively coordinate with OCPD A because OCPD B is not an emergency system OCPD.

Informational Note Figure 700.32(C) Emergency System Selective Coordination.

Article 701

Legally Required Standby Systems

701.1 Scope.

This article applies to the electrical safety of the installation, operation, and maintenance of legally required standby systems consisting of circuits and equipment intended to supply, distribute, and control electricity to required facilities for illumination or power, or both, when the normal electrical supply or system is interrupted.

The systems covered by this article consist only of those that are permanently installed in their entirety, including the power source.

Informational Note No. 1: See NFPA 99-2018, Health Care Facilities Code, for further information.

Informational Note No. 2: See NFPA 110-2019, Standard for Emergency and Standby Power Systems, for further information regarding performance of emergency and standby power systems.

Informational Note No. 3: See ANSI/IEEE 446-1995, Recommended Practice for Emergency and Standby Power Systems for Industrial and Commercial Applications, for further information.

Informational Note No. 4: Legally required standby systems are typically installed to serve loads, such as heating and refrigeration systems, communications systems, ventilation and smoke removal systems, sewage disposal systems, lighting systems, and industrial processes that, when stopped during any interruption of the normal electrical supply, could create hazards or hamper rescue or firefighting operations.

Informational Note No. 5: Legally required standby systems are considered level one systems when failure to perform could result in loss of human life or serious injuries and level two systems when failure of legally required standby systems to perform is less critical to human life and safety when applying NFPA 110-2019, Standard for Emergency Standby Power Systems.

701.3 Commissioning and Maintenance.

(A) Commissioning Witness Test.

The authority having jurisdiction shall conduct or witness the commissioning of the complete system upon installation.

(B) Tested Periodically.

Systems shall be tested periodically on a schedule and in a manner approved by the authority having jurisdiction to ensure the systems are maintained in proper operating condition.

(C) Maintenance.

Legally required standby system equipment shall be maintained in accordance with manufacturer instructions and industry standards.

(D) Written Record.

A written record shall be kept on such tests and maintenance.

(E) Testing Under Load.

Means for testing legally required standby systems under load shall be provided.

Informational Note: See NFPA 110-2019, Standard for Emergency and Standby Power Systems, for information on testing and maintenance of emergency power supply systems (EPSSs).

701.4 Capacity and Rating.

(A) Rating.

Legally required standby system equipment shall be suitable for the available fault current at its terminals.

(B) Capacity.

A legally required standby system shall have adequate capacity in accordance with Parts I through IV of Article 220 or by another approved method. The system capacity shall be sufficient for the rapid load changes and transient power and energy requirements associated with any expected loads.

(C) Load Management.

The alternate power source shall be permitted to supply legally required standby and optional standby system loads where the alternate source has adequate capacity or where load management (that includes automatic selective load pickup and load shedding) is provided that will ensure adequate power to the legally required standby circuits.

(D) Parallel Operation.

Parallel operation shall comply with Part I or Part II of Article 705 where the legally required source capacity required to supply the legally required load is maintained at all times. Parallel operation of the legally required source(s) shall consist of the sources specified in 701.4(D)(1) and (D)(2).

(1) Normal Source.

The alternate power source shall be permitted to operate in parallel with the normal source in compliance with Part I or Part II of Article 705 where the capacity required to supply the legally required standby load is maintained at all times. Any operating condition that results in less than the required source capacity shall initiate a legally required standby source malfunction signal in 701.6(A).

Parallel operation shall be permitted for satisfying the test requirements of 701.3(B), provided all other conditions of 701.3 are met.

Informational Note: Peak load shaving is one application for parallel source operation.

(2) Alternate Source.

Legally required standby sources shall be permitted to operate in parallel where the necessary equipment to establish and maintain a synchronous condition is provided.

701.5 Transfer Equipment.

(A) General.

Transfer equipment shall be automatic, listed, and marked for emergency system or legally required standby use. Transfer equipment shall be designed and installed to prevent the inadvertent interconnection of normal and alternate sources of supply in any operation of the transfer equipment. Transfer equipment and electric power production systems installed to permit operation in parallel with the normal source shall meet the requirements of Article 705. Meter-mounted transfer switches shall not be permitted for legally required system use.

(B) Bypass Isolation Switches.

Means to bypass and isolate the transfer switch equipment shall be permitted. Where bypass isolation switches are used, inadvertent parallel operation shall be avoided.

(D) Documentation.

The short-circuit current rating of the transfer equipment, based on the specific overcurrent protective device type and settings protecting the transfer equipment, shall be field marked on the exterior of the transfer equipment.

701.6 Signals.

Audible and visual signal devices shall be provided, where practicable, for the purposes described in 701.6(A), (B), (C), and (D).

(A) Malfunction.

Malfunction signals indicate a malfunction of the standby source.

(B) Carrying Load.

Load carrying signals indicate that the standby source is carrying load.

(C) Battery Charging Malfunction.

Battery charging malfunction signals indicate charging malfunction on a battery required for source readiness, including the prime mover starting battery.

Informational Note: See NFPA 110-2019, Standard for Emergency and Standby Power Systems, for signals for generator sets.

(D) Ground Fault.

Ground-fault signals indicate a ground fault in solidly grounded wye, legally required standby systems of more than 150 volts to ground and circuit-protective devices rated 1000 amperes or more. The sensor for the ground-fault signal devices shall be located at, or ahead of, the main system disconnecting means for the legally required standby source, and the maximum setting of the signal devices shall be for a ground-fault current of 1200 amperes. Instructions on the course of action to be taken in the event of an indicated ground fault shall be located at or near the sensor location.

For systems with multiple emergency sources connected to a paralleling bus, the ground-fault sensor shall be permitted at an alternate location.

Informational Note: See NFPA 110-2019, Standard for Emergency and Standby Power Systems, for signals for generator sets.

701.7 Signs.

(A) Mandated Standby.

A sign shall be placed at the service entrance indicating type and location of each on-site legally required standby power source.

Exception: A sign shall not be required for individual unit equipment as specified in 701.12(1).

(B) Grounding.

Where removal of a grounding or bonding connection in normal power source equipment interrupts the grounding electrode conductor connection to the alternate power source(s) grounded conductor, a warning sign shall be installed at the normal power source equipment stating:

WARNING

SHOCK HAZARD EXISTS IF GROUNDING ELECTRODE

CONDUCTOR OR BONDING JUMPER CONNECTION IN

THIS EQUIPMENT IS REMOVED WHILE ALTERNATE

SOURCE(S) IS ENERGIZED..

The warning sign(s) or label(s) shall comply with 110.21(B).

701.10 Wiring Legally Required Standby Systems.

(B) Wiring.

Wiring from a legally required source to supply legally required and other (nonlegally required) loads shall be in accordance with the following:

- The common bus of switchgear, sections of a switchboard, or individual enclosures shall be either of the following:

- Supplied by single or multiple feeders without overcurrent protection at the source

- Supplied by single or multiple feeders with overcurrent protection, provided that the overcurrent protection that is common to a legally required system and any nonlegally required system(s) is selectively coordinated with the next downstream overcurrent protective device in the nonlegally required system(s)

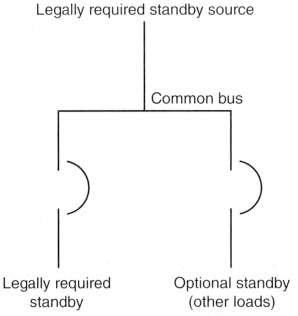

Informational Note: See Informational Note Figure 701.10(B)(1) and Informational Note Figure 701.10(B)(2) for further information.

Informational Note: See Informational Note Figure 701.10(B)(1) Single or Multiple Feeders Without Overcurrent Protection..

Informational Note Figure 701.10(B)(2) Single or Multiple Feeders with Overcurrent Protection.

701.12 General Requirements.

Current supply shall be such that, in the event of failure of the normal supply to, or within, the building or group of buildings concerned, legally required standby power will be available within the time required for the application but not to exceed 60 seconds. The supply system for legally required standby purposes, in addition to the normal services to the building, shall be permitted to comprise one or more of the types of systems described in 701.12(A) through (I). Unit equipment in accordance with 701.12(1) shall satisfy the applicable requirements of this article.

(A) Power Source Considerations.

In selecting a legally required standby source of power, consideration shall be given to the type of service to be rendered, whether of short-time duration or long duration.

(B) Equipment Design and Location.

Consideration shall be given to the location or design, or both, of all equipment to minimize the hazards that might cause complete failure due to floods, fires, icing, and vandalism.

Informational Note: See ANSI/IEEE 493-2007, Recommended Practice for the Design of Reliable Industrial and Commercial Power Systems, for further information.

(C) Supply Duration.

The alternate power source shall be of suitable rating and capacity to supply and maintain the total load for the duration determined by the system design. In no case shall the duration be less than 2 hours of system operation. Additionally, the power source shall comply with 701.12(C)(1) through (C)(5) as applicable.

Informational Note: See NFPA 110-2022, Standard for Emergency and Standby Power Systems, for information on classification of emergency power supply systems (EPSS).

(1) On-Site Fuel Supply.

An on-site fuel supply shall be provided, sufficient for not less than 2 hours operation of the system.

(2) Fuel Transfer Pumps.

Where power is needed for the operation of the fuel transfer pumps to deliver fuel to the source, these pumps shall be connected to the legally required standby power system.

(3) Public Gas System, Municipal Water Supply.

Sources shall not be solely dependent on a public utility gas system for their fuel supply or on a municipal water supply for their cooling systems.

Exception: Where approved by the authority having jurisdiction, the use of other than on-site fuels shall be permitted where there is a low probability of a simultaneous failure of both the off-site fuel delivery system and power from the outside electrical utility company. Where a public gas system is approved, the requirements of 701.12(C)(1) shall not apply.

(4) Storage Batteries and UPS.

Storage batteries and UPS used to supply standby illumination shall be of suitable rating and capacity to supply and maintain the total load for a minimum period of 11/2 hours, without the voltage applied to the load falling below 871/2 percent of nominal voltage. Automotive-type batteries shall not be used. An automatic battery charging means shall be provided.

(5) Automatic Fuel Source Transfer.

Where dual fuel sources are used, means shall be provided for automatically transferring from one fuel source to another.

(D) Generator Set.

(1) Prime Mover-Driven.

For a generator set driven by a prime mover approved by the authority having jurisdiction and sized in accordance with 701.4, means shall be provided for automatically starting the prime mover upon failure of the normal power source and for automatic transfer and operation of all required electrical circuits. A time-delay feature permitting a 15-minute setting shall be provided to avoid retransfer in case of short-time reestablishment of the normal source.

(2) Battery Power.

Where a storage battery is used for control or signal power or as the means of starting the prime mover, it shall be suitable for the purpose and shall be equipped with an automatic charging means independent of the generator set.

(3) Outdoor Generator Sets.

If an outdoor-housed generator set is equipped with a readily accessible disconnecting means in accordance with 445.18, and the disconnecting means is located within sight of the building or structure supplied, an additional disconnecting means shall not be required where ungrounded conductors serve or pass through the building or structure. Where the generator supply conductors terminate at a disconnecting means in or on a building or structure, the disconnecting means shall meet the requirements of 225.36.

(E) Stored-Energy Power Supply Systems (SEPSS).

(1) Types.

Systems shall consist of one or more of the following system types:

- Informational Note: See UL 1778, Uninterruptable Power Systems, and UL 924, Emergency Lighting and Power Equipment, for further information.

- Fuel cell system

- Energy storage system (ESS)

- Storage battery

- Other approved equivalent stored energy sources that comply with 701.12

(2) Fire Protection, Suppression, Ventilation, and Separation.

The systems in 701.12(E)(1) shall be installed with the fire protection, suppression, ventilation, and separation requirements specified in the manufacturer's instructions or equipment listing.

Informational Note: See NFPA 853-2020, Standard for the Installation of Stationary Fuel Cell Power Systems, and NFPA 855-2020, Standard for the Installation of Stationary Energy Storage Systems, for additional information on fire protection installation requirements.

(F) Separate Service.

Where approved, by the authority having jurisdiction as suitable for use as a legally required source of power, an additional service shall be permitted. This service shall be in accordance with Article 230 and the following additional requirements:

- Separate overhead service conductors, service drops, underground service conductors, or service laterals shall be installed.

- The service conductors for the separate service shall be installed sufficiently remote electrically and physically from any other service conductors to minimize the possibility of simultaneous interruption of supply.

(G) Connection Ahead of Service Disconnecting Means.

Where approved by the authority having jurisdiction, connections located ahead of and not within the same cabinet, enclosure, vertical switchgear section, or vertical switchboard section as the service disconnecting means shall be permitted. The legally required standby service shall be sufficiently separated from the normal main service disconnecting means to minimize simultaneous interruption of supply through an occurrence within the building or groups of buildings served.

Informational Note: See 230.82 for equipment permitted on the supply side of a service disconnecting means.

(H) Microgrid Systems.

On-site sources, designated as legally required standby sources, shall be permitted to be connected to a microgrid system.

The system shall isolate the legally required standby system from all nonlegally required loads when the normal electric supply is interrupted or shall meet the requirements of 701.4(C). Interruption or partial or complete failure of the normal source(s) shall not impact the availability, capacity, and duration provided by the designated legally required standby sources.

The designated stored-energy legally required standby power source(s) of a microgrid system shall be permitted to remain interconnected to any available power production source during operation of the legally required standby source(s) where the lack of, or failure of, the interconnected power production source(s), or related controls, does not impact system operation. Interconnected power production sources, other than the designated SEPSS, shall not be required to meet the requirements of this article.

(I) Battery-Equipped Emergency Luminaires, Used for Legally Required Standby Systems.

Battery-equipped emergency luminaires used for legally required standby systems shall comply with 700.12(H).

701.30 Accessibility.

The branch-circuit overcurrent devices in legally required standby circuits shall be accessible to authorized persons only.

701.31 Ground-Fault Protection of Equipment.

The alternate source for legally required standby systems shall not be required to provide ground-fault protection of equipment with automatic disconnecting means. Ground-fault indication at the legally required standby source shall be provided in accordance with 701.6(D) if ground-fault protection of equipment with automatic disconnecting means is not provided.

701.32 Selective Coordination.

(A) General.

Legally required standby system(s) overcurrent protective devices (OCPDs shall be selectively coordinated with all supply-side and load-side OCPDs.

Selective coordination shall be selected by a licensed professional engineer or other qualified persons engaged primarily in the design, installation, or maintenance of electrical systems. The selection shall be documented and made available to those authorized to design, install, inspect, maintain, and operate the system.

(B) Replacements.

Where legally required standby OCPDs are replaced, they shall be reevaluated to ensure selective coordination is maintained with all supply-side and load-side OCPDs.

(C) Modifications.

If modifications, additions, or deletions to the legally required standby system(s) occur, selective coordination of the legally required system(s) OCPDs with all supply-side and load-side OCPDs shall be reevaluated.

Exception: Selective coordination shall not be required between two overcurrent devices located in series if no loads are connected in parallel with the downstream device.

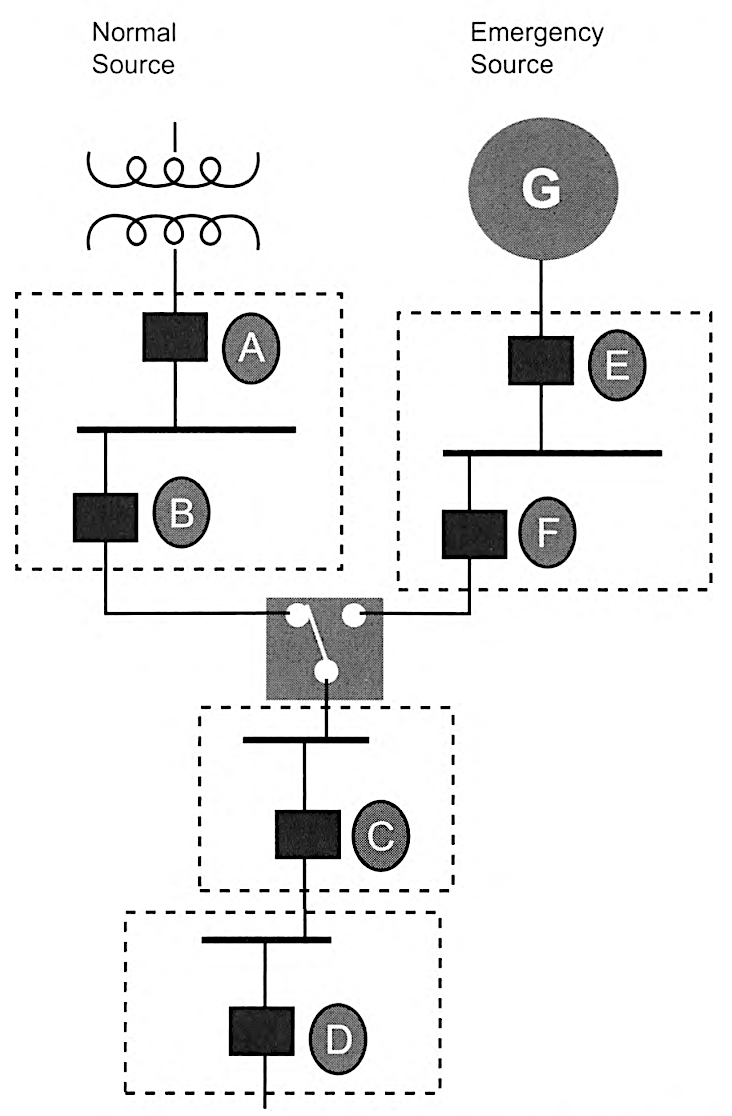

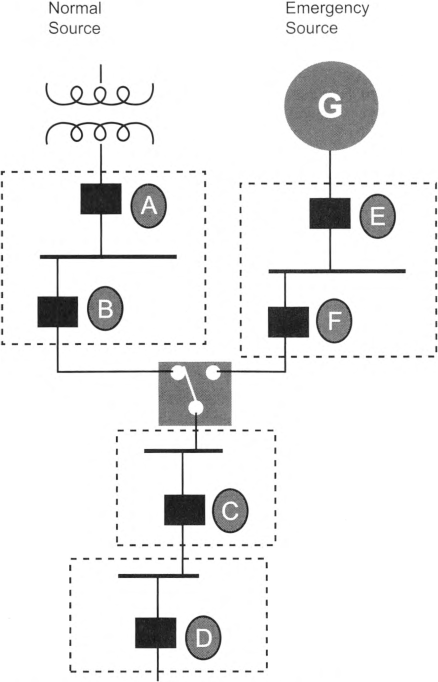

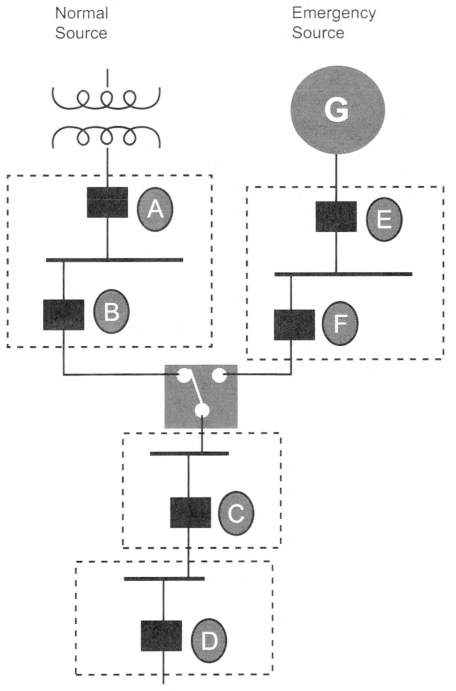

Informational Note: See Informational Note Figure 701.32(C) for an example of how legally required standby system OCPDs selectively coordinate with all supply-side OCPDs.

OCPD D selectively coordinates with OCPDs C, F, E, B, and A.

OCPD C selectively coordinates with OCPDs F, E, B, and A.

OCPD F selectively coordinates with OCPD E.

OCPD B is not required to selectively coordinate with OCPD A because OCPD B is not a legally required standby system OCPD.

Informational Note Figure 701.32(C) Legally Required Standby System Selective Coordination.

Article 702

Optional Standby Systems

702.1 Scope.

This article applies to the installation and operation of optional standby systems.

The systems covered by this article consist of those that are permanently installed in their entirety, including prime movers, and those that are arranged for a connection to a premises wiring system from a portable alternate power supply.

Informational Note: Optional standby systems are typically installed to provide an alternate source of electric power for such facilities as industrial and commercial buildings, farms, and residences and to serve loads such as heating and refrigeration systems, data processing and communications systems, and industrial processes that, when stopped during any power outage, could cause discomfort, serious interruption of the process, damage to the product or process, or the like.

702.4 Capacity and Rating.

(A) System Capacity.

(1) Manual and Nonautomatic Load Connection.

If the connection of load is manual or nonautomatic, an optional standby system shall have adequate capacity and rating for the supply of all equipment intended to be operated at one time. The user of the optional standby system shall be permitted to select the load connected to the system.

Informational Note: Manual and nonautomatic transfer equipment require human intervention.

(2) Automatic Load Connection.

If the connection of load is automatic, an optional standby system shall comply with 702.4(A)(2)(a) or (A)(2)(b) in accordance with Parts I through IV of Article 220 or by another approved method.

- Full Load. The standby source shall be capable of supplying the full load that is automatically connected.

- Energy Management System (EMS). Where a system is employed in accordance with 750.30 that will automatically manage the connected load, the standby source shall have a capacity sufficient to supply the maximum load that will be connected by the EMS.

702.5 Interconnection or Transfer Equipment.

(A) General.

Interconnection or transfer equipment shall be required for all standby systems subject to the requirements of this article. Equipment shall be suitable for the intended use and shall be listed, designed, and installed so as to prevent the inadvertent interconnection of all sources of supply in any operation of the equipment.

Exception: Temporary connection of a portable generator without transfer equipment shall be permitted where conditions of maintenance and supervision ensure that only qualified persons service the installation and where the normal supply is physically isolated by a lockable disconnecting means or by disconnection of the normal supply conductors.

(B) Meter-Mounted Transfer Switches.

Transfer switches installed between the utility meter and the meter enclosure shall be listed meter-mounted transfer switches and shall be approved.

Informational Note No. 1: See UL 1008M, Transfer Stritch Equipment, Meter Mounted, for more information.

Informational Note No. 2: Manual and nonautomatic transfer equipment use human intervention.

(C) Documentation.

In other than dwelling units, the short-circuit current rating of the transfer equipment, based on the specific overcurrent protective device type and settings protecting the transfer equipment, shall be field marked on the exterior of the transfer equipment.

(D) Parallel Installation.

Systems installed to permit operation in parallel with the normal source shall also meet Part I or Part II of Article 705.

702.6 Signals.

Audible and visual signal devices shall be provided, where practicable, for the following purposes specified in 702.6(A) and (B).

(A) Malfunction.

To indicate malfunction of the optional standby source.

(B) Carrying Load.

To indicate that the optional standby source is carrying load.

Exception: Signals shall not be required for portable standby power sources.

702.7 Signs.

(A) Standby.

A sign shall be placed at the service equipment for other than one- and two-family dwellings that indicates the type and location of each on-site optional standby power source. For one- and two-family dwelling units, a sign shall be placed at the disconnecting means required in 230.85 that indicates the location of each permanently installed on-site optional standby power source disconnect or means to shut down the prime mover as required in 445.19(C).

(B) Grounding.

Where removal of a grounding or bonding connection in normal power source equipment interrupts the grounding electrode conductor connection to the alternate power source(s) grounded conductor, a warning sign shall be installed at the normal power source equipment stating:

WARNING:

SHOCK HAZARD EXISTS IF GROUNDING ELECTRODE

CONDUCTOR OR BONDING JUMPER CONNECTION IN

THIS EQUIPMENT IS REMOVED WHILE ALTERNATE

SOURCE(S) IS ENERGIZED..

The warning sign(s) or label(s) shall comply with 110.21(B).

(C) Power Inlet.

Where a power inlet is used for a temporary connection to a portable generator, a warning sign shall be placed near the inlet to indicate the type of derived system that the system is capable of based on the wiring of the transfer equipment. The sign shall display one of the following warnings:

WARNING:

FOR CONNECTION OF A SEPARATELY DERIVED

(BONDED NEUTRAL) SYSTEM ONLY

or

WARNING:

FOR CONNECTION OF A NONSEPARATELY DERIVED

(FLOATING NEUTRAL) SYSTEM ONLY

FOR CONNECTION OF A SEPARATELY DERIVED

(BONDED NEUTRAL) SYSTEM ONLY

or

WARNING:

FOR CONNECTION OF A NONSEPARATELY DERIVED

(FLOATING NEUTRAL) SYSTEM ONLY

702.11 Portable Generator Grounding.

(A) Separately Derived System.

Where a portable optional standby source is used as a separately derived system, it shall be grounded to a grounding electrode in accordance with 250.30.

(B) Nonseparately Derived System.

Where a portable optional standby source is used as a nonseparately derived system, the equipment grounding conductor shall be bonded to the system grounding electrode.

702.12 Outdoor Generator Sets.

(A) Portable Generators Greater Than 15 kW and Permanently Installed Generators.

Where an outdoor housed generator set is equipped with a readily accessible disconnecting means in accordance with 445.18, and the disconnecting means is located within sight of the building or structure supplied, an additional disconnecting means shall not be required where ungrounded conductors serve or pass through the building or structure. Where the generator supply conductors terminate at a disconnecting means in or on a building or structure, the disconnecting means shall meet the requirements of 225.36.

(B) Portable Generators 15 kW or Less.

Where a portable generator, rated 15 kW or less, is installed using a flanged inlet or other cord-and-plug-type connection, a disconnecting means shall not be required where ungrounded conductors serve or pass through a building or structure. The flanged inlet or other cord-and-plug-type connection shall be located outside of a building or structure.

(C) Power Inlets Rated at 100 Amperes or Greater, for Portable Generators.

Equipment containing power inlets for the connection of a generator source shall be listed for the intended use. Systems with power inlets not rated as a disconnecting means shall be equipped with an interlocked disconnecting means.

Exception: Supervised industrial installations where permanent space is identified for the portable generator located within line of sight of the power inlets shall not be required to have interlocked disconnecting means nor inlets rated as disconnects.

Article 705

Interconnected Electric Power Production Sources

705.1 Scope.

This article covers installation of one or more electric power production sources operating in parallel with a primary source(s) of electricity.

Informational Note No. 1: Examples of the types of primary sources include a utility supply or an on-site electric power source(s).

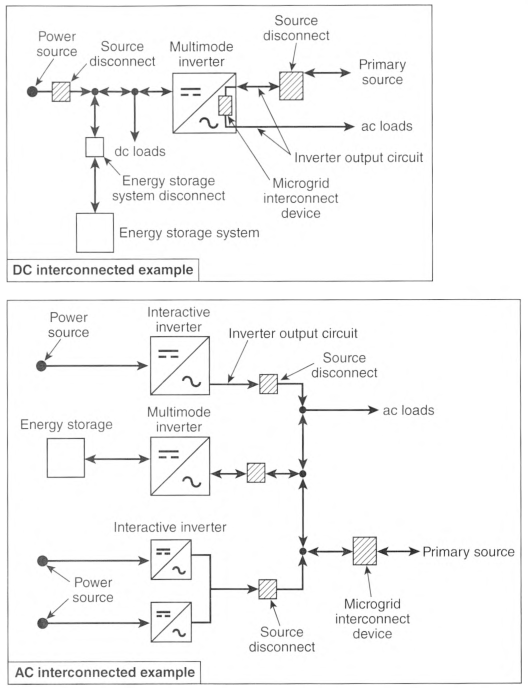

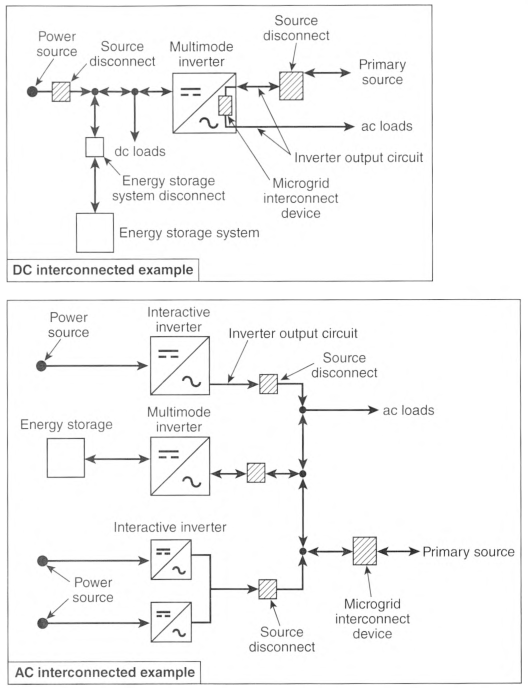

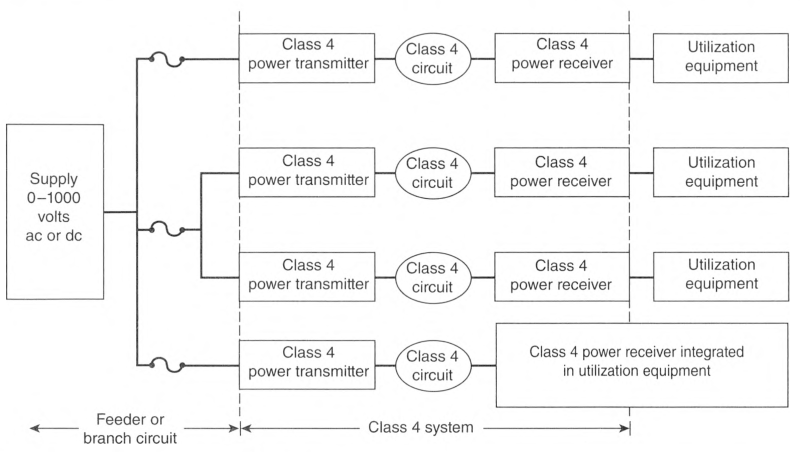

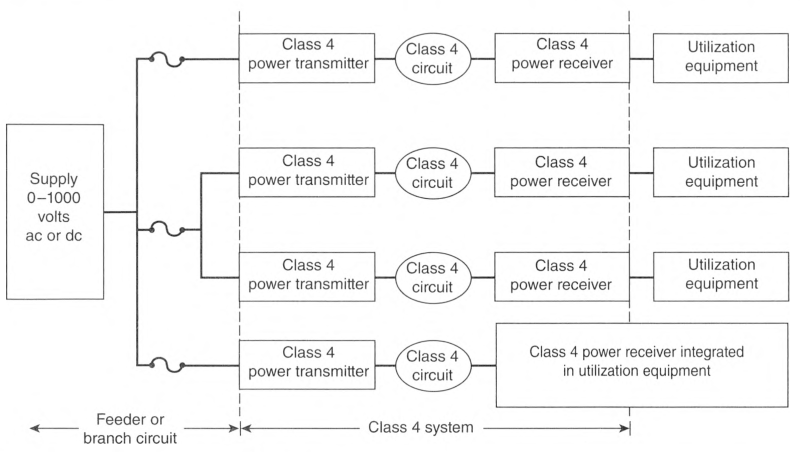

Informational Note No. 2: See Informational Note Figure 705.1.

Notes:

- These diagrams are intended to be a means of identification for power source components, circuits, and connections.

- The power source disconnect in these diagrams separates the power source from other systems.

- Equipment disconnecting means not shown.

- System grounding and equipment grounding are not shown.

- Custom designs occur in each configuration, and some components are optional.

Informational Note Figure 705.1 Identification of Power Source Components in Common Configurations

705.5 Parallel Operation.

(A) Output Compatibility.

Power production sources operating in parallel with a primary source of electricity or other power production sources shall have compatible voltage, wave shape, and frequency ratings.

(B) Synchronous Generators.

Synchronous generators operating in parallel with a primary power source shall be installed with the required synchronizing equipment.

Informational Note: See IEEE 1547, Standard for Interconnection and Interoperability of Distributed Energy Resources with Associated Electric Power Systems Interfaces, and UL 1741, Standard for Inverters, Converters, Controllers and Interconnection System Equipment for Use with Distributed Energy Resources, for utility interconnection.

705.6 Equipment Approval.

Interconnection and interactive equipment intended to connect to or operate in parallel with power production sources shall be listed for the required interactive function or be evaluated for the interactive function and have a field label applied, or both.

Informational Note No. 1: See UL 1741, Standard for Inverters, Converters, Controllers and Interconnection System Equipment for Use with Distributed Energy Resources, for evaluating interconnected equipment. Sources identified as stand-alone, interactive, or multimode are specifically identified and certified to operate in these operational modes. Stand-alone sources operate in island mode, interactive sources operate in interactive mode, and multimode sources operate in either island mode or interactive mode. Stand-alone sources are not evaluated for interactive capabilities.

Informational Note No. 2: An interactive function is common in equipment such as microgrid interconnect devices, power control systems, interactive inverters, synchronous engine generators, ac energy storage systems, and ac wind turbines.

705.8 System Installation.

Installation of one or more electrical power production sources operating in parallel with a primary source(s) of electricity shall be performed only by qualified persons.

Informational Note: See Article 100 for the definition of Qualified Person.

705.10 Identification of Power Sources.

Permanent plaques, labels, or directories shall be installed at each service equipment location, or at an approved readily visible location in accordance with the following:

- Denote the location of each power source disconnecting means for the building or structure.Exception: Installations with multiple colocated power production sources shall be permitted to be identified as a group(s). The plaque, label, or directory shall not be required to identify each power source individually.

- Indicate the emergency telephone numbers of any off-site entities servicing the power source systems.Informational Note: See NFPA 1-2021, Fire Code, 11.12.2.1.5 for installer information.

- Be marked with the wording "CAUTION: MULTIPLE SOURCES OF POWER." The marking shall comply with 110.21(B).

705.11 Source Connections to a Service.

(A) Service Connections.

An electric power production source shall be permitted to be connected to a service by one of the following methods:

- To a new service in accordance with 230.2(A)

- To the supply side of the service disconnecting means in accordance with 230.82(6)

- To an additional set of service entrance conductors in accordance with 230.40, Exception No. 5

These connections shall comply with 705.11 (B) through (F).

(B) Conductors.

Service conductors connected to power production sources shall comply with the following:

- The ampacity of the service conductors connected to the power production source service disconnecting means shall not be less than the sum of the power production source maximum circuit current in 705.28(A).

- The service conductors connected to the power production source service disconnecting means shall be sized in accordance with 705.28 and not be smaller than 6 AWG copper or 4 AWG aluminum or copper-clad aluminum.

- The ampacity of any other service conductors to which the power production sources are connected shall not be less than that required in 705.11 (B).

(C) Connections.

(2) Existing Equipment.

Any modifications to existing equipment shall be made in accordance with the manufacturer's instructions, or the modification must be field evaluated for the application and be field labeled.

(3) Utility-Controlled Equipment.

For meter socket enclosures or other equipment under the exclusive control of the electric utility, only connections approved by the electric utility shall be permitted.

(D) Service Disconnecting Means.

A disconnecting means in accordance with Parts VI through VII of Article 230 shall be provided to disconnect all ungrounded conductors of a power production source from the conductors of other systems.

(E) Bonding and Grounding.

All metal enclosures, metal wiring methods, and metal parts associated with the service connected to a power production source shall be bonded in accordance with Parts II through V and VIII of Article 250.

(F) Overcurrent Protection.

The power production source service conductors shall be protected from overcurrent in accordance with Part VII of Article 230. The rating of the overcurrent protection device of the power production source service disconnecting means shall be used to determine if ground-fault protection of equipment is required in accordance with 230.95.

705.12 Load-Side Source Connections.

The output of an interconnected electric power source shall be permitted to be connected to the load side of the service disconnecting means of the other source(s) at any distribution equipment on the premises. Where distribution equipment or feeders are fed simultaneously by a primary source of electricity and one or more other power source(s), the feeders or distribution equipment shall comply with relevant sections of 705.12(A) and (B). Currents from power source connections to feeders or busbars shall be based on the maximum circuit currents calculated in 705.28(A). The ampacity of feeders and taps shall comply with 705.12(A), and the ampere ratings of busbars shall comply with 705.12(B).

(A) Feeders and Feeder Taps.

Where the power source output connection is made to a feeder, the following shall apply:

- The feeder ampacity is greater than or equal to 125 percent of the power-source output circuit current.

- Where the power-source output connection is made at a location other than the opposite end of the feeder from the primary source overcurrent device, that portion of the feeder on the load side of the power source output connection shall be protected by one of the following:

- The feeder ampacity shall be not less than the sum of the rating of the primary source overcurrent device and 125 percent of the power-source output circuit current.

- An overcurrent device at the load side of the power source connection point shall be rated not greater than the ampacity of the feeder.

- For taps sized in accordance with 240.21(B)(2) or (B)(4). the ampacity of taps conductors shall not be less than one-third of the sum of the rating of the overcurrent device protecting the feeder plus the ratings of any power source overcurrent devices connected to the feeder.

(B) Busbars.

For power source connections to distribution equipment with no specific listing and instructions for combining multiple sources, one of the following methods shall be used to determine the required ampere ratings of busbars:

- The sum of 125 percent of the power source(s) output circuit current and the rating of the overcurrent device protecting the busbar shall not exceed the busbar ampere rating.Informational Note: This general rule assumes no limitation in the number of the loads or sources applied to busbars or their locations.

- Where two sources, one a primary power source and the other another power source, are located at opposite ends of a busbar that contains loads, the sum of 125 percent of the power-source(s) output circuit current and the rating of the overcurrent device protecting the busbar shall not exceed 120 percent of the busbar ampere rating. The busbar shall be sized for the loads connected in accordance with Article 220. A permanent warning label shall be applied to the distribution equipment adjacent to the back-fed breaker from the power source that displays the following or equivalent wording:

- The sum of the ampere ratings of all overcurrent devices on panelboards, both load and supply devices, excluding the rating of the overcurrent device protecting the busbar, shall not exceed the ampacity of the busbar. The rating of the overcurrent device protecting the busbar shall not exceed the rating of the busbar. Permanent warning labels shall be applied to distribution equipment displaying the following or equivalent wording:

- A connection at either end of a center-fed panelboard in dwellings shall be permitted where the sum of 125 percent of the power-source(s) output circuit current and the rating of the overcurrent device protecting the busbar does not exceed 120 percent of the busbar ampere rating.