Article 600

Electric Signs and Outline Lighting

600.1 Scope.

This article covers the installation of conductors, equipment, and field wiring for electric signs, retrofit kits, and outline lighting, regardless of voltage. All installations and equipment using neon tubing, such as signs, decorative elements, skeleton tubing, or art forms, are covered by this article.

Informational Note: Sign and outline lighting illumination systems include, but are not limited to, cold cathode neon tubing, high-intensity discharge lamps (HID), fluorescent or incandescent lamps, light-emitting diodes (LEDs), and electroluminescent and inductance lighting.

600.3 Listing.

Fixed, mobile, or portable electric signs, section signs, outline lighting, photovoltaic (PV) powered signs, and retrofit kits, regardless of voltage, shall be listed and labeled, provided with installation instructions, and installed in conformance with that listing, unless otherwise approved by special permission.

(A) Field-Installed Skeleton Tubing.

Field-installed skeleton tubing shall not be required to be listed where installed in conformance with this Code.

(B) Outline Lighting.

Outline lighting shall not be required to be listed as a system when it consists of listed luminaires wired in accordance with Chapter 3.

600.4 Markings.

(A) Signs and Outline Lighting Systems.

Signs and outline lighting systems shall be listed and labeled; marked with the manufacturer's name, trademark, or other means of identification; and input voltage and current rating.

(B) Signs With a Retrofitted Illumination System.

Signs with a retrofitted illumination system shall contain the following:

- The sign shall be marked that the illumination system has been replaced.

- The marking shall include the kit providers and installer's name, logo, or unique identifier.

- Signs equipped with tubular light-emitting diode lamps powered by the existing sign sockets shall include a label alerting the service personnel that the sign has been modified. The label shall meet the requirements of 110.21(B). The label shall also include a warning not to install fluorescent lamps and shall also be visible during relamping.

(C) Signs With Lampholders for Incandescent Lamps.

Signs and outline lighting systems with lampholders for incandescent lamps shall be marked to indicate the maximum allowable lamp wattage per lampholder. The markings shall be permanently installed, in letters at least 6 mm (1/4 in.) high, and shall be located where visible during relamping.

(E) Installation Instructions.

All signs, outline lighting, skeleton tubing systems, and retrofit kits shall be marked to indicate that field wiring and installation instructions are required.

Exception: Portable, cord-connected signs are not required to be marked.

600.5 Branch Circuits.

(A) Required Branch Circuit.

Each commercial building and each commercial occupancy accessible to pedestrians shall be provided with at least one outlet in an accessible location at each entrance to each tenant space for sign or outline lighting system use. The outlet(s) shall be supplied by a branch circuit rated at least 20 amperes that supplies no other load.

Exception No. 1: A sign or outline lighting outlet shall not be required at entrances for deliveries, service corridors, or service hallways that are intended to be used only by service personnel or employees.

Exception No. 2: The required branch circuit shall be permitted to supply loads directly related to the control of the sign such as electronic or electromechanical controllers.

(B) Marking.

A disconnecting means for a sign, outline lighting system, or controller shall be marked to identify the sign, outline lighting system, or controller it controls.

Exception: An external disconnecting means that is mounted on the sign body, sign enclosure, sign pole, or controller shall not be required to identify the sign or outline lighting system it controls.

(C) Rating.

Branch circuits that supply signs shall be rated in accordance with 600.5(C)(1) or (C)(2) and shall be considered to be continuous loads for the purposes of calculations.

(2) All Other Signs.

Branch circuits that supply all other signs and outline lighting systems shall be rated not to exceed 20 amperes.

(D) Wiring Methods.

(1) Supply.

The wiring method used to supply signs and outline lighting systems shall terminate within a sign, an outline lighting system enclosure, a suitable box, a conduit body, or panelboard.

(2) Enclosures as Pull Boxes.

- Listed and labeled electrical enclosures integral to the sign shall be permitted to be used for voltages up to 600 volts as pull or junction boxes for conductors supplying the following:

- Other adjacent signs

- Outline lighting systems

- Floodlights that are part of a sign

- The enclosures in 600.5(D)(2)(a) shall be permitted to contain both branch and secondary circuit conductors.

- Listed and labeled neon transformer boxes shall be permitted to contain multiple voltages over 1000 volts. A disconnecting means shall be provided to de-energize all ungrounded conductors in the enclosures.

(3) Metal or Nonmetallic Poles.

Metal or nonmetallic poles used to support signs shall be permitted to enclose supply conductors.

600.6 Disconnects.

Each sign and outline lighting system, feeder conductors, or branch circuits supplying a sign, outline lighting system, or skeleton tubing shall be controlled by an externally operable switch or circuit breaker that opens all ungrounded conductors and controls no other load. Signs and outline lighting systems located within fountains shall have the disconnect located in accordance with 680.13.

Exception No. 1: A disconnecting means shall not be required for an exit directional sign located within a building.

Exception No. 2: A disconnecting means shall not be required for cord-connected signs with an attachment plug.

Informational Note: The location of the disconnect is intended to allow service or maintenance personnel and first responders complete and local control of the disconnecting means.

(A) Location.

The disconnecting means shall be accessible and located in accordance with 600.6(A)(1), 600.6(A)(2), or 600.6(A)(3). If the disconnecting means is remote from the sign it controls, it shall comply with 600.6(A)(4).

(1) At Point of Entry to a Sign.

The disconnect shall be located at the point the feeder circuit or branch circuits supplying a sign or outline lighting system enters a sign enclosure, a sign body, or a pole in accordance with 600.5(D)(3). The disconnect shall open all ungrounded conductors where it enters the enclosure of the sign or pole.

Exception No. 1: A disconnect shall not be required for branch circuits or feeder conductors passing through the sign where not accessible and enclosed in a Chapter 3 listed raceway or metal-jacketed cable identified for the location.

Exception No. 2: A disconnect shall not be required at the point of entry to a sign enclosure or sign body for branch circuits or feeder conductors that supply an internal panelboards in a sign enclosure or sign body. The conductors shall be enclosed where not accessible in a Chapter 3 listed raceway or metal-jacketed cable identified for the location. A field-applied permanent hazard label that is visible during servicing shall be applied to the raceway at or near the point of entry into the sign enclosure or sign body. The danger label shall stale the following: "Danger. This raceway contains energized conductors." The marking shall include the location of the disconnecting means for the energized conductors. The disconnecting means shall be capable of being locked in the open position.

(2) Within Sight of the Sign.

The disconnecting means shall be within sight of the sign or outline lighting system that it controls. Where the disconnecting means is out of the line of sight from any section that is able to be energized, the disconnecting means shall be lockable in accordance with 110.25. A permanent field-applied marking identifying the location of the disconnecting means shall be applied to the sign in a location visible during servicing.

(3) Within Sight of the Controller.

The following shall apply for signs or outline lighting systems operated by electronic or electromechanical controllers located external to the sign or outline lighting system:

- The disconnecting means shall be located within sight of the controller or in the same enclosure with the controller.

- The disconnecting means shall disconnect the sign or outline lighting system and the controller from all ungrounded supply conductors.

- The disconnecting means shall be designed such that no pole can be operated independently and shall be lockable in accordance with 110.25.

Exception: Where the disconnecting means is not located within sight of the controller, a permanent field-applied marking identifying the location of the disconnecting means shall be applied to the controller in a location visible during servicing.

(4) Remote Location.

The disconnecting means, if located remote from the sign, sign body, or pole, shall be mounted at an accessible location available to first responders and service personnel. The location of the disconnect shall be marked with a label at the sign location and marked as the disconnect for the sign or outline lighting system.

(B) Control Switch Rating.

Switches, flashers, and similar devices controlling transformers and electronic power supplies shall be rated for controlling inductive loads or have a current rating not less than twice the current rating of the transformer or the electronic power supply.

600.7 Grounding and Bonding.

(A) Grounding.

(1) Equipment Grounding Conductor.

Metal equipment of signs, outline lighting, and skeleton tubing systems shall be grounded by connection to the equipment grounding conductor of the supply branch circuit(s) or feeder using the types of equipment grounding conductors specified in 250.118.

Exception: Portable cord-connected signs shall not be required to be connected to the equipment grounding conductor where protected by a system of double insulation or its equivalent. Double insulated equipment shall be distinctively marked.

(3) Connections of Equipment Grounding Conductor.

Equipment grounding conductor connections shall be made in accordance with 250.130 and in a method specified in 250.8.

(4) Auxiliary Grounding Electrode.

Auxiliary grounding electrode(s) shall be permitted for electric signs and outline lighting systems covered by this article and shall meet the requirements of 250.54.

(5) Metal Building Parts.

Metal parts of a building shall not be permitted as a secondary return conductor or an equipment grounding conductor.

(B) Bonding.

(1) Bonding of Metal Parts.

Metal parts and equipment of signs and outline lighting systems shall be bonded together and to the associated transformer or power-supply equipment grounding conductor of the branch circuit or feeder supplying the sign or outline lighting system and shall meet the requirements of 250.90.

Exception: Remote metal parts of a section sign or outline lighting system only supplied by a remote Class 2 power supply shall not be required to be bonded to an equipment grounding conductor.

(3) Metal Building Parts.

Metal parts of a building shall not be used as a means for bonding metal parts and equipment of signs or outline lighting systems together or to the transformer or power-supply equipment grounding conductor of the supply circuit.

(4) Flexible Metal Conduit Length.

Listed flexible metal conduit or listed liquidtight flexible metal conduit that encloses the secondary circuit conductor from a transformer or power supply for use with neon tubing shall be permitted as a bonding means if the total accumulative length of the conduit in the secondary circuit does not exceed 30 m (100 ft).

(5) Small Metal Parts.

Small metal parts not exceeding 50 mm (2 in.) in any dimension, not likely to be energized, and spaced at least 19 mm (3/4 in.) from neon tubing shall not require bonding.

(6) Nonmetallic Conduit.

Where listed nonmetallic conduit is used to enclose the secondary circuit conductor from a transformer or power supply and a bonding conductor is required, the bonding conductor shall be installed separate and remote from the nonmetallic conduit and be spaced at least 38 mm (11/2 in.) from the conduit when the circuit is operated at 100 Hz or less or 45 mm (13/4 in.) when the circuit is operated at over 100 Hz.

(7) Bonding Conductors.

Bonding conductors installed outside of a sign or raceway shall be protected from physical damage. Bonding conductors shall comply with 250.120 and 250.122. Bonding conductor size shall also comply with one of the following:

- Bonding conductors shall be copper and not smaller than 14 AWG.

- Bonding conductors shall be copper-clad aluminum and not smaller than 12 AWG.

(8) Signs in Fountains.

Signs or outline lighting installed inside a fountain shall have all metal parts bonded to the equipment grounding conductor of the branch circuit for the fountain recirculating system. The bonding connection shall be as near as practicable to the fountain and shall be permitted to be made to metal piping systems that are bonded in accordance with 680.54(B).

600.8 Enclosures.

Live parts, other than lamps, and neon tubing shall be enclosed. Transformers and power supplies provided with an integral enclosure, including a primary and secondary circuit splice enclosure, shall not require an additional enclosure.

(A) Strength.

Enclosures shall have ample structural strength and rigidity.

(C) Minimum Thickness of Enclosure Metal.

Sheet copper or aluminum shall be at least 0.51 mm (0.020 in.) thick. Sheet steel shall be at least 0.41 mm (0.016 in.) thick.

600.9 Location.

(A) Vehicles.

Sign or outline lighting system equipment shall be at least 4.3 m (14 ft) above areas accessible to vehicles unless protected from physical damage.

(B) Pedestrians.

Neon tubing, other than listed, dry-location, portable signs, readily accessible to pedestrians shall be protected from physical damage.

Informational Note: See 600.41(D) for additional requirements.

(C) Adjacent to Combustible Materials.

Signs and outline lighting systems shall be installed so that adjacent combustible materials are not subjected to temperatures in excess of 90°C (194°F).

The spacing between wood or other combustible materials and an incandescent or HID lamp or lampholder shall not be less than 50 mm (2 in.).

(D) Wet Location.

Signs and outline lighting system equipment for wet location use, other than listed watertight type, shall be weatherproof and have drain holes, as necessary, in accordance with the following:

- Drain holes shall not be larger than 13 mm (1/2 in.) or smaller than 6 mm (1/4 in.).

- Every low point or isolated section of the equipment shall have at least one drain hole.

- Drain holes shall be positioned such that there will be no external obstructions.

600.10 Portable or Mobile Signs.

(C) Wet or Damp Location.

(1) Cords.

All cords shall be junior hard-service or hard-service types as designated in Table 400.4 and have an equipment grounding conductor.

(2) Ground-Fault Circuit Interrupter.

In addition to the requirements in 210.8, the manufacturer of portable or mobile signs shall provide listed ground-fault circuit-interrupter protection for personnel. The ground-fault circuit interrupter shall be an integral part of the attachment plug or shall be located in the power-supply cord within 300 mm (12 in.) of the attachment plug.

600.12 Field-Installed Secondary Wiring.

Field-installed secondary circuit wiring for electric signs, retrofit kits, outline lighting systems, skeleton tubing, and photovoltaic (PV) powered sign systems shall be in accordance with their installation instructions and 600.12(A), (B), or (C).

(C) Class 2.

Where the installation complies with 600.33 and the power source provides a Class 2 output that complies with 600.24, either of the following wiring methods shall be permitted as determined by the installation instructions and conditions.

- Wiring methods identified in Chapter 3

- Class 2 cables complying with Table 600.33(A)(1) and Table 600.33(A)(2)

600.21 Ballasts, Transformers, Electronic Power Supplies, and Class 2 Power Sources.

Ballasts, transformers, electronic power supplies, and Class 2 power sources shall be of the self-contained type or be enclosed by placement in a listed sign body or listed separate enclosure.

(A) Accessibility.

Ballasts, transformers, electronic power supplies, and Class 2 power sources shall be located where accessible and shall be securely fastened in place.

(B) Location.

Ballasts, transformers, electronic power supplies, and Class 2 power sources shall be installed as near to the lamps or neon tubing as practicable to keep the secondary conductors as short as possible.

(C) Wet Location.

Ballasts, transformers, electronic power supplies, and Class 2 power sources used in wet locations shall be of the weatherproof type or be of the outdoor type and protected from the weather by placement in a sign body or separate enclosure.

(D) Working Space.

A working space at least 900 mm (3 ft) high × 900 mm (3 ft) wide × 900 mm (3 ft) deep shall be provided at each ballast, transformer, electronic power supply, and Class 2 power source or at its enclosure where not installed in a sign.

(E) Attic and Soffit Locations.

Ballasts, transformers, electronic power supplies, and Class 2 power sources shall be permitted to be located in attics and soffits, provided there is an access door at least 900 mm × 562.5 mm (36 in. × 221/2 in.) and a passageway of at least 900 mm (3 ft) high × 600 mm (2 ft) wide with a suitable permanent walkway at least 300 mm (12 in.) wide extending from the point of entry to each component. At least one lighting outlet containing a switch or controlled by a wall switch shall be installed in such spaces. At least one point of control shall be at the usual point of entry to these spaces. The lighting outlet shall be provided at or near the equipment requiring servicing.

(F) Suspended Ceilings.

Ballasts, transformers, electronic power supplies, and Class 2 power sources shall be permitted to be located above suspended ceilings, provided that their enclosures are securely fastened in place and not dependent on the suspended-ceiling grid for support. Ballasts, transformers, and electronic power supplies installed in suspended ceilings shall not be connected to the branch circuit by flexible cord.

600.22 Ballasts.

(B) Thermal Protection.

Ballasts shall be thermally protected.

600.23 Transformers and Electronic Power Supplies.

(B) Secondary-Circuit Ground-Fault Protection.

Transformers and electronic power supplies other than the following shall have secondary-circuit ground-fault protection:

- Transformers with isolated ungrounded secondaries and with a maximum open circuit voltage of 7500 volts or less

- Transformers with integral porcelain or glass secondary housing for the neon tubing and requiring no field wiring of the secondary circuit

(C) Voltage.

Secondary-circuit voltage shall not exceed 15,000 volts, nominal, under any load condition. The voltage to ground of any output terminals of the secondary circuit shall not exceed 7500 volts, under any load condition.

(D) Rating.

Transformers and electronic power supplies shall have a secondary-circuit current rating of not more than 300 mA.

(E) Secondary Connections.

Secondary circuit outputs shall not be connected in parallel or in series.

(F) Marking.

Transformers and electronic power supplies that are equipped with secondary-circuit ground-fault protection shall be so marked.

600.24 Class 2 Power Sources.

Class 2 transformers, power supplies, and power sources shall comply with the requirements of Class 2 circuits and 600.24(A), (B), (C), and (D).

(A) Listing.

Class 2 power supplies and power sources shall be listed for use with electric signs and outline lighting systems or shall be a component in a listed electric sign.

(B) Equipment Grounding Conductor.

Metal parts of Class 2 power supplies and power sources shall be connected to the equipment grounding conductor.

600.30 Applicability.

Part II of this article shall apply to all of the following:

- Field-installed skeleton tubing

- Field-installed secondary circuits

- Outline lighting

- Field-installed retrofit kits

These requirements shall be in addition to the requirements of Part I.

600.31 Neon Secondary-Circuit Wiring, 1000 Volts or Less, Nominal.

(A) Wiring Method.

Conductors shall be installed using any wiring method included in Chapter 3 suitable for the conditions.

(B) Insulation and Size.

Conductors shall be listed, insulated, and not smaller than 18 AWG.

(D) Installation.

Conductors shall be installed so they are not subject to physical damage.

600.32 Neon Secondary-Circuit Wiring, Over 1000 Volts, Nominal.

(A) Wiring Methods.

(1) Installation.

Conductors shall be installed in rigid metal conduit, intermediate metal conduit, liquidtight flexible nonmetallic conduit, flexible metal conduit, liquidtight flexible metal conduit, electrical metallic tubing, metal enclosures; on insulators in metal raceways; or in other equipment listed for use with neon secondary circuits over 1000 volts.

(3) Size.

Conduit or tubing shall be a minimum of metric designator 16 (trade size 1/2).

(4) Spacing From Grounded Parts.

(5) Metal Building Parts.

Metal parts of a building shall not be permitted as a secondary return conductor or an equipment grounding conductor.

(B) Insulation and Size.

Conductors shall be insulated, listed as gas tube sign and ignition cable type GTO, rated for 5, 10, or 15 kV, not smaller than 18 AWG, and have a minimum temperature rating of 105°C (221 °F).

(C) Installation.

Conductors shall be so installed that they are not subject to physical damage.

(E) Spacing.

Secondary conductors shall be separated from each other and from all objects other than insulators or neon tubing by a spacing of not less than 38 mm (11/2 in.). GTO cable installed in metal conduit or tubing shall not require spacing between the cable insulation and the conduit or tubing.

(F) Insulators and Bushings.

Insulators and bushings for conductors shall be listed for use with neon secondary circuits over 1000 volts.

(H) Between Neon Tubing and Midpoint Return.

Conductors shall be permitted to run between the ends of neon tubing or to the secondary circuit midpoint return of listed transformers or listed electronic power supplies and provided with terminals or leads at the midpoint.

(J) Length of Secondary Circuit Conductors.

(1) Secondary Conductor to the First Electrode.

The length of secondary circuit conductors from a high-voltage terminal or lead of a transformer or electronic power supply to the first neon tube electrode shall not exceed the following:

(2) Other Secondary Circuit Conductors.

All other sections of secondary circuit conductor in a neon tube circuit shall be as short as practicable.

(K) Splices.

Splices in high-voltage secondary circuit conductors shall be made in listed enclosures rated over 1000 volts. Splice enclosures shall be accessible after installation and listed for the location where they are installed.

600.33 Class 2 Sign Illumination Systems, Secondary Wiring.

The wiring methods and materials used shall be in accordance with the sign manufacturer's installation instructions using any applicable wiring methods from Chapter 3, Wiring Methods, or the requirements for Class 2 circuits contained in 600.12(C), 600.24, and 600.33(A), (B), (C), and (D).

(A) Insulation and Sizing of Class 2 Conductors.

Class 2 cable listed for the application that complies with Table 600.33(A)(1) or Table 600.33(A)(2) for substitutions shall be installed on the load side of the Class 2 power source. The conductors shall have an ampacity not less than the load to be supplied and shall not be sized smaller than 18 AWG.

(1) General Use.

CL2 or CL3, PLTC, or any listed applicable cable for general use shall be installed within and on buildings or structures.

Table 600.33(A)(1) Applications of Power Limited Cable in Signs and Outline Lighting.

| Location | CL2 | CL3 | CL2R | CL3R | CL2P | CL3P | PLTC |

|---|---|---|---|---|---|---|---|

| Nonconcealed spaces inside buildings | Y | Y | Y | Y | Y | Y | Y |

| Concealed spaces inside buildings that are not used as plenums or risers | Y | Y | Y | Y | Y | Y | Y |

| Environmental air spaces plenums | N | N | N | N | Y | Y | N |

| Environmental air spaces risers | N | N | Y | Y | Y | Y | N |

| Wet locations | N | N | N | N | N | N | Y |

Y = Permitted. N = Not Permitted.

(2) Other Building Locations.

In other locations, any listed applicable cable permitted in 600.33(A)(1), (A)(2), (A)(3), and (A)(4) and Table 600.33(A)(1) and Table 600.33(A)(2) shall be permitted to be used as follows:

- CL2P or CL3P - Ducts, plenums, or other spaces used for environmental air

- CL2R or CL3R - Vertical shafts and risers

- Substitutions from Table 600.33(A)(2)

Table 600.33(A)(2) Class 2 Cable Substitutions.

| Cable Type | Permitted Substitutions |

|---|---|

| CL3P | CMP |

| CL2P | CMP, CL3P |

| CL3R | CMP, CL3P, CMR |

| CL2R | CMP, CL3P, CL2P, CMR, CL3R |

| CL3 | CMP, CL3P, CMR, CL3R, CMG, CM, PLTC |

| CL2 | CMP, CL3P, CL2P, CMR, CL3R, CL2R, CMG, CM, PLTC, CL3 |

| CLX | CMP, CL3P, CMR, CL3R, CMG, CM, PLTC, CL3, CMX |

| CL2X | CMP, CL3P, CL2P, CMR, CL3R, CL2R, CMG, CM, PLTC, CL3, CL2, CMX, CL3X |

| PLTC | None |

(B) Installation.

Secondary wiring shall be installed in accordance with 600.33(B)(1) and (B)(2).

- Wiring shall be installed and supported in a neat and workmanlike manner. Cables and conductors installed exposed on the surface of ceilings and sidewalls shall be supported by the building structure in such a manner that the cable is not damaged by normal building use. The cable shall be supported and secured at intervals not exceeding 1.8 m (6 ft). Such cables shall be supported by straps, staples, hangers, cable ties, or similar fittings designed and installed so as not to damage the cable. The installation shall also comply with 300.4(D).

- Connections in cable and conductors shall be made with listed insulating devices and be accessible after installation. Where made in a wall, connections shall be enclosed in a listed box.

(C) Protection Against Physical Damage.

If subject to physical damage, the conductors shall be protected and installed in accordance with 300.4. All through-wall penetrations shall be protected by a listed bushing or raceway.

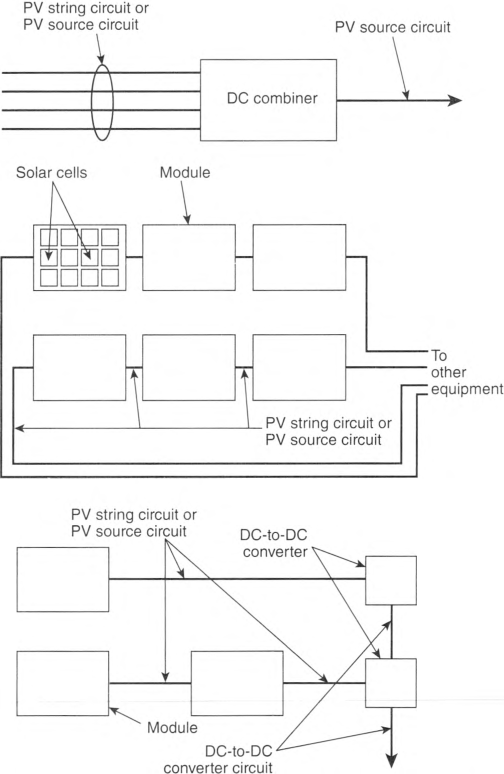

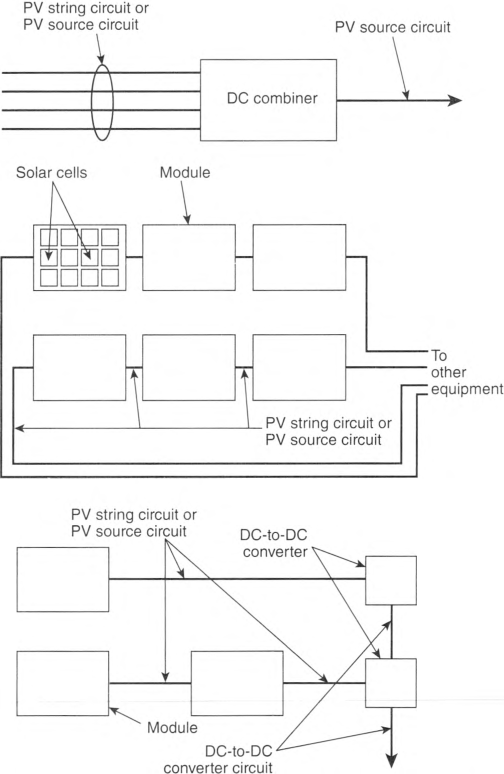

600.34 Photovoltaic (PV) Powered Sign.

All field wiring of components and subassemblies for an off-grid stand-alone, on-grid interactive, or non-grid interactive PV installation shall be installed in accordance with Article 690, as applicable, 600.34, and the PV powered sign installation instructions.

(A) Equipment.

Inverters, motor generators, PV modules, PV panels, ac PV modules, dc combiners, dc-ac converters, and charge controllers intended for use in PV powered sign systems shall be listed for PV application.

(B) Wiring.

(C) Flexible Cords and Cables.

Flexible cords and cables shall comply with Article 400 and be identified as extra hard usage, rated for outdoor use, and water and sunlight resistant.

(F) Battery Compartments.

Battery compartments shall require a tool to open.

600.35 Retrofit Kits.

(A) General.

A general-use or sign-specific retrofit kit for a sign or outline lighting system shall include installation instructions and requirements for field conversion of a host sign. The retrofit kit shall be listed and labeled.

(B) Damaged Parts.

All parts that are not replaced by a retrofit kit shall be inspected for damage. Any part found to be damaged or damaged during conversion of the sign shall be replaced or repaired to maintain the sign or outline lighting system's dry, damp, or wet location rating.

600.41 Neon Tubing.

(A) Design.

The length and design of the tubing shall not cause a continuous overcurrent beyond the design loading of the transformer or electronic power supply.

(B) Support.

Tubing shall be supported by listed tube supports. The neon tubing shall be supported within 150 mm (6 in.) from the electrode connection.

(C) Spacing.

A spacing of not less than 6 mm (1/4 in.) shall be maintained between the tubing and the nearest surface, other than its support.

(D) Protection.

Field-installed skeleton tubing shall not be subject to physical damage. Where the tubing is readily accessible to other than qualified persons, field-installed skeleton tubing shall be provided with suitable guards or protected by other approved means.

600.42 Electrode Connections.

(B) Accessibility.

Terminals of the electrode shall not be accessible to unqualified persons.

(C) Electrode Connections.

Connections shall be made by use of a connection device, twisting of the wires together, or use of an electrode receptacle. Connections shall be electrically and mechanically secure and shall be in an enclosure listed for the purpose.

(D) Support.

Neon secondary conductor(s) shall be supported not more than 150 mm (6 in.) from the electrode connection to the tubing.

(F) Bushings.

Where electrodes penetrate an enclosure, bushings listed for the purpose shall be used unless receptacles are provided.

(G) Wet Locations.

A listed cap shall be used to close the opening between neon tubing and a receptacle where the receptacle penetrates a building. Where a bushing or neon tubing penetrates a building, the opening between neon tubing and the bushing shall be sealed.

(H) Electrode Enclosures.

(1) Dry Locations.

Electrode enclosures that are listed, labeled, and identified for use in dry, damp, or wet locations shall be permitted to be installed and used in such locations.

(2) Damp and Wet Locations.

Electrode enclosures installed in damp and wet locations shall be specifically listed, labeled, and identified for use in such locations.

Article 604

Manufactured Wiring Systems

604.1 Scope.

This article applies to field-installed wiring using off-site manufactured subassemblies for branch circuits, remote-control circuits, signaling circuits, and communications circuits in accessible areas.

604.6 Listing Requirements.

Manufactured wiring systems and associated components shall be listed.

Informational Note: See ANSI/UL 183, Standard for Manufacturing Wiring Systems, the safety standard for manufactured wiring systems.

604.7 Installation.

Manufactured wiring systems shall be secured and supported in accordance with the applicable cable or conduit article for the cable or conduit type employed.

604.10 Uses Permitted.

Manufactured wiring systems shall be permitted in accessible and dry locations and in ducts, plenums, and other air-handling spaces where listed for this application and installed in accordance with 300.22.

Exception No. 1: In concealed spaces, one end of tapped cable shall be permitted to extend into hollow walls for direct termination at switch and outlet points.

Exception No. 2: Manufactured wiring system assemblies installed outdoors shall be listed for use in outdoor locations.

604.12 Uses Not Permitted.

Manufactured wiring system types shall not be permitted where limited by the applicable article in Chapter 3 for the wiring method used in its construction.

604.100 Construction.

(A) Cable, Conduit, and Tubing Types.

(1) Cables.

Cable shall be listed Type AC cable or listed Type MC cable containing nominal 600-volt, 8 AWG to 12 AWG insulated copper-clad aluminum or copper conductors.

(2) Conduits and Tubing.

Conduit shall be listed flexible metal conduit (FMC), listed liquidtight flexible metal conduit (LFMC), liquidtight flexible nonmetallic conduit (LFNC), or electrical metallic tubing (EMT) containing nominal 600-volt, 8 AWG to 12 AWG insulated copper-clad aluminum or copper conductors with a bare or insulated copper-clad aluminum or copper equipment grounding conductor equivalent in size to the ungrounded conductor.

Exception No. 1 to (1) and (2): A luminaire tap, no longer than 1.8 m (6 ft) and intended for connection to a single luminaire, shall be permitted to contain conductors smaller than 12 AWG but not smaller than 18 AWG.

Exception No. 2 to (1) and (2): Listed manufactured wiring assemblies containing conductors smaller than 12 AWG shall be permitted for remote-control, signaling, or communications circuits.

Exception No. 3 to (2): Listed manufactured wiring systems containing unlisted flexible metal conduit of noncircular cross section or trade sizes smaller than permitted by 348.20(A), or both, shall be permitted where the wiring systems are supplied with fittings and conductors at the time of manufacture.

(3) Flexible Cord.

Flexible cord suitable for hard usage, with minimum 12 AWG conductors, shall be permitted as part of a listed factory-made assembly not exceeding 1.8 m (6 ft) in length when making a transition between components of a manufactured wiring system and utilization equipment not permanently secured to the building structure. The cord shall be visible for the entire length, shall not be subject to physical damage, and shall be provided with identified strain relief.

Exception: Listed electric-discharge luminaires that comply with 410.62(C) shall be permitted with conductors smaller than 12 AWG.

(4) Busways.

Busways shall be listed continuous plug-in type containing factory-mounted, bare or insulated conductors, which shall be copper or aluminum bars, rods, or tubes. The busway shall be provided with an equipment ground. The busway shall be rated nominal 600 volts, 20, 30, or 40 amperes. Busways shall be installed in accordance with 368.12, 368.17(D), and 368.30.

(C) Receptacles and Connectors.

Receptacles and connectors shall be of the locking type, uniquely polarized and identified for the purpose, and shall be part of a listed assembly for the appropriate system. All connector openings shall be designed to prevent inadvertent contact with live parts or capped to effectively close the connector openings.

(D) Other Component Parts.

Other component parts shall be listed for the appropriate system.

Article 605

Office Furnishings

605.1 Scope.

(A) Covered.

This article covers electrical equipment, lighting accessories, and wiring systems used to connect, contained within, or installed on office furnishings.

(B) Not Covered.

This article does not apply to individual office furnishings not connected to a system, such as chairs, freestanding desks, tables, storage units, and shelving units.

605.3 General.

Wiring systems shall be identified as suitable for providing power for lighting accessories and utilization equipment used within office furnishings. A wired partition shall not extend from floor to ceiling.

Exception: Where permitted by the authority having jurisdiction, these relocatable wired partitions shall be permitted to extend to, but shall not penetrate, the ceiling.

605.4 Wireways.

All conductors and connections shall be contained within wiring channels of metal or other material identified as suitable for the conditions of use. Wiring channels shall be free of projections or other conditions that might damage conductor insulation.

605.5 Office Furnishing Interconnections.

The electrical connection between office furnishings shall be a flexible assembly identified for use with office furnishings or shall be permitted to be installed using flexible cord, provided that all the following conditions are met:

- The cord is extra-hard usage type with 12 AWG or larger conductors, with an insulated equipment grounding conductor.

- The office furnishings are mechanically contiguous.

- The cord is not longer than necessary for maximum positioning of the office furnishing but is in no case to exceed 600 mm (2 ft).

- The cord is terminated at an attachment plug-and-cord connector with strain relief.

605.6 Lighting Accessories.

Lighting equipment shall be listed, labeled, and identified for use with office furnishings and shall comply with 605.6(A), (B), and (C).

(A) Support.

A means for secure attachment or support shall be provided.

(B) Connection.

Where cord and plug connection is provided, it shall comply with all of the following:

- The cord length shall be suitable for the intended application but shall not exceed 2.7 m (9 ft) in length.

- The cord shall not be smaller than 18 AWG.

- The cord shall contain an equipment grounding conductor, except as specified in 605.6(B)(4).

- Cords on the load side of a listed Class 2 power source shall not be required to contain an equipment grounding conductor.

- The cord shall be of the hard usage type, except as specified in 605.6(B)(6).

- A cord provided on a listed Class 2 power source shall be of the type provided with the listed luminaire assembly or of the type specified in 725.130 and 725.127.

- Connection by other means shall be identified as suitable for the conditions of use.

(C) Receptacle Outlet.

Receptacles shall not be permitted in lighting accessories.

605.7 Fixed-Type Office Furnishings.

Office furnishings that are fixed (secured to building surfaces) shall be permanently connected to the building electrical system by one of the wiring methods of Chapter 3.

605.8 Freestanding-Type Office Furnishings.

Office furnishings of the freestanding type (not fixed) shall be permitted to be connected to the building electrical system by one of the wiring methods of Chapter 3.

605.9 Freestanding-Type Office Furnishings, Cord- And Plug-Connected.

Individual office furnishings of the freestanding type, or groups of individual office furnishings that are electrically connected, are mechanically contiguous, and do not exceed 9.0 m (30 ft) when assembled, shall be permitted to be connected to the building electrical system by a single flexible cord and plug, provided that all of the conditions of 605.9(A) through (D) are met.

(A) Flexible Power-Supply Cord.

The flexible power supply cord shall be extra-hard usage type with 12 AWG or larger conductors, with an insulated equipment grounding conductor, and shall not exceed 600 mm (2 ft) in length.

(B) Receptacle Supplying Power.

The receptacle(s) supplying power shall be on a separate circuit serving only the office furnishing and no other loads and shall be located not more than 300 mm (12 in.) from the office furnishing that is connected to it.

(C) Receptacle. Maximum.

An individual office furnishing or groups of interconnected individual office furnishings shall not contain more than 13 15-ampere, 125-volt receptacles. For purposes of this requirement, a receptacle is considered (1) up to two (simplex) receptacles provided within a single enclosure and that are within 0.3 m (1 ft) of each other or (2) one duplex receptacle.

(D) Multiwire Circuits, Not Permitted.

An individual office furnishing or groups of interconnected office furnishings shall not contain multiwire circuits.

Article 610

Cranes and Hoists

610.3 Special Requirements for Particular Locations.

(A) Hazardous (Classified) Locations.

(1) Class I Locations.

Equipment used in locations that are hazardous because of the presence of flammable gases or vapors shall conform to Article 501.

(2) Class II Locations.

Equipment used in locations that are hazardous because of combustible dust shall conform to Article 502.

(3) Class III Locations.

Equipment used in locations that are hazardous because of the presence of easily ignitible fibers or flyings shall conform to Article 503.

(B) Combustible Materials.

Where a crane, hoist, or monorail hoist operates over readily combustible material, the resistors shall be located as permitted in the following:

- A well ventilated cabinet composed of noncombustible material constructed so that it does not emit flames or molten metal

- A cage or cab constructed of noncombustible material that encloses the sides of the cage or cab from the floor to a point at least 150 mm (6 in.) above the top of the resistors

610.11 Wiring Method.

Conductors shall be enclosed in raceways or be Type AC cable with insulated equipment grounding conductor, Type MC cable, or Type MI cable unless otherwise permitted or required in 610.11 (A) through (E).

(C) Flexible Connections to Motors and Similar Equipment.

Where flexible connections are necessary, flexible stranded conductors shall be used. Conductors shall be in flexible metal conduit, liquidtight flexible metal conduit, liquidtight flexible nonmetallic conduit, multiconductor cable, or an approved nonmetallic flexible raceway.

(D) Pushbutton Station Multiconductor Cable.

Where multiconductor cable is used with a suspended pushbutton station, the station shall be supported in some satisfactory manner that protects the electrical conductors against strain.

(E) Flexibility to Moving Parts.

610.12 Raceway or Cable Terminal Fittings.

(B) Bushing in Lieu of a Box.

A bushing shall be permitted to be used in lieu of a box at the end of a rigid metal conduit, intermediate metal conduit, or electrical metallic tubing where the raceway terminates at unenclosed controls or similar equipment, including contact conductors, collectors, resistors, brakes, power-circuit limit switches, and dc split-frame motors.

610.13 Types of Conductors.

Conductors shall comply with Table 310.4(1) unless otherwise permitted in 610.13(A) through (C).

(A) Exposed to External Heat or Connected to Resistors.

A conductor(s) exposed to external heat or connected to resistors shall have a flame-resistant outer covering or be covered with flame-resistant tape individually or as a group.

610.14 Rating and Size of Conductors.

(A) Ampacity.

(B) Secondary Resistor Conductors.

Where the secondary resistor is separate from the controller, the minimum size of the conductors between controller and resistor shall be calculated by multiplying the motor secondary current by the appropriate factor from Table 610.14(B) and selecting a wire from Table 610.14(A).

(C) Minimum Size.

Conductors external to motors and controls shall be not smaller than 16 AWG unless otherwise permitted in either of the following:

- 18 AWG wire in multiconductor cord shall be permitted for control circuits not exceeding 7 amperes.

- Wires not smaller than 20 AWG shall be permitted for electronic circuits.

(E) Calculation of Motor Load.

(1) Single Motor.

For one motor, 100 percent of motor nameplate full-load ampere rating shall be used.

(2) Multiple Motors on Single Crane or Hoist.

For multiple motors on a single crane or hoist, the minimum ampacity of the power supply conductors shall be the nameplate full-load ampere rating of the largest motor or group of motors for any single crane motion, plus 50 percent of the nameplate full-load ampere rating of the next largest motor or group of motors, using that column of Table 610.14(A) that applies to the longest time-rated motor.

(3) Multiple Cranes or Hoists on a Common Conductor System.

For multiple cranes, hoists, or both, supplied by a common conductor system, calculate the motor minimum ampacity shall be calculated for each crane as defined in 610.14(E), added them together, and the sum multiplied by the appropriate demand factor from Table 610.14(E)(3).

(F) Other Loads.

Additional loads, such as heating, lighting, and air conditioning, shall be provided for by application of the appropriate sections of this Code.

(G) Nameplate.

Each crane, monorail, or hoist shall be provided with a visible nameplate marked with the manufacturer's name, rating in volts, frequency, number of phases, and circuit amperes as calculated in 610.14(E) and (F).

Table 610.14(A) Ampacities of Insulated Copper Conductors Used with Short-Time Rated Crane and Hoist Motors. Based on Ambient Temperature of 30°C (86°F).

| Maximum Operating Temperature | Up to Four Simultaneously Energized Conductors in Raceway or Cable1 | Up to Three ac2 or Four dc1 Simultaneously Energized Conductors in Raceway or Cable | Maximum Operating Temperature | ||||

|---|---|---|---|---|---|---|---|

| 75°C (167°F) | 90°C (194°F) | 125°C (257°F) | |||||

| Size (AWG or kcmil) | Types MTW, RHW, THW, THWN, XHHW, USE, ZW | Types TA, TBS, SA, SIS, PFA, FEP, FEPB, RHH, THHN, XHHW, Z, ZW | Types FEP, FEPB, PFA, PFAH, SA, TFE, Z, ZW | Size (AWG or kcmil) | |||

| 60 Min | 30 Min | 60 Min | 30 Min | 60 Min | 30 Min | ||

| 16 | 10 | 12 | - | - | - | - | 16 |

| 14 | 25 | 26 | 31 | 32 | 38 | 40 | 14 |

| 12 | 30 | 33 | 36 | 40 | 45 | 50 | 12 |

| 10 | 40 | 43 | 49 | 52 | 60 | 65 | 10 |

| 8 | 55 | 60 | 63 | 69 | 73 | 80 | 8 |

| 6 | 76 | 86 | 83 | 94 | 101 | 119 | 6 |

| 5 | 85 | 95 | 95 | 106 | 115 | 134 | 5 |

| 4 | 100 | 117 | 111 | 130 | 133 | 157 | 4 |

| 3 | 120 | 141 | 131 | 153 | 153 | 183 | 3 |

| 2 | 137 | 160 | 148 | 173 | 178 | 214 | 2 |

| 1 | 143 | 175 | 158 | 192 | 210 | 253 | 1 |

| 1/0 | 190 | 233 | 211 | 259 | 253 | 304 | 1/0 |

| 2/0 | 222 | 267 | 245 | 294 | 303 | 369 | 2/0 |

| 3/0 | 280 | 341 | 305 | 372 | 370 | 452 | 3/0 |

| 4/0 | 300 | 369 | 319 | 399 | 451 | 555 | 4/0 |

| 250 | 364 | 420 | 400 | 461 | 510 | 635 | 250 |

| 300 | 455 | 582 | 497 | 636 | 587 | 737 | 300 |

| 350 | 486 | 646 | 542 | 716 | 663 | 837 | 350 |

| 400 | 538 | 688 | 593 | 760 | 742 | 941 | 400 |

| 450 | 600 | 765 | 660 | 836 | 818 | 1042 | 450 |

| 500 | 660 | 847 | 726 | 914 | 896 | 1143 | 500 |

| AMPACITY CORRECTION FACTORS | |||||||

| Ambient Temperature (°C) | For ambient temperatures other than 30°C (86°F), multiply the ampacities shown above by the appropriate factor shown below. | Ambient Temperature (°F) | |||||

| 21—25 | 1.05 | 1.05 | 1.04 | 1.04 | 1.02 | 1.02 | 70—77 |

| 26—30 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 79—86 |

| 31—35 | 0.94 | 0.94 | 0.96 | 0.96 | 0.97 | 0.97 | 88—95 |

| 36—40 | 0.88 | 0.88 | 0.91 | 0.91 | 0.95 | 0.95 | 97—104 |

| 41—45 | 0.82 | 0.82 | 0.87 | 0.87 | 0.92 | 0.92 | 106—113 |

| 46—50 | 0.75 | 0.75 | 0.82 | 0.82 | 0.89 | 0.89 | 115—122 |

| 51—55 | 0.67 | 0.67 | 0.76 | 0.76 | 0.86 | 0.86 | 124—131 |

| 56—60 | 0.58 | 0.58 | 0.71 | 0.71 | 0.83 | 0.83 | 133—140 |

| 61—70 | 0.33 | 0.33 | 0.58 | 0.58 | 0.76 | 0.76 | 142—158 |

| 71—80 | - | - | 0.41 | 0.41 | 0.69 | 0.69 | 160—176 |

| 81—90 | - | - | - | - | 0.61 | 0.61 | 177—194 |

| 91—100 | - | - | - | - | 0.51 | 0.51 | 195—212 |

| 101—120 | - | - | - | - | 0.40 | 0.40 | 213—248 |

Note: Other insulations shown in Table 310.4(1) and approved for the temperature and location shall be permitted to be substituted for those shown in Table 610.14(A). The allowable ampacities of conductors used with 15-minute motors shall be the 30-minute ratings increased by 12 percent.

Table 610.14(D) Minimum Contact Conductor Size Based on Distance Between Supports.

| Minimum Size of Wire (AWG) | Maximum Distance Between End Strain Insulators or Clamp-Type Intermediate Supports |

|---|---|

| 6 | 9.0 m (30 ft) or less |

| 4 | 18 m (60 ft) or less |

| 2 | Over 18 m (60 ft) |

Table 610.14(E)(3) Demand Factors.

| Number of Cranes or Hoists | Demand Factor |

|---|---|

| 2 | 0.95 |

| 3 | 0.91 |

| 4 | 0.87 |

| 5 | 0.84 |

| 6 | 0.81 |

| 7 | 0.78 |

610.21 Installation of Contact Conductors.

(A) Locating or Guarding Contact Conductors.

Runway contact conductors shall be guarded, and bridge contact conductors shall be located or guarded in such a manner that persons cannot inadvertently touch energized current-carrying parts.

(C) Supports Along Runways.

Main contact conductors carried along runways shall be supported on insulating supports placed at intervals not exceeding 6.0 m (20 ft) unless otherwise permitted in 610.21 (F).

Such conductors shall be separated at not less than 150 mm (6 in.), other than for monorail hoists where a spacing of not less than 75 mm (3 in.) shall be permitted. Where necessary, intervals between insulating supports shall be permitted to be increased up to 12 m (40 ft), the separation between conductors being increased proportionately.

(D) Supports on Bridges.

Bridge wire contact conductors shall be kept at least 65 mm (21/2 in.) apart, and, where the span exceeds 25 m (80 ft), insulating saddles shall be placed at intervals not exceeding 15 m (50 ft).

(E) Supports for Rigid Conductors.

Conductors along runways and crane bridges, that are of the rigid type specified in 610.13(B) and not contained within an approved enclosed assembly, shall be carried on insulating supports spaced at intervals of not more than 80 times the vertical dimension of the conductor, but in no case greater than 4.5 m (15 ft), and spaced apart sufficiently to give a clear electrical separation of conductors or adjacent collectors of not less than 25 mm (1 in.).

(F) Track as Circuit Conductor.

Monorail, tram rail, or crane runway tracks shall be permitted as a conductor of current for one phase of a 3-phase, ac system furnishing power to the carrier, crane, or trolley, provided all of the following conditions are met:

- The conductors supplying the other two phases of the power supply are insulated.

- The power for all phases is obtained from an insulating transformer.

- The voltage does not exceed 300 volts.

- The rail serving as a conductor shall be bonded to the equipment grounding conductor at the transformer and also shall be permitted to be grounded by the fittings used for the suspension or attachment of the rail to a building or structure.

(G) Electrical Continuity of Contact Conductors.

All sections of contact conductors shall be mechanically joined to provide a continuous electrical connection.

610.22 Collectors.

Collectors shall be designed so as to reduce to a minimum sparking between them and the contact conductor; and, where operated in rooms used for the storage of easily ignitible combustible fibers and materials, they shall comply with 503.155.

610.31 Runway Conductor Disconnecting Means.

A disconnecting means that has a continuous ampere rating not less than that calculated in 610.14(E) and (F) shall be provided between the runway contact conductors and the power supply. The disconnecting means shall comply with 430.109. This disconnecting means shall be as follows:

- Readily accessible and operable from the ground or floor level

- Lockable open in accordance with 110.25

- Open all ungrounded conductors simultaneously

- Placed within view of the runway contact conductors

Exception: The runway conductor disconnecting means for electrolytic cell lines shall be permitted to be placed out of view of the runway contact conductors where either of the following conditions are met:

- Where a location in view of the contact conductors is impracticable or introduces additional or increased hazards to persons or property

- In industrial installations, with written safety procedures, where conditions of maintenance and supervision ensure that only qualified persons service the equipment

610.32 Disconnecting Means for Cranes and Monorail Hoists.

A disconnecting means in compliance with 430.109 shall be provided in the leads from the runway contact conductors or other power supply on all cranes and monorail hoists. The disconnecting means shall be lockable open in accordance with 110.25.

Where a monorail hoist or hand-propelled crane bridge installation meets all of the following, the disconnecting means shall be permitted to be omitted:

- The unit is controlled from the ground or floor level.

- The unit is within view of the power supply disconnecting means.

- No fixed work platform has been provided for servicing the unit.

610.33 Rating of Disconnecting Means.

The continuous ampere rating of the switch or circuit breaker required by 610.32 shall not be less than 50 percent of the combined short-time ampere rating of the motors or less than 75 percent of the sum of the short-time ampere rating of the motors required for any single motion.

610.41 Feeders, Runway Conductors.

(A) Single Feeder.

The runway supply conductors and main contact conductors of a crane or monorail shall be protected by an overcurrent device(s) that shall not be greater than the largest rating or setting of any branch-circuit protective device plus the sum of the nameplate ratings of all the other loads with application of the demand factors from Table 610.14(E)(3).

(B) More Than One Feeder Circuit.

Where more than one feeder circuit is installed to supply runway conductors, each feeder circuit shall be sized and protected in compliance with 610.41(A).

610.42 Branch-Circuit Short-Circuit and Ground-Fault Protection.

Branch circuits shall be protected in accordance with 610.42(A). Branch-circuit taps, where made, shall comply with 610.42(B).

(A) Fuse or Circuit Breaker Rating.

Crane, hoist, and mono-rail hoist motor branch circuits shall be protected by fuses or inverse-time circuit breakers that have a rating in accordance with Table 430.52(C)(1). Where two or more motors operate a single motion, the sum of their nameplate current ratings shall be considered as that of a single motor.

(B) Taps.

(1) Multiple Motors.

Where two or more motors are connected to the same branch circuit, each tap conductor to an individual motor shall have an ampacity not less than one-third that of the branch circuit. Each motor shall be protected from overload according to 610.43.

(2) Control Circuits.

Where taps to control circuits originate on the load side of a branch-circuit protective device, each tap and piece of equipment shall be protected in accordance with 430.72.

610.43 Overload Protection.

(A) Motor and Branch-Circuit Overload Protection.

Each motor, motor controller, and branch-circuit conductor shall be protected from overload by one of the following means:

- A single motor shall be considered as protected where the branch-circuit overcurrent device meets the rating requirements of 610.42.

- Overload relay elements in each ungrounded circuit conductor, with all relay elements protected from short circuit by the branch-circuit protection.

- Thermal sensing devices, sensitive to motor temperature or to temperature and current, that are thermally in contact with the motor winding(s). Hoist functions shall be considered to be protected if the sensing device limits the hoist to lowering only during an overload condition. Traverse functions shall be considered to be protected if the sensing device limits the travel in both directions for the affected function during an overload condition of either motor.

(C) Multimotor.

Where two or more motors drive a single trolley, truck, or bridge and are controlled as a unit and protected by a single set of overload devices with a rating equal to the sum of their rated full-load currents, a hoist or trolley shall be considered to be protected if the sensing device is connected in the hoist's upper limit switch circuit so as to prevent further hoisting during an overtemperature condition of either motor.

610.51 Separate Controllers.

Each motor shall be provided with an individual controller unless otherwise permitted in 610.51(A) or (B).

(A) Motions With More Than One Motor.

Where two or more motors drive a single hoist, carriage, truck, or bridge, they shall be permitted to be controlled by a single controller.

(B) Multiple Motion Controller.

One controller shall be permitted to be switched between motors, under the following conditions:

- The controller has a horsepower rating that is not lower than the horsepower rating of the largest motor.

- Only one motor is operated at one time.

610.53 Overcurrent Protection.

Conductors of control circuits shall be protected against overcurrent. Control circuits shall be considered as protected by overcurrent devices that are rated or set at not more than 300 percent of the ampacity of the control conductors, unless otherwise permitted in 610.53(A) or (B).

(A) Taps to Control Transformers.

Taps to control transformers shall be considered as protected where the secondary circuit is protected by a device rated or set at not more than 200 percent of the rated secondary current of the transformer and not more than 200 percent of the ampacity of the control circuit conductors.

(B) Continuity of Power.

Where the opening of the control circuit would create a hazard, as for example, the control circuit of a hot metal crane, the control circuit conductors shall be considered as being properly protected by the branch-circuit overcurrent devices.

610.57 Clearance.

The dimension of the working space in the direction of access to live parts that are likely to require examination, adjustment, servicing, or maintenance while energized shall be a minimum of 750 mm (21/2 ft). Where controls are enclosed in cabinets, the door(s) shall either open at least 90 degrees or be removable.

610.61 Grounding and Bonding.

All exposed non-current-carrying metal parts of cranes, monorail hoists, hoists, and accessories, including pendant controls, shall be bonded either by mechanical connections or bonding jumpers, where applicable, so that the entire crane or hoist is an effective ground-fault current path by connection to the equipment grounding conductor of the branch circuit or feeder as required or permitted by Article 250, Parts I, V, VI, and VII.

Moving parts, other than removable accessories, or attachments that have metal-to-metal bearing surfaces, shall be considered to be electrically bonded to each other through bearing surfaces for the purpose of establishing an effective ground-fault current path. The trolley frame and bridge frame shall not be considered as electrically bonded through the bridge and trolley wheels and its respective tracks. A separate bonding conductor shall be provided.

Article 620

Elevators, Dumbwaiters, Escalators, Moving Walks, Platform Lifts, and Stairway Chairlifts

620.1 Scope.

This article covers the installation of electrical equipment and wiring used in connection with elevators, dumbwaiters, escalators, moving walks, platform lifts, and stairway chairlifts.

Informational Note No. 1: See ASME A17.1/CSA B44, Safety Code for Elevators and Escalators, for information on the installation of elevators and escalators.

Informational Note No. 2: See CSA B44.1/ASME A17.5, Elevator and escalator electrical equipment, for information on elevator and escalator electrical equipment.

Informational Note No. 3: See ASME A18.1, Safety Standard for Platform Lifts and Stairway Chairlifts, for information on installation of platform lifts and stairway chairlifts. The term wheelchair lift has been changed to platform lift.

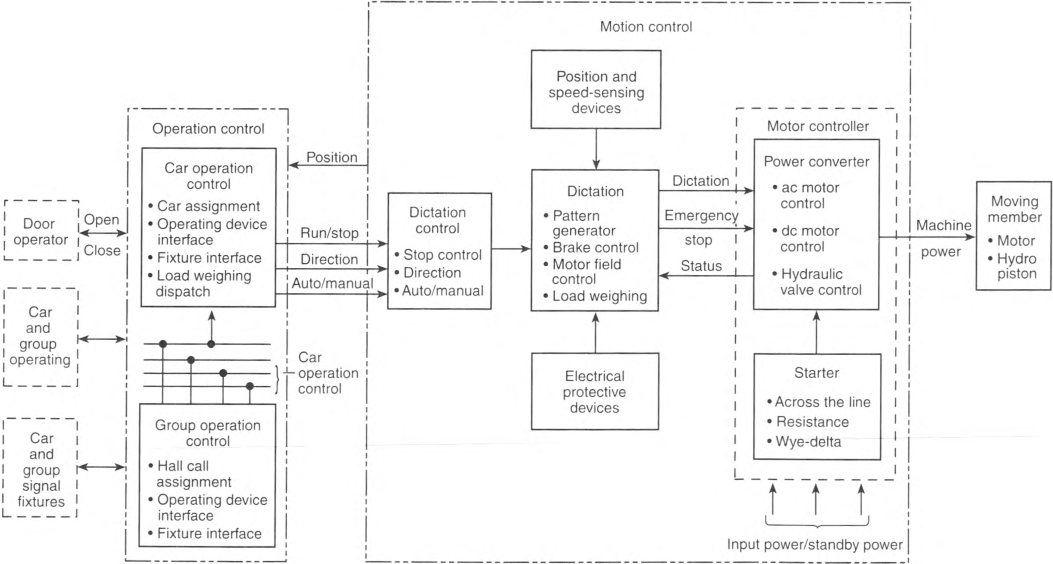

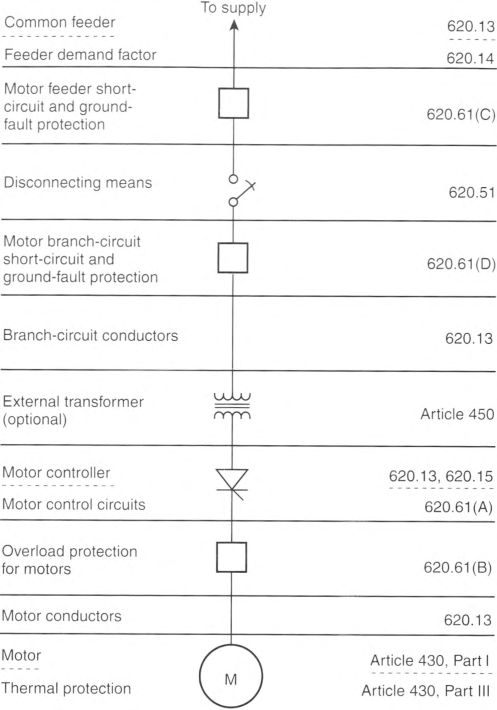

Informational Note No. 4: The motor controller, motion controller, and operation controller are located in a single enclosure or a combination of enclosures.

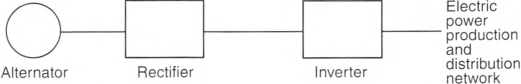

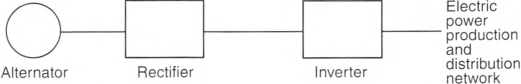

Informational Note No. 5: See Informational Note Figure 620.1 for information only.

Informational Note Figure 620.1 Control System.

620.3 Voltage Limitations.

The supply voltage shall not exceed 300 volts between conductors unless otherwise permitted in 620.3(A) through (C).

(A) Power Circuits.

Branch circuits to door operator controllers and door motors and branch circuits and feeders to motor controllers, driving machine motors, machine brakes, and motor-generator sets shall not have a circuit voltage in excess of 1000 volts. Internal voltages of power conversion equipment and functionally associated equipment, and the operating voltages of wiring interconnecting the equipment, shall be permitted to be higher, provided that all such equipment and wiring shall be listed for the higher voltages. Where the voltage exceeds 600 volts, warning labels or signs that read "DANGER - HIGH VOLTAGE" shall be attached to the equipment and shall be plainly visible. The danger sign(s) or label(s) shall comply with 110.21(B).

620.4 Live Parts Enclosed.

All live parts of electrical apparatus in the hoistways, at the landings, in or on the cars of elevators and dumbwaiters, in the wellways or the landings of escalators or moving walks, or in the runways and machinery spaces of platform lifts and stairway chairlifts shall be enclosed to protect against accidental contact.

Informational Note: See 110.27 for guarding of live parts (1000 volts, nominal, or less).

620.5 Working Clearances.

Working space shall be provided about controllers, disconnecting means, and other electrical equipment in accordance with 110.26(A).

(A) Flexible Connections to Equipment.

Electrical equipment in the following is provided with flexible leads to all external connections so that it can be repositioned to meet the clear working space requirements of 110.26:

- Controllers and disconnecting means for dumbwaiters, escalators, moving walks, platform lifts, and stairway chair-lifts installed in the same space with the driving machine

- Controllers and disconnecting means for elevators installed in the hoistway or on the car

- Controllers for door operators

- Other electrical equipment installed in the hoistway or on the car

(B) Guards.

Live parts of the electrical equipment are suitably guarded, isolated, or insulated to reduce the likelihood of inadvertent contact with live parts operating at voltages greater than 30 volts ac rms, 42 volts ac peak, or 60 volts dc, and the equipment can be examined, adjusted, serviced, or maintained while energized without removal of this protection.

620.6 Ground-Fault Circuit-Interrupter Protection for Personnel.

(A) Pits, Hoistways, and on Cars.

Each 125-volt, single-phase, 15- and 20-ampere receptacle installed in pits, in hoistways, on the cars of elevators and dumbwaiters associated with wind turbine tower elevators, on the platforms or in the runways and machinery spaces of platform lifts and stairway chairlifts, and in escalator and moving walk wellways shall be a listed Class A ground-fault circuit-interrupter type.

(B) Machine Rooms, Control Spaces, Machinery Spaces, Control Rooms, and Truss Interiors.

All 125-volt, single-phase, 15- and 20-ampere receptacles installed in machine rooms, control spaces, machinery spaces, control rooms, and truss interiors shall have listed Class A ground-fault circuit-interrupter protection for personnel.

(C) Sump Pumps.

A permanently installed sump pump shall be permanently wired or shall be supplied by a receptacle that is protected by a listed Class A ground-fault circuit-interrupter.

620.11 Insulation of Conductors.

The insulation of conductors shall comply with 620.11(A) through (D).

Informational Note: See UL 2556-2015, Wire and Cable Test Methods, for one method of determining that the insulation of conductors is flame retardant by testing the conductors or cables to the FV-2/VW-1 Test.

(A) Hoistway Door Interlock Wiring.

The conductors to the hoistway door interlocks from the hoistway riser shall be one of the following:

- Flame retardant and suitable for a temperature of not less than 200°C (392°F). Conductors shall be Type SF or equivalent.

- Physically protected using an approved method, such that the conductor assembly is flame retardant and suitable for a temperature of not less than 200°C (392°F).

(C) Other Wiring.

All conductors in raceways shall have flame retardant insulation.

Conductors shall be Type MTW, TF, TFF, TFN, TFFN, THHN, THW, THWN, TW, XHHW, hoistway cable, or any other conductor with insulation designated as flame retardant. Shielded conductors shall be permitted if such conductors are insulated for the maximum nominal circuit voltage applied to any conductor within the cable or raceway system.

620.12 Minimum Size of Conductors.

The minimum size of conductors, other than conductors that form an integral part of control equipment, shall be in accordance with 620.12(A) and (B).

(A) Traveling Cables.

(1) Lighting Circuits.

For lighting circuits, 14 AWG copper, 20 AWG copper or larger conductors shall be permitted in parallel, provided the ampacity is equivalent to at least that of 14 AWG copper.

(2) Class 2 and Communications Circuits.

Communications cables used for Class 2 or communications circuits shall have a current limit equal to or greater than the current required to power the powered Class 2 or communications device. Communications cables shall comply with 800.179. The minimum conductor size for communications circuits shall be 24 AWG.

(4) Paralleled Conductors.

Where ampacity requirements or voltage drop conditions in a traveling cable circuit prevent the use of a single conductor of AWG 14 or smaller, conductors shall be permitted in parallel in compliance with all the following:

- Each conductor shall be no smaller than 20 AWG copper.

- The paralleled conductors shall be the same type and have the same ampacity rating.

- No more than 3 conductors shall be paralleled.

- The overcurrent protection shall be such that the ampacity of each individual conductor will not be exceeded if one of the parallel conductors becomes inadvertently disconnected.

(B) Other Wiring.

24 AWG copper. Smaller size listed conductors shall be permitted.

620.13 Feeder and Branch-Circuit Conductors.

Conductors shall have an ampacity in accordance with 620.13(A) through (D). With generator field control, the conductor ampacity shall be based on the nameplate current rating of the driving motor of the motor-generator set that supplies power to the elevator motor.

Informational Note No. 1: The heating of conductors depends on root-mean-square current values, which, with generator field control, are reflected by the nameplate current rating of the motor-generator driving motor rather than by the rating of the elevator motor, which represents actual but short-time and intermittent full-load current values.

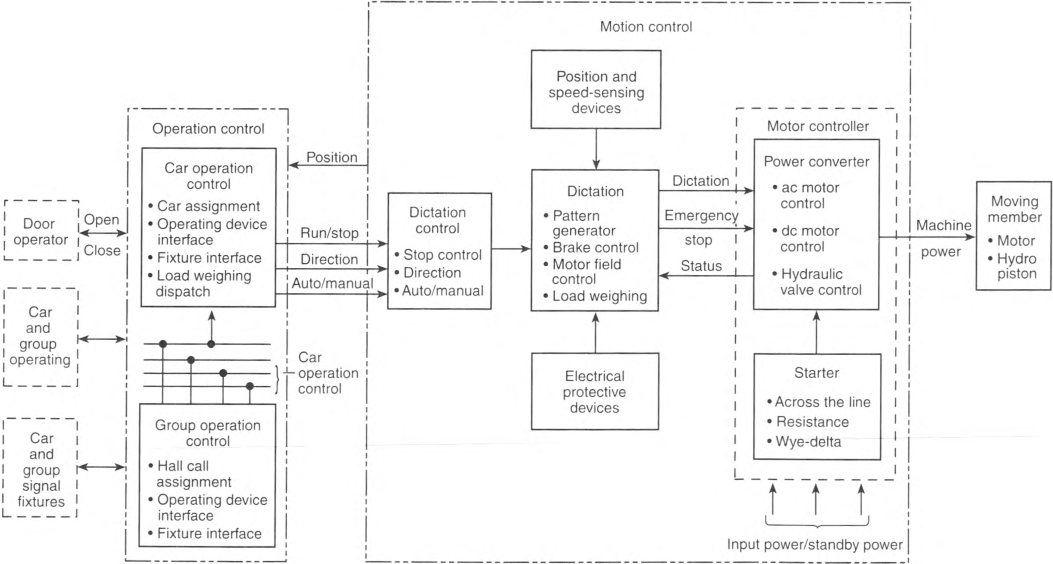

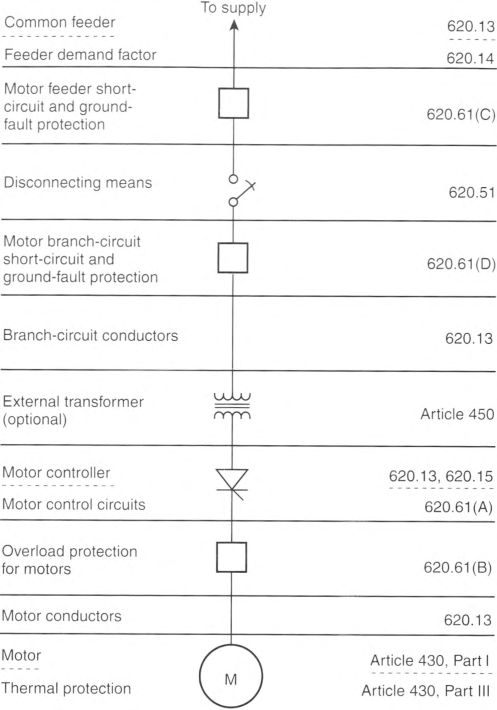

Informational Note No. 2: See Informational Note Figure 620.13.

(A) Conductors Supplying Single Motor.

Conductors supplying a single motor shall have an ampacity not less than the percentage of motor nameplate current determined from 430.22(A) and (E).

Informational Note: Some elevator motor currents, or those motor currents of similar function, exceed the motor nameplate value. Heating of the motor and conductors is dependent on the root-mean square (rms) current value and the length of operation time. Because this motor application is inherently intermittent duty, conductors are sized for duty cycle service as shown in Table 430.22(E).

(B) Conductors Supplying a Single Motor Controller.

Conductors supplying a single motor controller shall have an ampacity not less than the motor controller nameplate current rating, plus all other connected loads. Motor controller nameplate current ratings shall be permitted to be derived based on the rms value of the motor current using an intermittent duty cycle and other control system loads, if present.

(C) Conductors Supplying a Single Power Transformer.

Conductors supplying a single power transformer shall have an ampacity not less than the nameplate current rating of the power transformer plus all other connected loads.

Informational Note No. 1: The nameplate current rating of a power transformer supplying a motor controller reflects the nameplate current rating of the motor controller at line voltage (transformer primary).

Informational Note No. 2: See Informative Annex D, Example No. D10.

(D) Conductors Supplying More Than One Motor, Motor Controller, or Power Transformer.

Conductors supplying more than one motor, motor controller, or power transformer shall have an ampacity not less than the sum of the nameplate current ratings of the equipment plus all other connected loads. The ampere ratings of motors to be used in the summation shall be determined from Table 430.22(E), 430.24, and 430.24, Exception No. 1.

Informational Note: See Informative Annex D, Example Nos. D9 and D10.

Informational Note Figure 620.13 Single-Line Diagram.

620.14 Feeder Demand Factor.

Feeder conductors of less ampacity than required by 620.13 shall be permitted, subject to the requirements of Table 620.14.

Table 620.14 Feeder Demand Factors for Elevators.

| Number of Elevators on a Single Feeder | Demand Factor* |

|---|---|

| 1 | 1.00 |

| 2 | 0.95 |

| 3 | 0.90 |

| 4 | 0.85 |

| 5 | 0.82 |

| 6 | 0.79 |

| 7 | 0.77 |

| 8 | 0.75 |

| 9 | 0.73 |

| 10 or more | 0.72 |

* Demand factors are based on 50 percent duty cycle (i.e., half time on and half time off).

620.15 Motor Controller Rating.

The motor controller rating shall comply with 430.83. The rating shall be permitted to be less than the nominal rating of the elevator motor, when the controller inherently limits the available power to the motor and is marked as power limited.

Informational Note: See 430.8 for controller markings.

620.16 Short-Circuit Current Rating.

(A) Marking.

Where an elevator control panel is installed, it shall be marked with its short-circuit current rating, based on one of the following:

- Short-circuit current rating of a listed assembly

- Short-circuit current rating established utilizing an approved method

Informational Note: UL 508A-2013, Standard for Industrial Control Panels, Supplement SB, is an example of an approved method.

(B) Installation.

The elevator control panel shall not be installed where the available fault current exceeds its short-circuit current rating, as marked in accordance with 620.16(A).

620.21 Wiring Methods.

Conductors, cables, and optical fiber cables located in hoistways, escalator and moving walk wellways, platform lifts, stairway chairlift runways, machinery spaces, control spaces, in or on cars, machine rooms, and control rooms, not including the traveling cables connecting the car or counterweight and hoistway wiring, shall be installed in rigid metal conduit, intermediate metal conduit, electrical metallic tubing, rigid nonmetallic conduit, or wireways, or shall be Type MC, MI, or AC cable unless otherwise permitted in 620.21(A) through (C). Unused conductors in an enclosure shall be insulated or protected from accidental contact with exposed live parts.

Exception: Cords and cables of listed cord-and-plug-connected equipment shall not be required to be installed in a raceway.

Informational Note: When an elevator is classified as a fire service access elevator or occupant evacuation operation elevator, some building codes require additional protection for conductors that are located outside of the elevator hoistway and machine room.

(A) Elevators.

(1) Hoistways and Pits.

- Types CL2P, CL2R, and CL2 cables shall be permitted, provided the cables are supported and protected from physical damage. Substitute cables for Class 2 cables installed in accordance with 722.135(E) shall be permitted.

- Flexible cords and cables that are components of listed equipment and used in circuits operating at 30 volts rms or less or 42 volts dc or less shall be permitted, provided the cords and cables are supported and protected from physical damage and are of a jacketed and flame-retardant type.

- The following wiring methods shall be permitted in the hoistway in lengths not to exceed 1.8 m (6 ft):

- A sump pump or oil recovery pump located in the pit shall be permitted to be cord connected. The cord shall be a hard usage oil-resistant type, of a length not to exceed 1.8 m (6 ft), and shall be located to be protected from physical damage.

- Hard-service cords and junior hard-service cords that conform to the requirements of Article 400 (Table 400.4) shall be permitted as flexible connections between the fixed wiring in the hoistway and hoistway access switches when located in the hoistway door sight guard.

Informational Note: See ASME A17.1-2019/CSA B44-19, Safety Code for Elevators and Escalators.

(2) Cars.

- Flexible metal conduit, liquidtight flexible metal conduit, or liquidtight flexible nonmetallic conduit of metric designator 12 (trade size 3/8), or larger, not exceeding 1.8 m (6 ft) in length, shall be permitted on cars where so located as to be free from oil and if securely fastened in place.Exception: Liquidtight flexible nonmetallic conduit (LFNC-B) of metric designator 12 (trade size 3/8) or larger shall be permitted in lengths in excess of 1.8 m (6 ft).

- Hard-service cords and junior hard-service cords that conform to the requirements of Article 400 (Table 400.4) shall be permitted as flexible connections between the fixed wiring on the car and devices on the car doors or gates. Hard-service cords only shall be permitted as flexible connections for the top-of-car operating device or the car-top work light. Devices or luminaires shall be grounded by means of an equipment grounding conductor run with the circuit conductors. Cables with smaller conductors and other types and thicknesses of insulation and jackets shall be permitted as flexible connections between the fixed wiring on the car and devices on the car doors or gates, if listed for this use.

- Flexible cords and cables that are components of listed equipment and used in circuits operating at 30 volts rms or less or 42 volts dc or less shall be permitted, provided the cords and cables are supported and protected from physical damage and are of a jacketed and flame-retardant type.

- The following wiring methods shall be permitted on the car assembly in lengths not to exceed 1.8 m (6 ft):

- Flexible metal conduit

- Liquidtight flexible metal conduit

- Liquidtight flexible nonmetallic conduit

- Flexible cords and cables, or conductors grouped together and taped or corded, shall be permitted to be installed without a raceway. They shall be located to be protected from physical damage and shall be of a flame retardant type and shall be part of one of the following:

- Listed equipment

- A driving machine

- A driving machine brake

(3) Within Machine Rooms, Control Rooms, and Machinery Spaces and Control Spaces.

- Flexible metal conduit, liquidtight flexible metal conduit, or liquidtight flexible nonmetallic conduit of metric designator 12 (trade size 3/8), or larger, not exceeding 1.8 m (6 ft) in length, shall be permitted between control panels and machine motors, machine brakes, motor-generator sets, disconnecting means, and pumping unit motors and valves.Exception: Liquidtight flexible nonmetallic conduit (LFNC-B) metric designator 12 (trade size 3/8) or larger shall be permitted to be installed in lengths in excess of 1.8 m (6 ft).

- Where motor-generators, machine motors, or pumping unit motors and valves are located adjacent to or underneath control equipment and are provided with extra-length terminal leads not exceeding 1.8 m (6 ft) in length, such leads shall be permitted to be extended to connect directly to controller terminal studs without regard to the carrying capacity requirements of Articles 430 and 445. Auxiliary gutters shall be permitted in machine and control rooms between controllers, starters, and similar apparatus.

- Flexible cords and cables that are components of listed equipment and used in circuits operating at 30 volts rms or less or 42 volts dc or less shall be permitted, provided the cords and cables are supported and protected from physical damage and are of a jacketed and flame-retardant type.

- On existing or listed equipment, conductors shall also be permitted to be grouped together and taped or corded without being installed in a raceway. Such cable groups shall be supported at intervals not over 900 mm (3 ft) and located so as to be protected from physical damage.

- Flexible cords and cables in lengths not to exceed 1.8 m (6 ft) that are of a flame-retardant type and located to be protected from physical damage shall be permitted in these rooms and spaces without being installed in a raceway. They shall be part of one of the following:

- Listed equipment

- A driving machine

- A driving machine brake

(4) Counterweight.

The following wiring methods shall be permitted on the counterweight assembly in lengths not to exceed 1.8 m (6 ft):

- Flexible metal conduit

- Liquidtight flexible metal conduit

- Liquidtight flexible nonmetallic conduit

- Flexible cords and cables, or conductors grouped together and taped or corded, shall be permitted to be installed without a raceway. They shall be located to be protected from physical damage, shall be of a flame retardant type, and shall be part of one of the following:

- Listed equipment

- A driving machine

- A driving machine brake

(B) Escalators.

(1) Wiring Methods.